diagnostics: Flow diagnostics functionality¶

Flow diagnostics refers to a set of simple and controlled numerical flow experiments that are run to probe a reservoir model, establish connections and basic volume estimates, compute dynamic heterogeneity measures, and and quickly provide a qualitative picture of the flow patterns in the reservoir. Flow diagnostics can also be used to compute simplified forecasts of fluid displacement and perform what-if and sensitivity analyzes in parameter regions surrounding preexisting simulations. The module offers a computationally inexpensive alternative to performing full-featured multiphase simulations to rank, compare, and validate reservoir models, upscaling procedures, and optimize production scenarios.

-

Contents¶ Files computeFandPhi - Compute flow-capacity/storage-capacity diagram (F,Phi) computeFandPhiFromDist - Undocumented Utility Function computeLorenz - Compute the Lorenz coefficient computeRTD - Compute residence time distributions based on computed tof-values computeSweep - Compute sweep efficiency versus dimensionless time (PVI) computeTOFandTracer - Compute time-of-flight and tracer distribution using finite-volume scheme. computeTOFandTracerAverage - Executes computeTOFandTracer for a series of states and averages computeTimeOfFlight - Compute time of flight using finite-volume scheme. computeWellPairs - Compute volumes and fluxes associated with each flux pair estimateRTD - Estimate residence time distributions based on computed tof-values expandCoarseWellCompletions - Pseudo-wells for computing flow diagnostics in an upscaled model expandWellCompletions - Pseudo-wells for computation of flow diagnostics for completions interactiveDiagnostics - Launch an interactive diagnostics session plotTOFArrival - Undocumented Utility Function plotTracerBlend - Visualise tracer partitions: gray regions are affected by multiple tracers plotWellAllocationComparison - Plot a panel comparing well-allocation from models with different resolution plotWellAllocationPanel - Plot a panel comparing well-allocation from models with different resolution plotWellPairConnections - Plot lines between wells to show relative flux allocation PostProcessDiagnostics - PostProcessDiagnostics handle class PostProcessDiagnosticsECLIPSE - Launch flow diagnostics postprocessor GUI for ECLIPSE simulation output. PostProcessDiagnosticsMRST - Launch flow diagnostics postprocessor GUI for MRST simulation output. selectTOFRegion - Select a subset of cells based on TOF criteria validateStateForDiagnostics - Validate and fix state for flow diagnostics

-

class

PostProcessDiagnostics(dinput, precomp, varargin)¶ PostProcessDiagnostics handle class

Synopsis:

d = PostProcessDiagnostics(dinput, precomp, varargin)

Description:

Class definition for PostProcessDiagnostics GUI object. Takes a information from a previously run simulation and displays accompanying flow diagnostics and simulation results in an interactive GUI. If no precomputed diagnostics are passed in, diagnostics are calculated internally. Simulations should be processed first using either PostProcessDiagnosticsECLIPSE or PostProcessDiagnosticsMRST.

Parameters: - dinput –

Structure containing the following fields:

- maxTOF - Maximum TOF value.

- G - MRST Grid structure with G.cells.PORV field

- Gs - Simulation Grid (for MRST simulations Gs = G)

- Data - Data structure containing static, dynamic and computed properties.

- precomp – Structure optionally containing array of precomputed diagnostics data for each timestep required. If empty, diagnostics will be calculated when the GUI is run.

Keyword Arguments: style – Optional gui style. Only default has been implemented.

Returns: d – Handle to PostProcessDiagnostics object.

- dinput –

-

PostProcessDiagnosticsECLIPSE(varargin)¶ Launch flow diagnostics postprocessor GUI for ECLIPSE simulation output.

Synopsis:

[d] = PostProcessDiagnosticsECLIPSE(varargin)

Description:

Takes the output of an ECLIPSE simulation and launches the flow diagnostics postprocessor GUI. Optionally the path to the .EGRID file can be passed as an input parameter. If no parameters are given a file dialogue box will be launched to select the .EGRID file.

Keyword Arguments: - steps – Array of timesteps to be displayed in the GUI.

- maxTOF – Maximum TOF value. Default value is 500 years.

- cleanup – true or false. Delete all existing flow diagnostics results from previous runs. Default is false.

- precompute – true or false. Precompute flow diagnostics for all timesteps. Default is true.

Returns: d – Handle to PostProcessDiagnostics object.

See also

-

PostProcessDiagnosticsMRST(problem, varargin)¶ Launch flow diagnostics postprocessor GUI for MRST simulation output.

Synopsis:

[d] = PostProcessDiagnosticsMRST(problem,varargin)

Description:

Takes the output of an MRST simulation problem and launches the flow diagnostics postprocessor GUI. The simulation should already have been run as PostProcessDiagnosticsMRST.m will only look for exisiting output.

Parameters: problem – An MRST simulation problem defined using packSimulationProblem.m.

Keyword Arguments: - steps – Array of timesteps to be displayed in the GUI.

- maxTOF – Maximum TOF value. Default value is 500 years.

- cleanup – true or false. Delete all existing flow diagnostics results from previous runs. Default is false.

- precompute – true or false. Precompute flow diagnostics for all timesteps. Default is true.

- startdate – optionally specify a start date of the format [day month year] e.g. [1 1 2000] for the 1st January 2000.

Returns: d – Handle to PostProcessDiagnostics object.

See also

-

computeFandPhi(arg1, varargin)¶ Compute flow-capacity/storage-capacity diagram (F,Phi)

Synopsis:

[F,Phi] = computeFandPhi(pv, tof) [F,Phi] = computeFandPhi(rtd) [F,Phi] = computeFandPhi(rtd, 'sum', true/false);

Description:

- Compute the flow-capacity/storage-capacity based upon either:

- Pore volumes and time-of-flight values per cell. In this case, Phi is defined as the cumulative pore volume and F is the cumulative flux as function of residence time. Assuming incompressible flow, the instant flux is computed as the ratio of pore volume and the residence time.

- Residence-time distribution. In this case, F is the integral of the RTD values, whereas Phi is the first-order moment (i.e., the integral of the product of time and RTD values).

Making an analogue to 1D displacement theory, the F-Phi curve is the equivalent to a plot of the fractional flow versus saturation. Technical description: see Section 13.2-13.3 in the MRST book, Shavali et al. (SPE 146446), and Shook and Mitchell (SPE 124625)

Parameters: - vol – pore volume, one value per cell

- tof – two-component vector with time-of-flight from injector and time-of-flight from producer, one value per cell

- rtd – structure with residence-time distribution from computeRTD

Returns: F – flow capacity = cumulative flux for increasing time-of-flight values, where the flux per cell is defined from the relation

volume = flux * total_travel_time

Phi – storage capacity = cumulative pore volume for increasing time-of-flight values

See also

-

computeFandPhiFromDist(RTD, varargin)¶ Undocumented Utility Function

-

computeLorenz(F, Phi)¶ Compute the Lorenz coefficient

Synopsis:

Lc = computeLorenz(F, Phi)

Parameters: - F – flow capacity

- Phi – storage capacity

Returns: Lc – the Lorenz coefficient, a popular measure of heterogeneity. It is equal to twice the area under the curve and above the F=Phi line. It varies between 0 (homogeneous displacement) to 1 (infinitely heterogeneous displacement).

See also

-

computeRTD(state, G, pv, D, WP, W, varargin)¶ Compute residence time distributions based on computed tof-values .. rubric:: Synopsis:

dist = computeRTD(state, G, pv, D, WP, W, 'pn1', pv1, ...)

Description:

This function computes well-pair RTDs by simulating an imaginary tracer which ditributes equally among all phases (follows the total flux-field), and follows the flux field given by state. A tracer pulse is injected at injector i at time zero and produced at producer p. The RTD is scaled such that

RTD_{ip}(t) = (rate producer p / total tracer mass) * c_p(t),where c_p(t) is the tracer concentration in producer p.

- With the above scaling the RTD has units [s]^-1

- the integral of the RTD approximates fractional recovery

(produced mass/injected mass)- the mean of the RTD time i-to-p allocation approximates the i-to-p allocation volume

RETURNS: dist - structure with fields

pairIx nreg x 2 each row index to injector/producer t nbin x 1 discrete times values nbin x 1 discrete RTD-values volumes nreg x 1 interaction volume for each well pair allocations nreg x 1 interaction allocation for each well pair injectorFlux ninj injector total rates producerFlux nprod producer total rates- SEE ALSO

- estimateRTD

-

computeSweep(F, Phi)¶ Compute sweep efficiency versus dimensionless time (PVI)

Synopsis:

[Ev,tD] = computeSweep(F, Phi)

Parameters: - F – flow capacity

- Phi – storage capacity

Returns: - tD – dimensionless time (PVI)

- Ev – sweep efficiency. Analogue: 1D displacement using the F-Phi curve as flux funcion

See also

-

computeTOFandTracer(state, G, rock, varargin)¶ Compute time-of-flight and tracer distribution using finite-volume scheme.

Synopsis:

D = computeTOFandTracer(state, G, rock) D = computeTOFandTracer(state, G, rock, 'pn1', pv1, ...)

Description:

- Construct the basis for flow diagnostic by computing

- time-of-flight : nabla·(v T) = phi,

- reverse time-of-flight: -nabla·(v T) = phi,

- stationary tracer : ±nabla·(v C) = 0

using a first-order finite-volume method with upwind flux. A majority vote is also used to partition the volume and assign each cell to a unique tracer. Optionally, the routine can also compute time-of-flight values for each influence region by solving localized time-of-flight equations

nabla·(v C_i T) = phi C_i,where C_i is the tracer concentration of each influence region.

Finally, first arrival time is computed by a graph algorithm.

Parameters: - G – Grid structure.

- rock – Rock data structure. Must contain a valid porosity field, ‘rock.poro’.

- state – Reservoir and well solution structure either properly initialized from functions ‘initResSol’ and ‘initWellSol’ respectively, or the results from a call to function ‘solveIncompFlow’. Must contain valid cell interface fluxes, ‘state.flux’.

- OPTIONAL PARAMETERS (supplied in ‘key’/value pairs):

- wells - Well structure as defined by function ‘addWell’. May be empty

- (i.e., wells = []) which is interpreted as a model without any wells.

- src - Explicit source contributions as defined by function

- ‘addSource’. May be empty (i.e., src = []) which is interpreted as a reservoir model without explicit sources.

- bc - Boundary condition structure as defined by function ‘addBC’.

- This structure accounts for all external boundary conditions to the reservoir flow. May be empty (i.e., bc = []) which is interpreted as all external no-flow (homogeneous Neumann) conditions.

- tracerWells - Logical index vector indicating subset of wells for which

- tracer-fields will be computed. Empty matrix (default) is interpeted as all true, i.e., compute tracer fields for all wells.

- computeWellTOFs - Boolean variable. If true, time-of-flight values are

- computed individually for each influence region by solving

- firstArrival - Boolean variable. If true, compute first-arrival time by

- a graph algorithm.

- solver - Function handle to solver for use in TOF/tracer equations.

- Default (empty) is matlab mldivide (i.e., )

- maxTOF - Maximal TOF thresholding to avoid singular/ill-conditioned

- systems. Default (empty) is 50*PVI (pore-volumes-injected).

- processCycles - Extend TOF thresholding to strongly connected

- components in flux graph by considering Dulmage-Mendelsohn decomposition (dmperm). Recommended for highly cyclic flux fields. Only takes effect if ‘allowInf’ is set to false.

Returns: D – struct that contains the basis for computing flow diagnostics: ‘inj’ - list of injection wells ‘prod’ - list of production wells ‘tof’ - time-of-flight and reverse time-of-flight returned

as an array where the first (G.cells.num x 2) elements contain forward/backward TOF for the whole field, and any other columns optinally contain TOF values for individual influence regions

‘itracer’ - steady-state tracer distribution for injectors ‘ipart’ - tracer partition for injectors ‘ifa’ - first-arrival time injectors ‘ptracer’ - steady-state tracer distribution for producers ‘ppart’ - tracer partition for producers ‘pfa’ - first-arrival time for producers

-

computeTOFandTracerAverage(state, G, rock, varargin)¶ Executes computeTOFandTracer for a series of states and averages

Synopsis:

D = computeTOFandTracerAverage(state, G, rock, 'pn1', pv1, ...)

Description:

Computes time of flight for a series of time steps and avarages.

Parameters: - G – Grid structure.

- rock – Rock data structure. Must contain a valid porosity field, ‘rock.poro’.

- state – Reservoir and well solution structure either properly initialized from functions ‘initResSol’ and ‘initWellSol’ respectively, or the results from a call to function ‘solveIncompFlow’. Must contain valid cell interface fluxes, ‘state.flux’.

Keyword Arguments: - wells – Well structure as defined by function ‘addWell’. May be empty (i.e., wells = []) which is interpreted as a model without any wells.

- dt – List of timesteps to use in averaging

- max_tof – Threshold

- min_tof – Threshold

- Additional parameters will be passed on to ‘computeTOFandTracer’, which

- computes the flow diagnostics. See this function for further documentation.

Returns: D – struct that contains the basis for computing flow diagnostics: ‘inj’ - list of injection wells ‘prod’ - list of production wells ‘tof’ - time-of-flight and reverse time-of-flight returned

as an (G.cells.num x 2) vector

‘itracer’ - steady-state tracer distribution for injectors ‘ipart’ - tracer partition for injectors ‘ptracer’ - steady-state tracer distribution for producers ‘ppart’ - tracer partition for producers ‘isubset’ - flooding volumes which satisfy the min/max tof

thresholds (if set). Represents a kind of frequency.

- ‘psubset’ - drainage volumes which satisfy the min/max tof

thresholds (if set). Represents a kind of frequency.

EXAMPLE:

See also

-

computeTimeOfFlight(state, G, rock, varargin)¶ Compute time of flight using finite-volume scheme.

Synopsis:

T = computeTimeOfFlight(state, G, rock) T = computeTimeOfFlight(state, G, rock, 'pn1', pv1, ...) [T, A] = computeTimeOfFlight(...) [T, A, q] = computeTimeOfFlight(...)

Description:

Compute time-of-flight by solving

v·nabla T = phiusing a first-order finite-volume method with upwind flux. Here, ‘v’ is the Darcy velocity, ‘phi’ is the porosity, and T is time-of-flight. The time-of-flight T(x) is the time it takes an inert particles that is passively advected with the fluid to travel from the nearest inflow point to the point ‘x’ inside the reservoir. For the computation to make sense, inflow points must be specified in terms of inflow boundaries, source terms, wells, or combinations of these.

Parameters: - G – Grid structure.

- rock – Rock data structure. Must contain a valid porosity field, ‘rock.poro’.

- state – Reservoir state structure, must contain valid cell interface fluxes, ‘state.flux’. Typically, ‘state’ will contain the solution produced by a flow solver like ‘incompTPFA’.

- OPTIONAL PARAMETERS (supplied in ‘key’/value pairs):

- wells - Well structure as defined by function ‘addWell’. May be empty

- (i.e., wells = []) which is interpreted as a model without any wells.

- src - Explicit source contributions as defined by function

- ‘addSource’. May be empty (i.e., src = []) which is interpreted as a reservoir model without explicit sources.

- bc - Boundary condition structure as defined by function ‘addBC’.

- This structure accounts for all external boundary conditions to the reservoir flow. May be empty (i.e., bc = []) which is interpreted as all external no-flow (homogeneous Neumann) conditions.

- reverse - Boolean variable. If true, the reverse time-of-flight will be

- computed, i.e., the travel time from a cell inside the reservoir to the nearest outflow point (well, source, or outflow boundary). Default: FALSE, i.e, compute forward tof.

- tracer - Cell-array of cell-index vectors for which to solve a

stationary tracer equation:

nabla·(v C) = 0, C(inflow,t)=1One equation is solved for each vector with tracer injected in the cells with the given indices. Each vector adds one additional right-hand side to the original tof-system. Output given as additional columns in T.

- computeWellTOFs - Boolean variable. If true, time-of-flight values are

computed individually for each influence region by solving equations of the form:

nabla·(v C_i T) = phi C_i, T(inflow)=0where C_i denotes the tracer concentration associated with each individual influence region

- firstArrival - Boolean variable. If true, also compute the first-arrival

- time by a graph algorithm (requires MATLAB R2015b or newer)

-

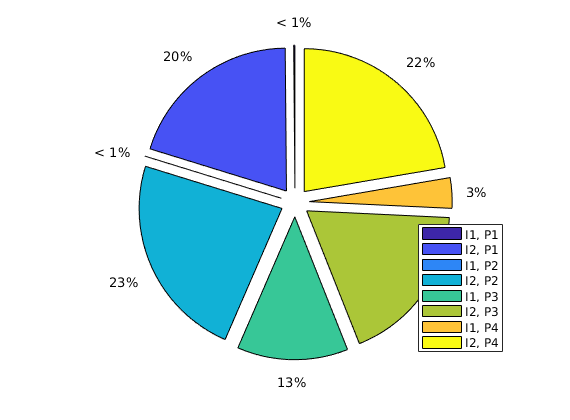

computeWellPairs(state, G, rock, W, D)¶ Compute volumes and fluxes associated with each flux pair

Synopsis:

WP = computeWellPairs(state, G, rock, W, D)

Parameters: - state – Reservoir state

- G – Grid structure.

- rock – Rock data structure. Must contain a valid porosity field, ‘rock.poro’.

- state – Reservoir and well solution structure either properly initialized from functions ‘initResSol’ and ‘initWellSol’ respectively, or the results from a call to function ‘solveIncompFlow’. Must contain valid cell interface fluxes, ‘state.flux’.

- W – Well structure

- D – Struct containing TOF and tracer See documentation of computeTOFandTracer

Returns: WP – struct containing well-pair diagnostics ‘pairs’ - list of well pairs (as text strings using well names) ‘pairsIx’ - list of well pairs (indices in a N_pair x 2 list. Pair

number i has injector pairsIx(i, 1) and producer pairsIx(i, 2)

‘vols’ - pore volumes associated with each pair ‘inj’ - list of structs containing allocation factors for the

injectors

- ‘prod’ - list of structs containing allocation factors for the

producers

The structs that contain flux allocation information consist of the

following data objects –

- ‘alloc’ - nxm array, where n is the number of perforations in

this well and m is the number of wells or segments from the flow diagnostics computation that may potentially contribute to the flux allocation

- ‘ralloc’ - nx1 array containing the well flux that cannot be

attributed to one of the wells/segments accounted for in the flow diagnostics computatation

‘z’ - nx1 array giving the depth of the completions ‘name’ - string with the name of the well or segment

-

estimateRTD(pv, D, WP, varargin)¶ Estimate residence time distributions based on computed tof-values

Synopsis:

dist = estimateRTD(pv, D, WP, 'pn1', pv1, ...)

Description:

This function estmates well-pair RTDs based on computed TOFs and tracer fields. The RDT approximates an imaginary tracer which ditributes equally among all phases (follows the total flux-field). A tracer pulse is injected at injector i at time zero and produced at producer p. The RTD is scaled such that

RTD_{ip}(t) ~= (rate producer p / total tracer mass) * c_p(t),where c_p(t) is the tracer concentration in producer p.

- With the above scaling the RTD has units [s]^-1

- the integral of the RTD approximates fractional recovery

(produced mass/injected mass)- the mean of the RTD time i-to-p allocation approximates the i-to-p allocation volume

Returns: dist – structure with fields pairIx nreg x 2 each row index to injector/producer t nbin x 1 discrete times values nbin x 1 discrete RTD-values volumes nreg x 1 interaction volume for each well pair allocations nreg x 1 interaction allocation for each well pair injectorFlux ninj injector total rates producerFlux nprod producer total rates - SEE ALSO

- computeRTD

-

expandCoarseWellCompletions(xc, WC, Wdf, p)¶ Pseudo-wells for computing flow diagnostics in an upscaled model

Synopsis:

[xn, Wn] = expandCoarseWellCompletions(xc, Wc, Wdf, p)

Parameters: - xc – Reservoir and well solution structure either properly initialized from functions ‘initResSol’ and ‘initWellSol’, respectively, or the results from a call to function ‘solveIncompFlow’. Must contain valid cell interface fluxes, ‘state.flux’.

- Wc – Well structure as defined by function ‘addWell’.

- Wdf – Expanded well structure used for flow diagnostics computation in the underlying fine-scale model, typically the result of a call to ‘expandWellCompletions’.

- p – partition vector describing the coarse-scale partition (i.e., the mapping from the fine grid to the coarse grid)

Returns: - Wn – Well structure containing the pseudo wells

- xn – Reservoir and solution structure corresponding

-

expandWellCompletions(state, W, expansion, split)¶ Pseudo-wells for computation of flow diagnostics for completions

Synopsis:

[xn, Wn] = expandWellCompletions(x, W, c)

Description:

The routines in the flow diagnostic module compute time-of-flight, tracer partition, and well-pair information associated with the whole completion set of each individual well. To compute flow diagnostics for subsets of the well completion, the corresponding well must be replaced by a set of pseudo wells, one for each desired completion interval.

Parameters: - x – Reservoir and well solution structure either properly initialized from functions ‘initResSol’ and ‘initWellSol’, respectively, or the results from a call to function ‘solveIncompFlow’. Must contain valid cell interface fluxes, ‘state.flux’.

- W – Well structure as defined by function ‘addWell’.

- expansion –

Either of two alternatives:

- nx2 vector that specifies how to expand individual wells into a set of pseudo wells. That is, the completions of well number c(i,1) are assigned to c(i,2) bins using a load-balanced linear distribution and then the well is replaced with c(i,2) pseudo wells, one for each bin of completions.

- Cell array of length n. Entry number i in this cell array should be the same length as W(i).cells and contain the bins that will be used to expand the well.

Returns: - Wn – Well structure containing the pseudo wells

- xn – Reservoir and solution structure corresponding

See also

-

interactiveDiagnostics(G, rock, W, varargin)¶ Launch an interactive diagnostics session

Synopsis:

interactiveDiagnostics(G, rock, W); interactiveDiagnostics(G, rock, W, 'state', state) interactiveDiagnostics(G, rock, W, dataset, 'state', state)

Description:

This function launches an interactive session for doing flow diagnostics. The functionality differs slightly based on the input arguments given:

- If a dataset is given, this set of cellwise data will be available for visualization.

- If a state is given, this state will allow for visualization of the component ratios inside a drainage volume. The flux from this state can also be used to calculate time of flight if “computeFlux” is disabled, for instance if the user has some external means of computing fluxes.

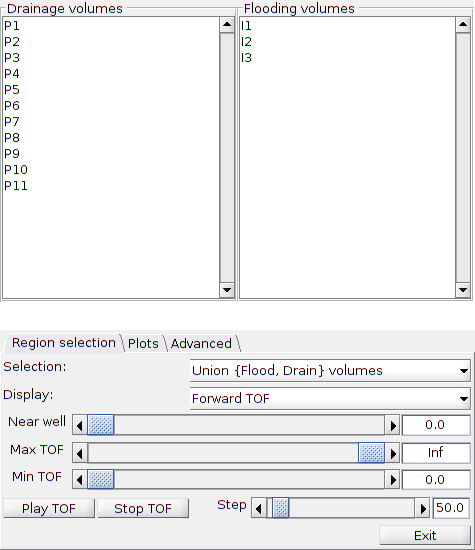

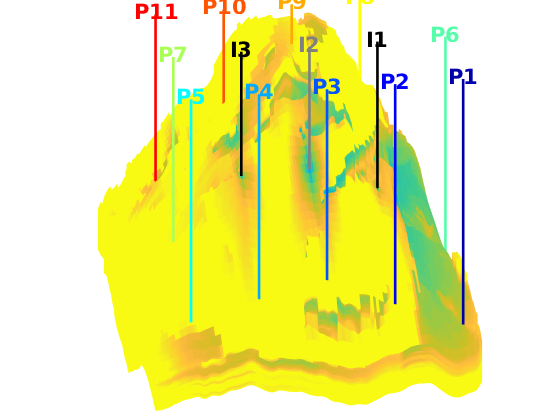

- Once the initialization is complete, two windows will be produced:

A plotting window, showing the reservoir along with the wells and visualized quantities. In the plotting window, it is possible to click wells to get additional information, such as the allocation factors per perforation in the well, the phase distribution grouped by time of flight and the corresponding pore volumes swept/drained.

A controller window which is used to alter the state of the plotting window:

1) Wells can be selected for display (if a well is selected, the corresponding drainage (producer) or flooding (injector) volumes will be visualized. A simple playback function can be used to show propagation of time of flight. Different quantities can be visualized to get a better understanding of the system.

2) A set of buttons provide (experimental) well editing, access to visualization of the well pair connections, Phi/F diagram with Lorenz’ coefficient etc.

3) A player controller (experimental), if a time-series of wells (and states) are supplied.

Parameters: - G – Valid grid structure.

- rock – Rock with valid permeability and porosity fields.

- W – A set of wells which are compatible with the incompTPFA solver.

Keyword Arguments: - ‘state’ – Reservoir state containing fluid saturations and optionally flux and pressure (if ‘computeFlux’ is false)

- ‘computeGrid’ – Use G for plotting, but computeGrid for computing time-of-flight, tracer partitions, etc.

- ‘tracerfluid’ – Fluid used for tracer computation. This defaults to a trivial single-phase fluid.

- ‘fluid’ – Fluid used for mobility calculations if ‘useMobilityArrival’ is enabled.

- ‘LinSolve’ – Linear solver for pressure systems. Defaults: mldivide

- ‘computeFlux’ – If set to false, fluxes are extracted from the provided state keyword argument. This requires a state to be provided and can be used if the fluxes are computed externally (for instance from a expensive full-physics simulation)

- ‘useMobilityArrival’ – If the well plot showing nearby saturations should plot mobility instead of saturations. This may be interesting in some cases because the mobile fluids are more likely to be extracted. However, this plot is often dominated by very mobile gas regions.

- ‘daspect’ – Data aspect ratio, in a format understood by daspect()

- ‘name’ – Name to use for windows

- ‘leaveOpenOnClose’ – Default false. Leaves all figures open when closing the controller.

- ‘fastRotate’ – Enables fast rotate if true, disables if false. Default is enabled for models with > 50000 cells, disabled otherwise.

Returns: Nothing. Creates two figures.

Example:

G = computeGeometry(cartGrid([10, 10, 2])); rock = struct('poro', ones(G.cells.num, 1), 'perm', ones(G.cells.num, 1)*darcy) W = verticalWell([], G, rock, 1, 1, [], 'Val', 1) W = verticalWell(W, G, rock, 1, 10, [], 'Val', 1) W = verticalWell(W, G, rock, 10, 1, [], 'Val', 1) W = verticalWell(W, G, rock, 10, 10, [], 'Val', 1) W = verticalWell(W, G, rock, 5, 5, [], 'Val', 0) interactiveDiagnostics(G, rock, W);

See also

Diagnosticsexamples

-

plotTOFArrival(state, W, pv, fluid, prod, D, varargin)¶ Undocumented Utility Function

-

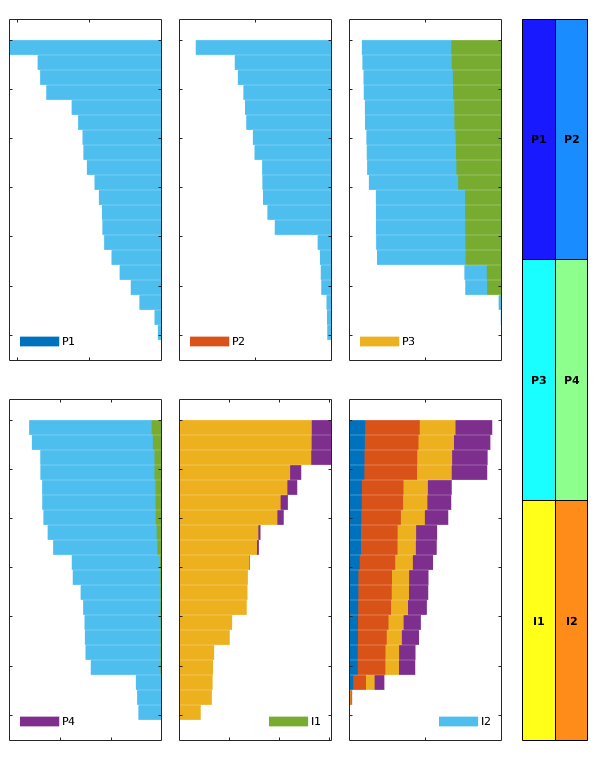

plotTracerBlend(G, partition, maxconc, varargin)¶ Visualise tracer partitions: gray regions are affected by multiple tracers

Synopsis:

plotTracerBlend(G, partition, maxconc) plotTracerBlend(G, partition, maxconc, 'pn1', pv1, ...) h = plotTracerBlend(...)

Parameters: - G – Grid structure partitioned by tracers.

- partition – Tracer partition structure. This is the field ‘.ppart’ (or ‘.ipart’) of the diagnostics structure constructed by function ‘computeTOFandTracer’. One non-negative (integral) value for each grid cell.

- maxconc – Maximum tracer concentration. One scalar value for each grid cell. This value is typically MAX(D.ptracer, [], 2).

- 'pn'/pv –

List of ‘key’/value pairs defining optional parameters. The supported options are:

- p –

Power by which to amplify smearing effects. Note

that the amplification power is applied to a

decreasing function of concentration, so to highlight

regions of smearing, small (but positive) powers

should be used. Using p = 0.2 works well in the case

of secondary production on the Tarbert layers of

SPE10.

Default value: p = 1. No special highlighting or amplification of smearing regions.

- alpha – Alpha factor to modify colormap for tracer. The colormap is by default set to be from the colorcube function. By specifying a value 0<alpha<=1, you can blend these colors with white to brigthen the colormap.

- cells – List of cells as expected by plotCellData()

- cmap – Colormap. Defaults to colorcube

- p –

Power by which to amplify smearing effects. Note

that the amplification power is applied to a

decreasing function of concentration, so to highlight

regions of smearing, small (but positive) powers

should be used. Using p = 0.2 works well in the case

of secondary production on the Tarbert layers of

SPE10.

- non (Any) – matching parameter is passed through to plotCellData().

Returns: h – Patch handle as defined by function ‘plotCellData’. Only returned if specifically requested.

Example:

[G, W, rock] = getSPE10setup(1:10); is_pos = rock.poro > 0; rock.poro(~is_pos) = min(rock.poro(is_pos)); T = computeTrans(G, rock); fluid = initSingleFluid('mu' , 1*centi*poise, ... 'rho', 1000*kilogram/meter^3); state = incompTPFA(initState(G, W, 0), G, T, fluid, 'wells', W); D = computeTOFandTracer(state, G, rock, 'wells', W); plotTracerBlend(G, D.ppart, max(D.ptracer, [], 2)) axis equal tight off, set(gca, 'DataAspectRatio', [ 1, 1, 0.1 ])

See also

-

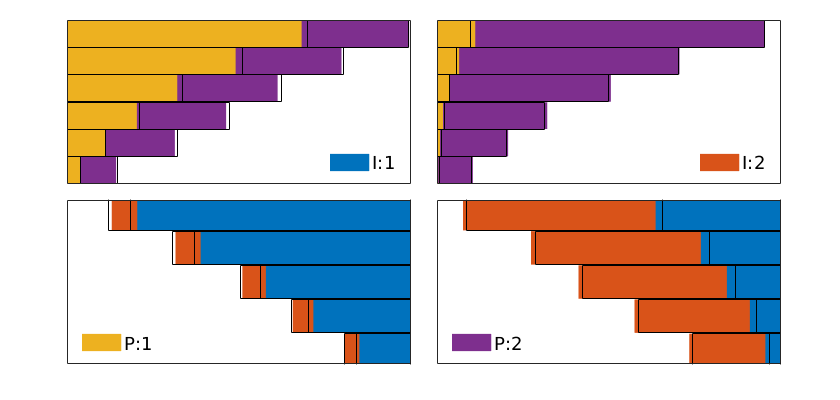

plotWellAllocationComparison(D1, WP1, D2, WP2, varargin)¶ Plot a panel comparing well-allocation from models with different resolution

- SYNOPSIS

- plotWellAllocationComparision(D1, WP1, D2, WP2)

Parameters: - D2 (D1,) – data structure with basic data for flow diagnostics computed by a call to ‘computeTOFandTracer’ for model 1 and model 2

- WP2 (WP1,) – data structure containing information about well pairs, computed by a call to ‘computeWellPairs’

Description:

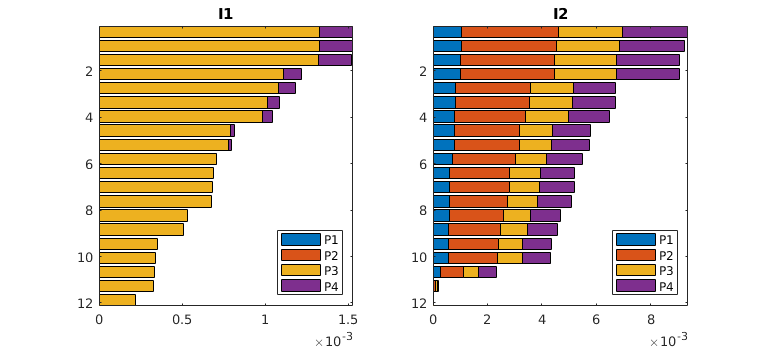

The routine makes a bar plot for each well segment that is represented in the input data D/WP. (There is no check that the well segments in D1 and D2 are the same). For injection wells, the bars represent the cumulative outfluxes, from the bottom to the top of the segment, that have been attributed to the different producers. The bars are shown in color for model 1, with a unique color representing each of the segments of the producers, and in solid black lines for model 2. For the production wells, the bars represent influxes that can be attributed to different injector segments. If the two models predict the same flux allocation, the color bars and the solid lines should be matching.

If D2 and WP2 are empty, a graph is produced that shows the well allocation for the wells in WP1.

See also

computeTOFandTracer,computeWellParis,expandWellCompletions

-

plotWellAllocationPanel(D, WP, varargin)¶ Plot a panel comparing well-allocation from models with different resolution

- SYNOPSIS

- plotWellAllocationPanel(D, WP)

Parameters: - D – data structure with basic data for flow diagnostics computed by a call to ‘computeTOFandTracer’

- WP – data structure containing information about well pairs, computed by a call to ‘computeWellPairs’

Description:

The routine makes a bar plot for each well segment that is represented in the input data D/WP. For injection wells, the bars represent the cumulative outfluxes, from the bottom to the top of the segment, that have been attributed to the different producers. The bars are shown in color with a unique color representing each of the segments of the producers. For the production wells, the bars represent influxes that can be attributed to different injector segments.

-

plotWellPairConnections(G, WP, D, W, pv, minAlloc)¶ Plot lines between wells to show relative flux allocation

- SYNOPSIS

- plotWellPairConnections(G, WP, D, W, pv) plotWellPairConnections(G, WP, D, W, pv, mA)

Parameters: - G – Grid structure.

- WP – data structure containing information about well pairs, computed by a call to ‘computeWellPairs’

- D – data structure with basic data for flow diagnostics computed by a call to ‘computeTOFandTracer’

- W – Well structure as defined by function ‘addWell’.

- pv – vector with pore volume as computed by ‘poreVolume(G,rock)’

- mA – disregard connections with relative allocation below mA

Description:

The routine makes a curved line between each well pair, where the thickness of the line is proportional to the relative flux allocation for this pair.

See also

-

selectTOFRegion(D, max_tof, min_tof, varargin)¶ Select a subset of cells based on TOF criteria

Synopsis:

selectTOFRegion(D, max_tof, min_tof, ...);

Description:

Selects a subset of a grid based on TOF information and selection criteria.

Parameters: - D – Time of flight object computed by computeTOFandTracer.

- max_tof – All TOF-regions higher than this will be discarded.

- min_tof – All TOF-regions less than this will be discarded.

Keyword Arguments: - ‘drain_wells’ – List of draining (production) wells to consider. Other wells will be ignored

- ‘flood_wells’ – List of flooding (injecting) wells to consider. Other wells will be ignored

- ‘set_op’ – Operation op to perform, so that the computed selection is op(flood, drain) where flood and drain are the flooding and drainage volumes, respectively.

- ‘near_well_max_tof’ – Threshold for near well regions to include. Set to zero to disable including near-well regions.

- ‘psubset’ – User specified draining / production region to consider. When this is enabled, max_tof and min_tof will not be used to find the selected drainage region.

- ‘isubset’ – User specified flooding / injection region to consider. When this is enabled, max_tof and min_tof will not be used to find the selected flooding region.

- ‘tracer_threshold’ – Tracer-value threshold for including in region. For ‘intersection’, threshold applies to product of inj/prod tracers. Default value: 0.05;

Returns: A list of cell indices

EXAMPLE:

SEE ALSO:

-

validateStateForDiagnostics(state)¶ Validate and fix state for flow diagnostics

Synopsis:

state = validateStateForDiagnostics(state)

Description:

Routine for ensuring that states are suitable for diagnostic routines. Not all solvers produce the “flux” fields directly, but may instead give component fluxes that must be combined to form the flux. This routine will, if possible, ensure that flux exists in the state.

Parameters: state – State produced by one of MRST’s solvers. Returns: state – State with flux at wellSol and interfaces, if possible. Note

This routine will throw an error if there is insufficient data to produce the correct fields.

See also

-

Contents¶ OPTIMIZATION

- Files

- argmaxCubic - find max of cubic polynom through p1, p2 computeDefaultBasis - Undocumented Utility Function control2well - Update val-fields of W from controls u evalObjectiveDiagnostics - Undocumented Utility Function getObjectiveDiagnostics - Get an objective function for the diagnostics optimization routines lineSearch - lineSearch – helper function which performs line search based on linsolveWithTimings - Undocumented Utility Function optimizeDiagnosticsBFGS - Optimize well rates/bhps to minimize/maximize objective optimizeTOF - Optimize well rates based on diagnostics-based objective function optimizeWellPlacementDiagnostics - Optimize the placement of wells using flow diagnostics plotWellRates - Simple utility for plotting well rates. Used by optimizeTOF. plotWellsPrint - Plots wells as simple colored circles. Helper for diagnostics examples. solveStationaryPressure - Solve incompressible, stationary pressure without gravity with optional TOF output SolveTOFEqsADI - Solve the time of flight equations for solveStationaryPressure. tofRobustFix - Presently does nothing. Can be overriden if needed. unitBoxBFGS - Undocumented Utility Function well2control - Produce control vector u from target-wells

-

SolveTOFEqsADI(eqs, state, W, computeTracer, linsolve)¶ Solve the time of flight equations for solveStationaryPressure.

Synopsis:

D = SolveTOFEqsADI(eqs, state, W, true)

Description:

Solves tof/tracer problems efficiently for solveStationaryPressure. This function is primarily meant to be called from other functions and the interface reflects this. For a more general time of flight solver, see computeTOFandTracer.

Parameters: - eqs – Residual equations for pressure, time of flight and tracer.

- state – Reservoir state

- W – The wells for which tracers are to be computed.

- computeTracer – Boolean indicating if tracers are required.

Returns: D – Time of flight / tracer structure.

-

argmaxCubic(p1, p2)¶ find max of cubic polynom through p1, p2

-

computeDefaultBasis(basis, G, state, system, W, fluid, pv, T, varargin)¶ Undocumented Utility Function

-

control2well(u, W, varargin)¶ Update val-fields of W from controls u If scaling is supplied, u is assumed to be scaled control s.t. 0<=u<=1 according to scaling.boxLims

-

evalObjectiveDiagnostics(u, obj, state, system, G, fluid, pv, T, W, scaling, varargin)¶ Undocumented Utility Function

-

getObjectiveDiagnostics(G, rock, type, varargin)¶ Get an objective function for the diagnostics optimization routines

Synopsis:

obj = getObjectiveDiagnostics(G, rock, 'minlorenz')

DESCRIPTION: This function produces a function handle that is a realization of some objective function based on quantities used in flow diagnostics, that is:

- Pressure

- Reservoir fluxes

- Well fluxes and bottom hole pressure

- Forward / backward time of flight

- Well tracers (production / injection are treated seperately)

The returned function handle will accept input in the form

value = obj(state, D)where state is the reservoir state and D the flow diagnostics object containing time of flight and tracer values. The ‘D’ struct can be returned from solveStationaryPressure or computeTOFandTracer and the state may come from any pressure solver contained in MRST. Most of the optimization routines get both these quantities from solveStationaryPressure, which is the recommended way of evaluating the objective functions if gradients are required.

The value return will be an instance of the ADI class and contains both the objective function value as well as gradients with respect to time of flight etc. The treatment is consistent with the ordering used in solveStationaryPressure.

Parameters: - G – The grid which will be used to evaluate the objective function

- rock – Rock with valid <poro> field containing the porosity. Several of the included objective functions use the pore volumes.

- type –

Either:

A string indicating the type of objective functions. Currently the available functions include, ‘minlorenz’ - Minimize the Lorenz’ coefficient,or

A function handle which accepts a single struct argument containing the fields

’pressure’: Reservoir pressure ‘state’: Full reservoir state ‘pv’ : Pore volume ‘fluxes’: Well fluxes ‘bhp’: Well bottom hole pressures ‘forward_tof’: Time of flight originating from injectors ‘backward_tof’:Time of flight originating from producersThis option is primarily intended for rapid experimentation, i.e. allowing someone who knows what they are doing to define objective functions on the fly in the form

tmp = @(packed) sqrt(sum(packed.forward_tof.^2))

obj = getObjectiveDiagnostics(G, rock, tmp)

which would make obj an objective function that is now the norm of the forward time of flight, and can be used to optimize well rates and placement.

Keyword Arguments: - Any optional parameters are passed onto the objective function.

- Different objective functions handle different parameters.

Returns: obj – Function handle accepting state and D struct.

-

lineSearch(u0, v0, g0, d, f, opt)¶ lineSearch – helper function which performs line search based on Wolfe-conditions.

SYNOPSIS: [u, v, g, info] = lineSearch(u0, v0, g0, d, f, opt)

PARAMETERS: u0 : current control vector v0 : current objective value g0 : current gradient d : search direction, returns an error unless d’*g0 > 0 f : objective function s.t. [v,g] = f(u) opt: struct of parameters for line search

RETURNS: u : control vector found along d v : objective value for u g : gradient for u info : struct containing fields:

- flag : 1 for success (Wolfe conditions satisfied)

- -1 max step-length reached without satisfying Wolfe-conds -2 line search failed in maxIt iterations (returns most recent control without further considerations)

step : step-length nits : number of iterations used

-

linsolveWithTimings(A, x, linsolve)¶ Undocumented Utility Function

-

optimizeDiagnosticsBFGS(G, W, fluid, pv, T, s, state, boxLims, objective, varargin)¶ Optimize well rates/bhps to minimize/maximize objective

Synopsis:

[W_best, D_init, D_best] = optimizeDiagnosticsBFGS(G, W, fluid, pv, T, s, state, minRate, objective)

Description:

Optimizes well rates/bhps as defined in W. The optimization process is based on BFGS where the search direction is projected onto the feasible domain as given by boxLims (upper/lower value for each control).

- boxLims must be supplied for all target wells.

Parameters: - G – Valid grid structure.

- W – Well configuration suitable for AD-solvers.

- fluid – AD-fluid, for instance defined by initSimpleADIFluid. This is used to evalute relperm / viscosity when calculating fluxes.

- pv – Pore volume. Typicall output from poreVolume(G, rock).

- s – AD system. See initADISystem.

- state – Reservoir state as defined by initResSol.

- boxLims – Lower and upper limit for each target well

- objective – Objective function handle. Should have the interface @(state, D) where D is a diagnostics object (see computeTOFandTracer for the expected fields) and return a single numerical value along with its Jacobian. See getObjectiveDiagnostics for examples.

Keyword Arguments: maxiter – Maximum number of attempts to find an improvement. If maxiter successive evaluations fail to improve upon the last optimum, the function returns.

alpha – Adjustment for scaling the initial relaxation factor in the optimization algorithm. This can improve convergence if the problem if chosen wisely, but the default is fairly robust since it is based on the magnitude of the initial objective as well as the gradients of the well at i = 0.

targets – Index into W argument of wells that are to be optimized. They must all be initially the same type (i.e. producers / injectors) and they should be rate controlled. This defaults to all injectors with rate controls.

deltatol – Termination criterion. If the relative change between iterations falls below this number, the function returns. For instance, if deltatol is 0.05, if the relative change between evaluations is less than 5% in absolute value, the iteration completes.

plotProgress – Plots the well rates and function evaluations during the well optimization process.

verbose – Controls the amount of output produced by the routine.

linsolve – The linear solver used to solve the elliptic pressure systems during the optimization with a interface on the form @(A, b) for the linear system Ax=b. Fast multigrid or multiscale methods will significantly improve upon the solution speed for larger problems.

alphamod – The modifier used to adjust alpha during the process. If a step is unsuccessful,

alpha <- alpha/alphamod

and the step is retried. If a step is successful, the next initial alpha is set to

alpha <- alpha*alphamod.

Returns: D_best – The flow diagnostics object corresponding to the best evaluated well configuration.

W_best – The best well configuration

history – A struct containing the optimization history in the fields: D - Diagnostic objects for all steps that reduced the objective function.

- values - Values per target well. One row per element in

the D array.

- gradient - One gradient per diagnostics object. The

objective function value for step i can be found at history.gradient(1).objective.val.

- iterations - Iteration per step required to improve

upon the previous minimum.

-

optimizeTOF(G, W, fluid, pv, T, op, state, minRates, objective, varargin)¶ Optimize well rates based on diagnostics-based objective function

Synopsis:

[D_best, W_best, history] = optimizeTOF(G, W, fluid, pv, T, s, state, minRate, objective) [D_best, W_best, history] = optimizeTOF(G, W, fluid, pv, T, s, state, minRate, objective, 'targets', [1, 3, 9])

Description:

Optimizes well rates. The optimization process is based on steepest descent given a gradient, and uses the following constraints to perform the optimization:

- Sum of rates of the targets are constant, i.e. the total

injected/produced volume of the targets remains constant throughout the optimization.

- All target wells must have a minimum rate which ensures that they do

not change from injectors to producers during the optimization process. This can be specified for all wells simultanously, or well specific limits can be provided.

The progress of the optimization can be visualized during the process (see optional parameters below)

Parameters: - G – Valid grid structure.

- W – Well configuration suitable for AD-solvers.

- fluid – AD-fluid, for instance defined by initSimpleADIFluid. This is used to evalute relperm / viscosity when calculating fluxes.

- pv – Pore volume. Typicall output from poreVolume(G, rock).

- op – Operators from setupOperatorsTPFA

- state – Reservoir state as defined by initResSol.

- minRates – Either a single value for the minimum well rate, or a value per target well (see ‘targets’ keyword)

- objective – Objective function handle. Should have the interface @(state, D) where D is a diagnostics object (see computeTOFandTracer for the expected fields) and return a single numerical value along with its Jacobian. See getObjectiveDiagnostics for examples.

Keyword Arguments: maxiter – Maximum number of attempts to find an improvement. If maxiter successive evaluations fail to improve upon the last optimum, the function returns.

alpha – Adjustment for scaling the initial relaxation factor in the optimization algorithm. This can improve convergence if the problem if chosen wisely, but the default is fairly robust since it is based on the magnitude of the initial objective as well as the gradients of the well at i = 0.

targets – Index into W argument of wells that are to be optimized. They must all be initially the same type (i.e. producers / injectors) and they should be rate controlled. This defaults to all injectors with rate controls.

deltatol – Termination criterion. If the relative change between iterations falls below this number, the function returns. For instance, if deltatol is 0.05, if the relative change between evaluations is less than 5% in absolute value, the iteration completes.

plotProgress – Plots the well rates and function evaluations during the well optimization process.

verbose – Controls the amount of output produced by the routine.

linsolve – The linear solver used to solve the elliptic pressure systems during the optimization with a interface on the form @(A, b) for the linear system Ax=b. Fast multigrid or multiscale methods will significantly improve upon the solution speed for larger problems.

alphamod – The modifier used to adjust alpha during the process. If a step is unsuccessful,

alpha <- alpha/alphamod

and the step is retried. If a step is successful, the next initial alpha is set to

alpha <- alpha*alphamod.

Returns: D_best – The flow diagnostics object corresponding to the best evaluated well configuration.

W_best – The best well configuration

history – A struct containing the optimization history in the fields: D - Diagnostic objects for all steps that reduced the objective function.

- values - Values per target well. One row per element in

the D array.

- gradient - One gradient per diagnostics object. The

objective function value for step i can be found at history.gradient(1).objective.val.

- iterations - Iteration per step required to improve

upon the previous minimum.

-

optimizeWellPlacementDiagnostics(G, W, rock, objective, targetWells, D, wlimit, state0, fluid_ad, pv, T, s, varargin)¶ Optimize the placement of wells using flow diagnostics

Synopsis:

W = optimizeWellPlacementDiagnostics(G, W, rock, objective, targetWells,... D, wlimit, state0, fluid_ad, pv, T, s)

Description:

This function optimizes the controls of some set of wells using fast-to-evalute diagnostic proxy models.

Parameters: - G – Grid structure.

- W – Well structured as defined by addWell.

- rock – Rock with valied perm field. Used to calculate well indices for new well positions.

- objective – Objective function as defined by getObjectiveDiagnostics.

- targetWells – Indices into W indicating which wells are to be optimized. If the rates and placement are to be optimized, all targets must be of the same kind (i.e. all injectors or producers) as the algorithm assumes that the total injected fluid is constant.

- D – Struct of diagnostics quantities. Unused.

- wlimit – Well limits.- Passed onto optimizeTOF if optimizeSubsteps is enabled.

- state0 – Initial state as defined by for example initResSol.

- fluid_ad – Valid ad_fluid. See initSimpleADIFluid.

- pv – Pore volume.

- T – Half-transmissibilities as produced by computeTrans.

- s – AD system. See initADISystem.

Keyword Arguments: - maxIter – Maximum outer iterations. An outer iteration does a single pass over all wells, moving them until they improve the solution or they reach the wellSteps constraint.

- optimizeSubsteps – Optimize the rates of the wells after each placement. This may increase the complexity substatially!

- searchRadius – How large logical region should be used to evaluate candidate wells. The larger the region, the faster the convergence for simple cases, but at the same time the optimization assumptions may be less valid the further away from current wells a ghost well is moved. Should be carefully adjusted.

- searchIncrement – How many ghost wells should be placed? As adding wells is a bit costly, this allows coarser grained ghost well placement inside the searchRadius. If the search radius is 10 in each ij-direction and searchIncrement is set to 5, 4*4 = 16 ghost wells will be equally spaced.

Returns: - W – Optimized wells.

- wellHistory – numel(W) long array containing the visitation history of each well for plotting or debugging.

- history – Optimization history (if optimizeSubsteps is active). One entry per optimization leading to improvement.

-

plotWellRates(W, data, varargin)¶ Simple utility for plotting well rates. Used by optimizeTOF.

-

plotWellsPrint(G, W, D)¶ Plots wells as simple colored circles. Helper for diagnostics examples.

-

solveStationaryPressure(G, state, operators, W, fluid, pv, T, varargin)¶ Solve incompressible, stationary pressure without gravity with optional TOF output

Synopsis:

% Compute pressure state = solveStationaryPressure(G, state, ops, W, f, pv, T) % Compute pressure and time of flight / well tracers [state, D] = solveStationaryPressure(G, state, ops, W, f, pv, T) % Compute pressure, tof/tracer and the well control gradients wrt some objective function [state, D, grad] = solveStationaryPressure(G, state, ops, W, f, pv, T, 'objective', obj)

Description:

This function is the primary solver for several optimization routines in the diagnostics module. It serves as a convenient pressure solver, time of flight / tracer solver and gradient evaluator rolled up in one. The functionality provided and computational complexity depends on the output arguments.

Parameters: - G – Grid structure.

- state – Reservoir and well solution structure either properly initialized from functions ‘initResSol’ and ‘initWellSol’ respectively, or the results from a previous call to function ‘incompTPFA’ and, possibly, a transport solver such as function ‘implicitTransport’.

- ops – Operators from e.g. setupOperatorsTPFA

- W – The well configuration to be used. Unlike many of the other solvers in MRST, the wells are required and are the only way of driving flow in this solver. This is because solveStationaryPressure is designed to be used for well optimization. Although it is quite possible to use it as a standalone pressure solver for incompressible problems with wells, other choices are likely better and faster if no gradients or time of flight are required (see incompTPFA).

- fluid – Valid AD fluid object. For simple instances, consider initSimpleADIFluid

Keyword Arguments: objective – Objective function handle as defined by getObjectiveDiagnostics. Should use the interface

@(state, D)

maxiter – Maximum number of iterations. Currently not in use, but may become active in the event that this solver starts to support compressibility some time in the future.

linsolve –

- Linear solver supporting the syntax x = linsolve(A,b).

Elliptic pressure problems that are fairly large may be efficiently solved with algebraic multigrid if a function is provided. This function provides SPD systems.

- src - Source terms. Array of G.cells.num x 1. This implementation

will likely change.

- computeTracer - Defines if tracers are to be solved for wells, if

requested through variable output count. Default: TRUE.

Returns: - state – Update reservoir and well solution structure with new values

- for the fields:

- pressure – Pressure values for all cells in the

discretised reservoir model, ‘G’.

- flux – Flux across global interfaces corresponding to

the rows of ‘G.faces.neighbors’.%

- wellSol – Well solution structure array, one element for

each well in the model, with new values for the fields:

- flux – Perforation fluxes through all

- perforations for corresponding well. The fluxes are interpreted as injection fluxes, meaning positive values correspond to injection into reservoir while negative values mean production/extraction out of reservoir.

- pressure – Well bottom-hole pressure.

- D (OPTIONAL) - Diagnostics struct. See computeTOFandTracer. Requesting

this output means additional non-trivial computations will be performed.

- grad (OPTIONAL) - Gradient of the objective function with regards to the

different well controls. An objective function must obviously be provided for this to work.

-

tofRobustFix(A)¶ Presently does nothing. Can be overriden if needed.

-

unitBoxBFGS(u0, f, varargin)¶ Undocumented Utility Function

-

well2control(W, varargin)¶ Produce control vector u from target-wells If scaling is supplied, u is scaled s.t. 0<=u<=1 according to scaling.boxLims

Examples¶

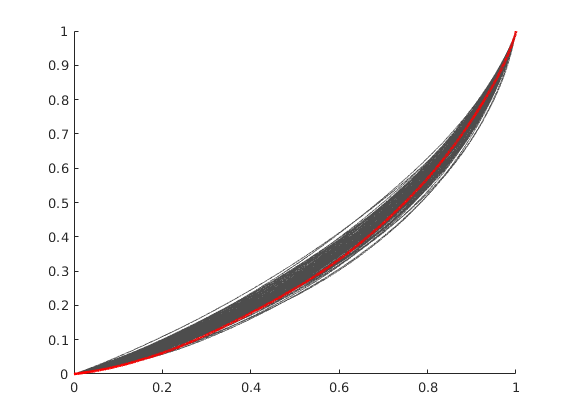

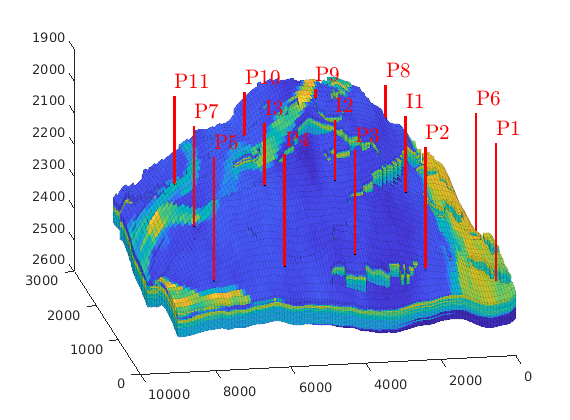

Ranking of different realizations of the same model¶

Generated from diagnostEggModel.m

The Egg model contains a large number of different realizations of the same permeability field. We can use flow diagnostics to efficiently rank the different models. We recommend that you are familiar with the basic concepts of flow diagnostics as demonstreated by the diagnostIntro example. For details on the EggModel and the corresponding ensemble, see Jansen, J. D., et al. “The egg model–a geological ensemble for reservoir simulation.” Geoscience Data Journal 1.2 (2014): 192-195.

We first solve the base case using a pressure solver¶

Set up pressure solver and solve base case.

mrstModule add deckformat ad-blackoil ad-core blackoil-sequential diagnostics

[G, rock, fluid, deck, state0] = setupEGG('realization', 0);

model = PressureOilWaterModel(G, rock, fluid);

schedule = convertDeckScheduleToMRST(model, deck);

W = schedule.control(1).W;

% Solve base case

state = standaloneSolveAD(state0, model, 1*year, 'W', W);

Solving timestep 1/1: -> 1 Year

*** Simulation complete. Solved 1 control steps in 1 Second, 782 Milliseconds ***

Go through the different cases and store the diagnostics output¶

There are 100 additional realizatiosn included, for a total of 101 different realizations. We compute pressure solutions for all realizations and compute diagnostics, including the F-Phi curve. We also compute the averaged injector and producer tracers, in order to assess the uncertainty in sweep and drainage if all the realizations are equiprobable.

n = 100;

D_all = cell(n + 1, 1);

rock_all = cell(n + 1, 1);

rock_best = rock;

% Compute base case

D = computeTOFandTracer(state, G, rock, 'wells', W);

rock_all{1} = rock;

D_all{1} = D;

[F, Phi] = deal(zeros(G.cells.num + 1, n+1));

[F(:, 1), Phi(:, 1)] = computeFandPhi(poreVolume(G,rock), D.tof);

ptracer = D.ptracer;

itracer = D.itracer;

t = 0;

hold on

for i = 1:n

% Compute for all realizations

fprintf('%d of %d\n', i, n);

deck = getDeckEGG('realization', i);

rock = initEclipseRock(deck);

rock = compressRock(rock, G.cells.indexMap);

model = PressureOilWaterModel(G, rock, fluid);

state = standaloneSolveAD(state0, model, 1*year, 'W', W);

% Compute diagnostics

tic();

D = computeTOFandTracer(state, G, rock, 'wells', W);

t = t + toc();

[F(:, i+1), Phi(:, i+1)] = computeFandPhi(poreVolume(G,rock), D.tof);

ptracer = ptracer + D.ptracer;

itracer = itracer + D.itracer;

rock_all{i+1} = rock;

D_all{i+1} = D;

end

% Compute averaged injector and producer partitions over all realizations

ptracer = ptracer./(n+1);

itracer = itracer./(n+1);

[val,ppart] = max(ptracer,[],2);

ppart(val==0) = 0;

[val,ipart] = max(itracer,[],2);

ipart(val==0) = 0;

1 of 100

Solving timestep 1/1: -> 1 Year

*** Simulation complete. Solved 1 control steps in 1 Second, 342 Milliseconds ***

2 of 100

Solving timestep 1/1: -> 1 Year

*** Simulation complete. Solved 1 control steps in 1 Second, 292 Milliseconds ***

3 of 100

Solving timestep 1/1: -> 1 Year

...

Plot the different F-Phi diagrams¶

We plot the base case in red, and all others in light gray. We observe that the base case is worse than the average, as the deviation from a piston-like displacement is large.

figure; hold on

plot(F(:, 2:end), Phi(:, 2:end), 'color', [0.3, 0.3, 0.3])

plot(F(:, 1), Phi(:, 1), 'r', 'linewidth', 2)

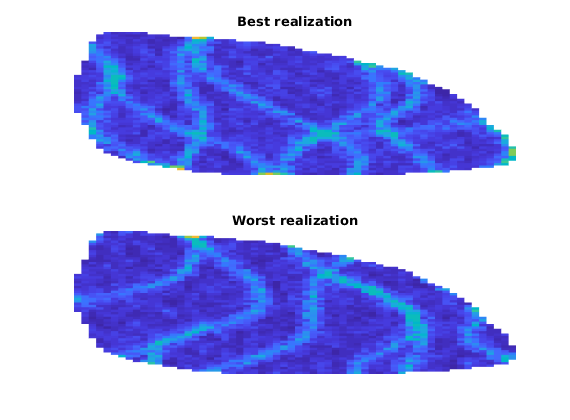

Iterate over all¶

L = zeros(n+1, 1);

for i = 1:n+1

L(i) = computeLorenz(F(:, i), Phi(:, i));

end

[mv, mix] = min(L);

[Mv, Mix] = max(L);

fprintf('Best case is case #%d with L_c = %1.4f\n', mix, mv);

fprintf('Worst case is case #%d with L_c = %1.4f\n', Mix, Mv);

clf;

subplot(2, 1, 1)

plotCellData(G, rock_all{mix}.perm(:, 1), 'EdgeColor', 'none')

axis tight off

title('Best realization')

subplot(2, 1, 2)

plotCellData(G, rock_all{Mix}.perm(:, 1), 'EdgeColor', 'none')

axis tight off

title('Worst realization')

Best case is case #16 with L_c = 0.2657

Worst case is case #99 with L_c = 0.4118

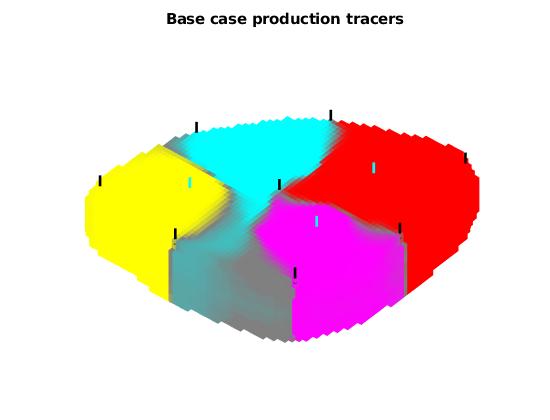

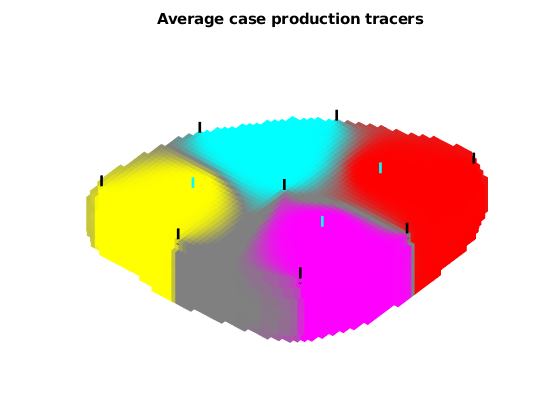

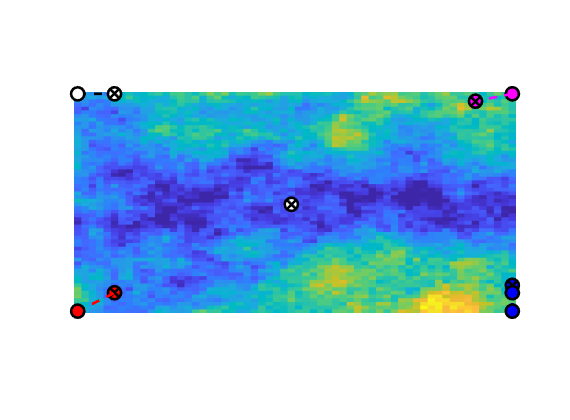

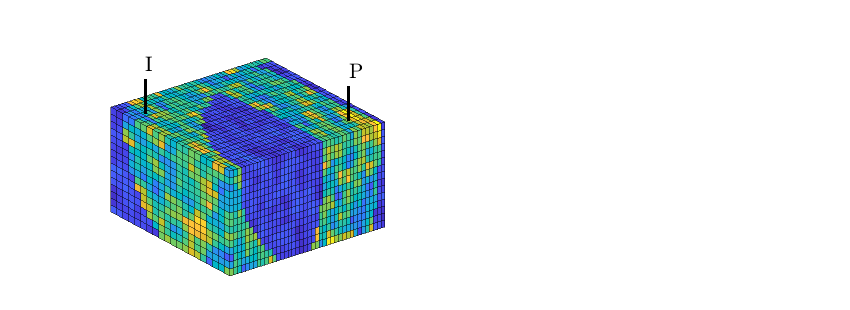

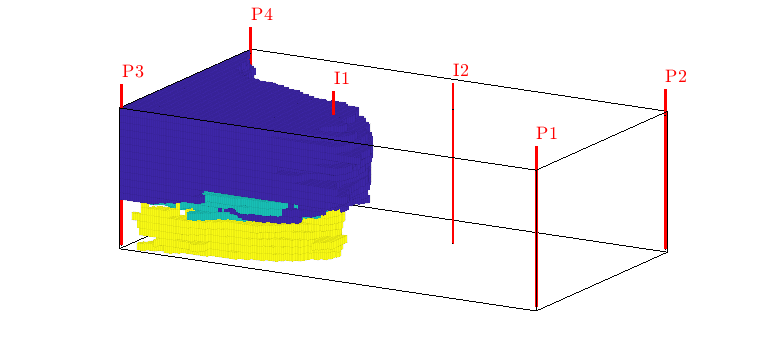

Plot the producer tracer concentrations¶

We plot both the base case, and the averaged case where the tracer value is equal to the average over all realizations. The uncertain regions that change between different wells over the ensamble are colored in gray.

wsign = [W.sign];

figure;

plotTracerBlend(G, D.ppart, max(D.ptracer, [], 2))

title('Base case production tracers')

view(-50, 70);

axis tight off

plotWell(G, W(wsign > 0), 'fontsize', 0, 'color', 'k')

plotWell(G, W(wsign < 0), 'fontsize', 0, 'color', 'c')

figure;

plotTracerBlend(G, ppart, max(ptracer, [], 2))

title('Average case production tracers');

view(-50, 70);

axis tight off

plotWell(G, W(wsign > 0), 'fontsize', 0, 'color', 'k')

plotWell(G, W(wsign < 0), 'fontsize', 0, 'color', 'c')

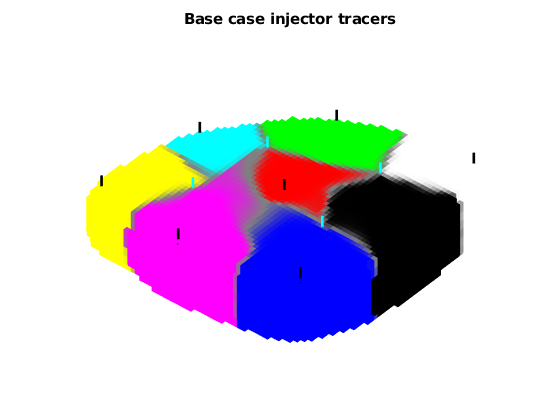

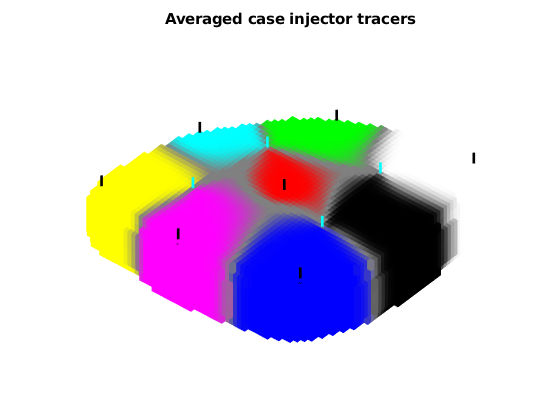

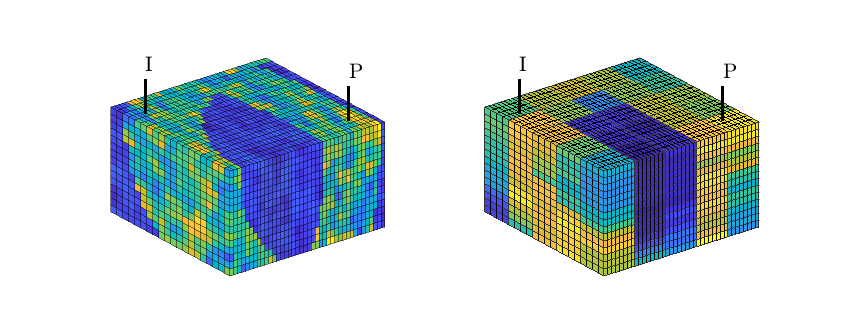

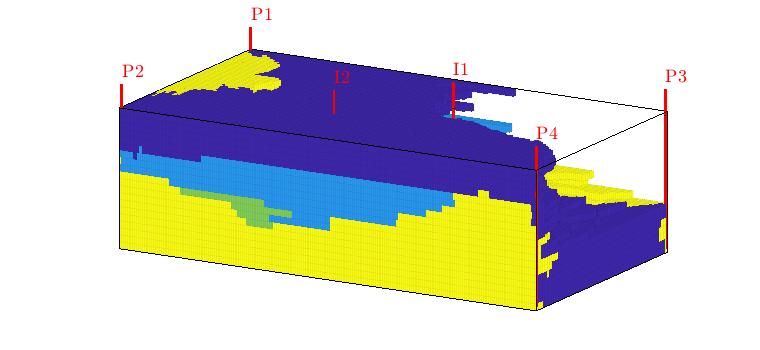

Plot injector tracers¶

figure;

plotTracerBlend(G, D.ipart, max(D.itracer, [], 2))

title('Base case injector tracers');

view(-50, 70);

axis tight off

plotWell(G, W(wsign > 0), 'fontsize', 0, 'color', 'k')

plotWell(G, W(wsign < 0), 'fontsize', 0, 'color', 'c')

figure;

plotTracerBlend(G, ipart, max(itracer, [], 2))

title('Averaged case injector tracers');

view(-50, 70);

axis tight off

plotWell(G, W(wsign > 0), 'fontsize', 0, 'color', 'k')

plotWell(G, W(wsign < 0), 'fontsize', 0, 'color', 'c')

Flow Pattern and Dynamic Heterogeneity for 2D Five-Spot Problem¶

Generated from diagnostFlowPatterns.m

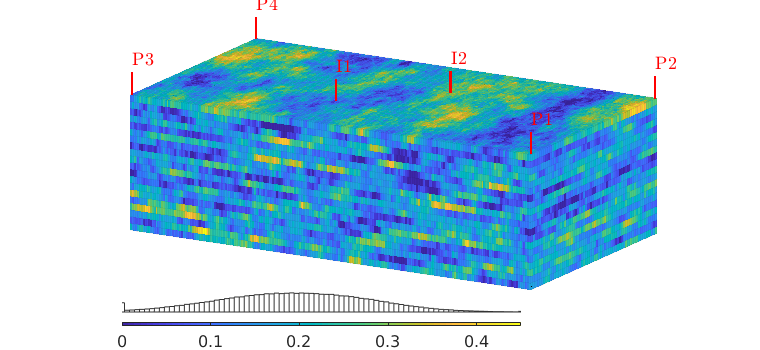

In this example we will demonstrate how we can use time-of-flight and stationary tracer distribution computed using a standard finite-volume method to visualize flow patterns and compute three different measures for dynamic heterogeneity:

mrstModule add diagnostics spe10 incomp

Set up and solve flow problem¶

As our example, we consider a standard five spot with heterogeneity sampled from Model 2 of the 10th SPE Comparative Solution Project.

[G, W, rock] = getSPE10setup(25);

rock.poro = max(rock.poro, 1e-4);

fluid = initSingleFluid('mu', 1*centi*poise, 'rho', 1014*kilogram/meter^3);

rS = initState(G, W, 0);

T = computeTrans(G, rock);

rS = incompTPFA(rS, G, T, fluid, 'wells', W);

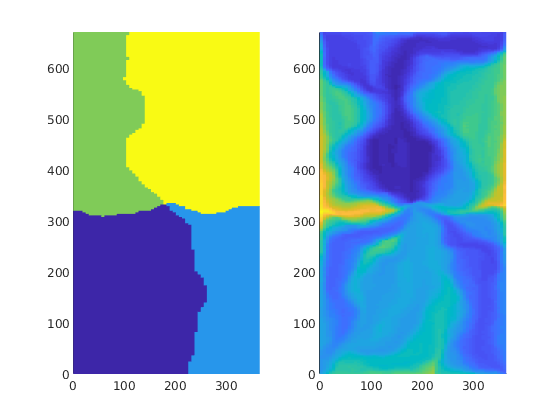

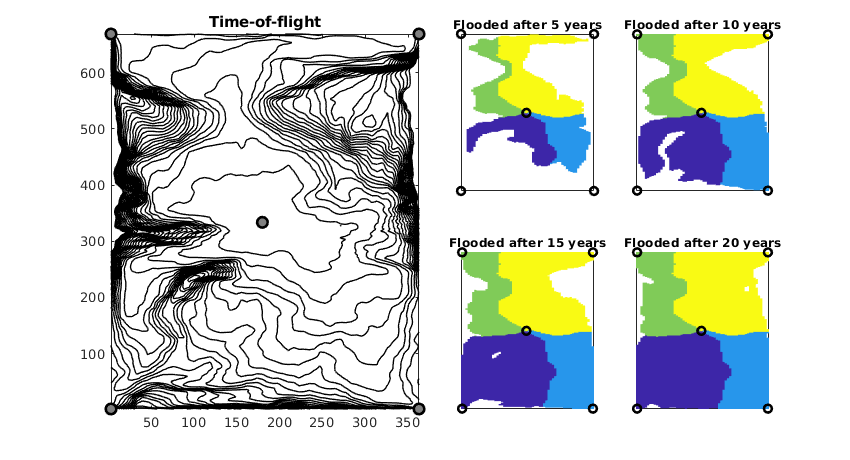

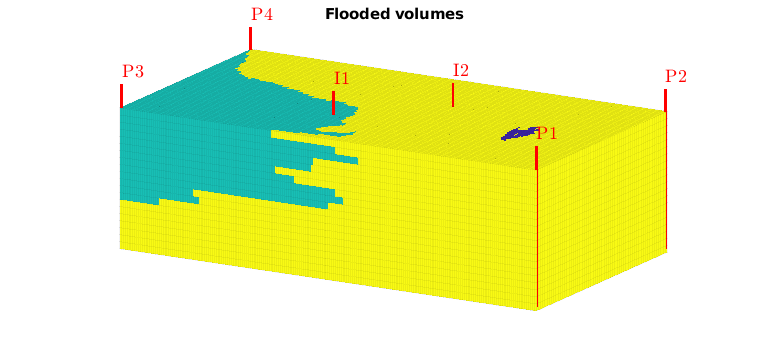

Compute and display time-of-flight and tracer partitioning¶

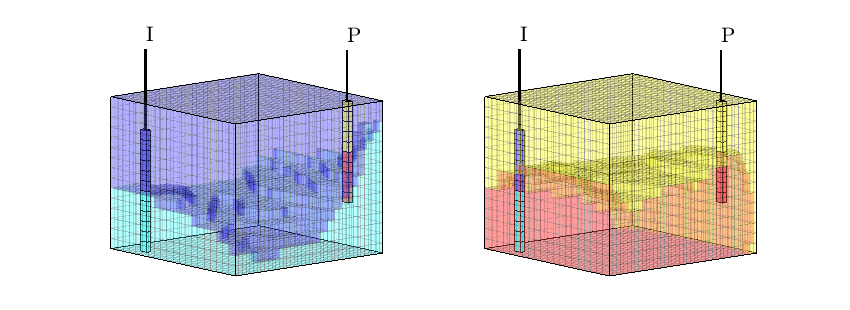

First we compute time-of-flight which is the travel time from an injector to a given point in the reservoir, and stationary distribution of tracers injected continuously from each injetion well. From the latter, we can easily compute the volume flooded by each injector. Reversing the velocity field, we can cmopute the reverse time-of-flight (the travel time from an arbitrary point to the nearest producer) and the drainage volumes of each producer.

pargs = {'EdgeColor','none'};

D = computeTOFandTracer(rS, G, rock, 'wells', W);

subplot(1,2,1); plotCellData(G,D.ppart,pargs{:}); axis equal tight

subplot(1,2,2); plotCellData(G,log10(sum(D.tof,2)),pargs{:}); axis equal tight

Threshold the tracer regions using time-of-flight to show the development of flooded regions

figure('Position',[600 360 840 460]);

subplot(2,4,[1 2 5 6]);

hold on

contour(reshape(G.cells.centroids(:,1),G.cartDims), ...

reshape(G.cells.centroids(:,2),G.cartDims), ...

reshape(D.tof(:,1)/year,G.cartDims),1:25,...

'LineWidth',1,'Color','k');

xw = G.cells.centroids(vertcat(W.cells),:);

plot(xw(:,1), xw(:,2), 'ok',...

'LineWidth',2,'MarkerSize',8,'MarkerFaceColor',[.5 .5 .5])

hold off, box on, axis tight, cpos = [3 4 7 8];

title('Time-of-flight');

for i=1:4

subplot(2,4,cpos(i)); cla

plotCellData(G,D.ppart, D.tof(:,1)<5*i*year,pargs{:});

hold on, plot(xw(:,1),xw(:,2),'ok','LineWidth',2)

title(['Flooded after ' num2str(i*5) ' years']);

axis tight, box on

set(gca,'XTick',[],'YTick',[]);

end

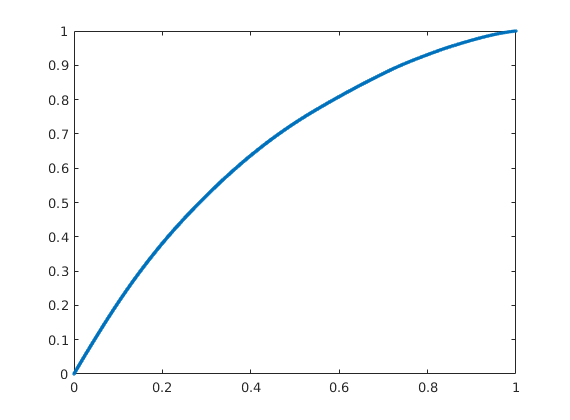

Compute and display flow-capacity/storage-capacity diagram¶

Making an analogue to 1D displacement theory, the F-Phi curve is the equivalent to a plot of the fractional flow versus saturation.

[F,Phi] = computeFandPhi(poreVolume(G,rock),D.tof);

figure, plot(Phi,F,'.');

Compute the Lorenz coefficient¶

The Lorenz coefficient is a popular measure of heterogeneity. It is equal to twice the area under the curve and above the F=Phi line. It varies between 0 (homogeneous displacement) to 1 (infinitely heterogeneous displacement).

fprintf(1, 'Lorenz coefficient: %f\n', computeLorenz(F,Phi));

Lorenz coefficient: 0.317012

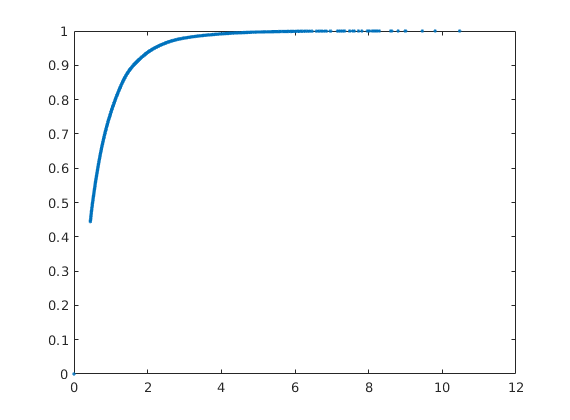

Compute and display sweep efficiency versus dimensionless time¶

Analogue: 1D displacement using the F-Phi curve as a flux function

[Ev,tD] = computeSweep(F,Phi);

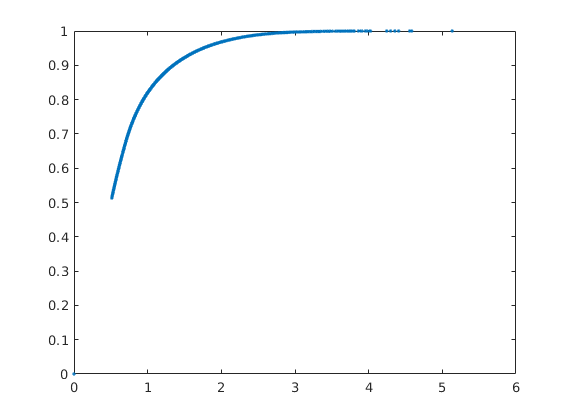

figure, plot(tD,Ev,'.');

Copyright notice¶

<html>

% <p><font size="-1

Introduction to Flow Diagnostics¶

Generated from diagnostIntro.m

In this tutorial, we will introduce you to the basic ideas of flow diagnostics. The basic quantitites in flow diagnostics are time-of-flight and numerical tracer partitions, which in turn can be used to compute volumetric connections, flux allocation between wells, and measures of dynamic heterogeneity, or just be used to indicate how displacement fronts will propagate in the reservoir, given a steady flow field. Flow diagnostics has often been associated with streamline methods. Herein, however, we will compute the same kind of quantities and measures using the first-order, finite-volume discretization which is used in MRST and in most commercial reservoir simulators. This means that whereas the computed flow diagnostics may not necessarily be an accurate representation of the corresponding continuous problem, it will represent the volumetric connections and dynamic heterogeneity, as seen by a multiphase simulator. Suggested reading:

mrstModule add diagnostics incomp streamlines;

% NB: In this example, we use the |parula| colormap. If this is not yet

% available in your MATLAB, you can e.g., replace all occurences of

% |parula| with |jet|

pargs = {'EdgeColor','none','FaceAlpha',.6};

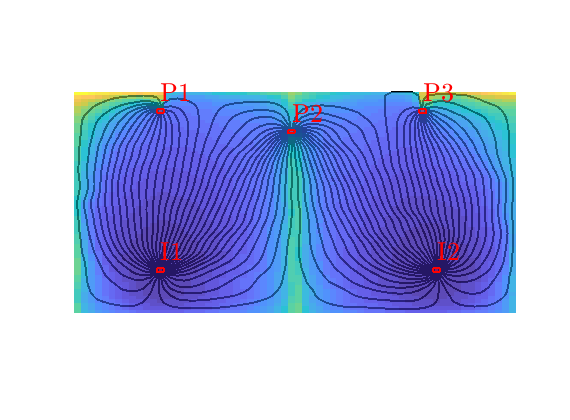

Set up and solve flow problem¶

To illustrate the various concepts, we use a rectangular reservoir with five wells, two injectors an five producers

% Grid

[nx,ny] = deal(64);

G = cartGrid([nx,ny,1],[500,250,10]);

G = computeGeometry(G);

% Petrophysical data

p = gaussianField(G.cartDims(1:2), [0.2 0.4], [11 3], 2.5);

K = p.^3.*(1.5e-5)^2./(0.81*72*(1-p).^2);

rock = makeRock(G, K(:), p(:));

hT = computeTrans(G, rock);

pv = sum(poreVolume(G,rock));

% Fluid model

gravity reset off

fluid = initSingleFluid('mu', 1*centi*poise, 'rho', 1014*kilogram/meter^3);

% Wells

n = 12;

W = addWell([], G, rock, nx*n+n+1, ...

'Type', 'rate', 'Comp_i', 1, 'name', 'I1', 'Val', pv/2);

W = addWell(W, G, rock, nx*n+n+1+nx-2*n, ...

'Type','rate', 'Comp_i', 1, 'name', 'I2', 'Val', pv/2);

W = addWell(W, G, rock, round(G.cells.num-(n/2-.5)*nx-.3*nx), ...

'Type','rate', 'Comp_i', 0, 'name', 'P1', 'Val', -pv/4);

W = addWell(W, G, rock, G.cells.num-(n-.5)*nx, ...

'Type','rate', 'Comp_i', 0, 'name', 'P2', 'Val', -pv/2);

W = addWell(W, G, rock, round(G.cells.num-(n/2-.5)*nx+.3*nx), ...

'Type','rate', 'Comp_i', 0, 'name', 'P3', 'Val', -pv/4);

% Initial reservoir state

state = initState(G, W, 0.0, 1.0);

Compute basic quantities¶

To compute the basic quantities, we need a flow field, which we obtain by solving a single-phase flow problem. Using this flow field, we can compute time-of-flight and numerical tracer partitions. For comparison, we will also tracer streamlines in the same flow field.

state = incompTPFA(state, G, hT, fluid, 'wells', W);

D = computeTOFandTracer(state, G, rock, 'wells', W);

% Trace streamlines

seed = (nx*ny/2 + (1:nx)).';

Sf = pollock(G, state, seed, 'substeps', 1);

Sb = pollock(G, state, seed, 'substeps', 1, 'reverse', true);

Warning: Well rates and flux bc must sum up to 0

when there are no bhp constrained wells or pressure bc.Results may not be

reliable.

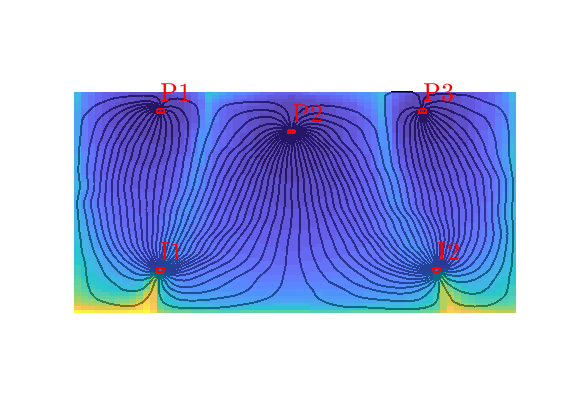

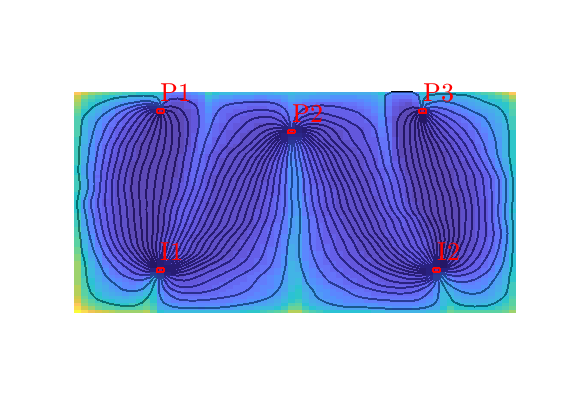

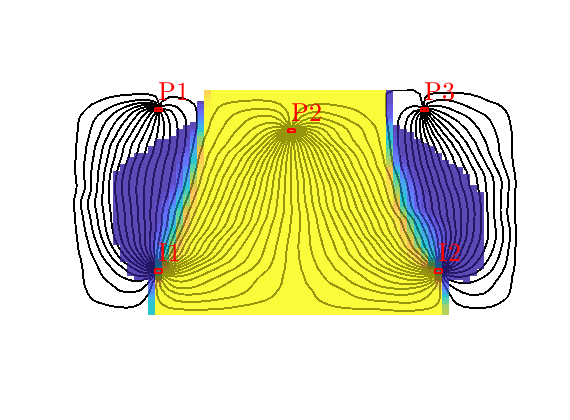

Forward time-of-flight¶

The time-of-flight gives the time it takes a neutral particle to travel from the nearest inflow boundary (e.g., an injection well) and to a given point in the reservoir. Here, we do not compute this quantity pointwise, but rather in an volume-averaged manner over each grid cell

clf

hf=streamline(Sf);

hb=streamline(Sb);

plotGrid(G,vertcat(W.cells),'FaceColor','none','EdgeColor','r','LineWidth',1.5);

plotWell(G,W,'FontSize',20);

set([hf; hb],'Color','w','LineWidth',1.5);

hd=plotCellData(G,D.tof(:,1),pargs{:});

colormap(parula(32));

axis equal off;

Backward time-of-flight¶

Backward time-of-flight is defined analogously, as the name suggests, by tracing particles backward along the flow field from the nearest outlet (e.g., a production well). For a given point, this quantity thus represents the time it will take a neutral particle to reach the outlet.

delete(hd);

hd=plotCellData(G,D.tof(:,2),pargs{:});

Residence time¶

The residence time is defined as the sum of the forward and backward time-of-flight and gives the total travel time from inlet to outlet. This quantity can be used to distinguish high-flow zones, which have small residence time, from low-flow and stagnation zones, which have high residence times.

delete(hd);

hd=plotCellData(G,sum(D.tof,2),pargs{:});

Tracer from I1¶

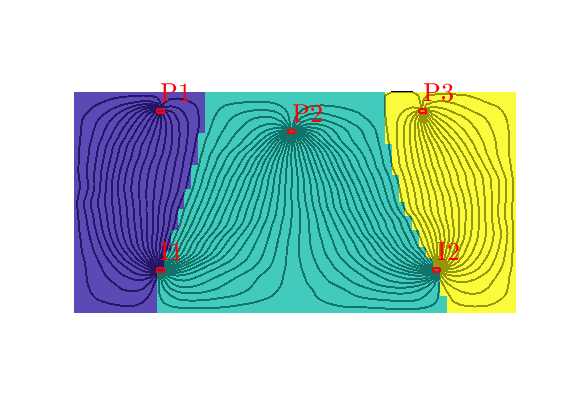

Numerical tracer partitions can be thought of as an imaginary paiting experiment, in which we inject a massless, nondiffusive ink of a unique color at each fluid source. At time infinity, each point in the reservoir must then have been colored. If a point receives more than one tracer, the tracer concentrations represent the fractional flow of past each points. The result is a volumetric partition of unity for the reservoir. To illustrate, let us look at the tracer concentration of injector I1, which is one in all parts of the reservoir except near the flow divide, where cells are affected by flow from both injectors.

delete(hd);

t = D.itracer(:,1);

hd = plotCellData(G, t, t>1e-6, pargs{:});

Flooded regions¶

Using this injection tracer, we can define the flooded regions. Each inejctor will influence all cells having a positive tracer concentration. In many cases, however, it is interesting to determine the injector that influences the most. In MRST, this is done by a simple majority vote over all tracers. In lack of a better name, this will be referred to as ‘flood regions’

delete(hd);

hd = plotCellData(G,D.ipart,pargs{:});

Tracer from P2¶

By reversing the flow field, we can compute a similar partition of unity associated with the producers, here illustrated for P2, In the figure, we see that P2 has a region in the middle of the domain that it drains all by itself, whereas the regions to the east and west are also drained by P3 and P1

delete(hd);

t = D.ptracer(:,2);

hd = plotCellData(G, t, t>1e-6, pargs{:});

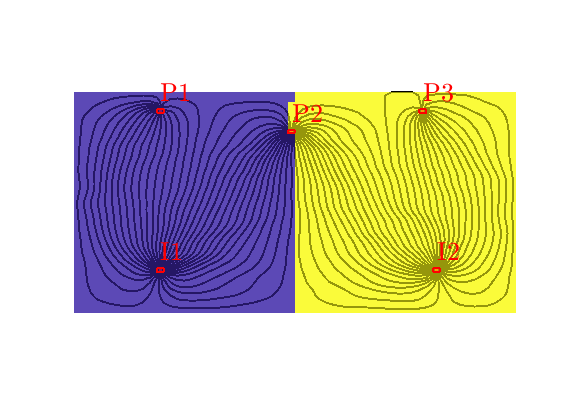

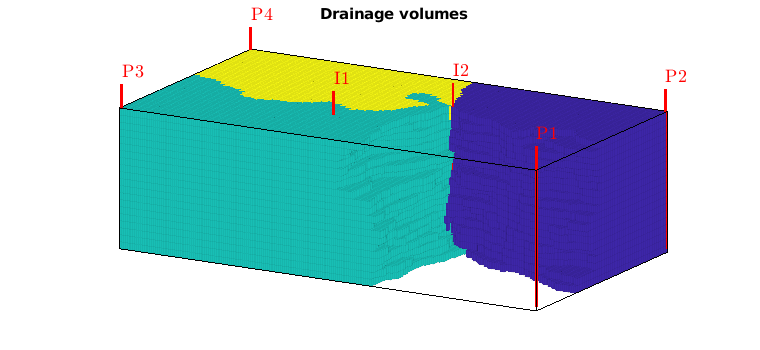

Drainage regions¶

Like we associated flood regions with injectors, we can associate drainage regions with producers, using a simple majority vote over all tracer concentrations

delete(hd);

hd = plotCellData(G,D.ppart,pargs{:});

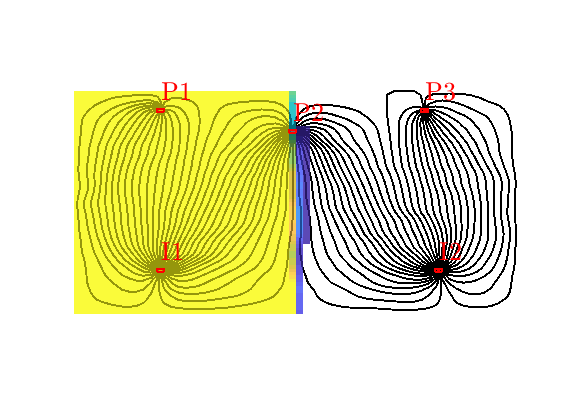

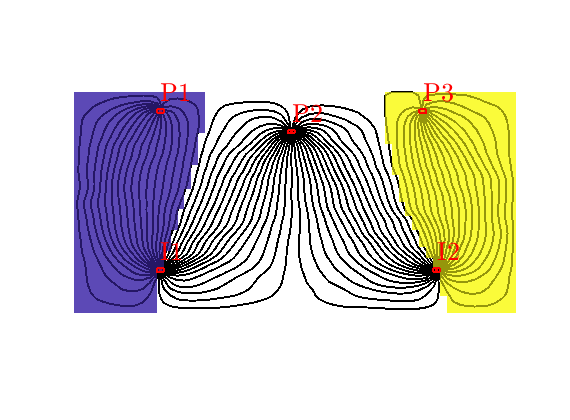

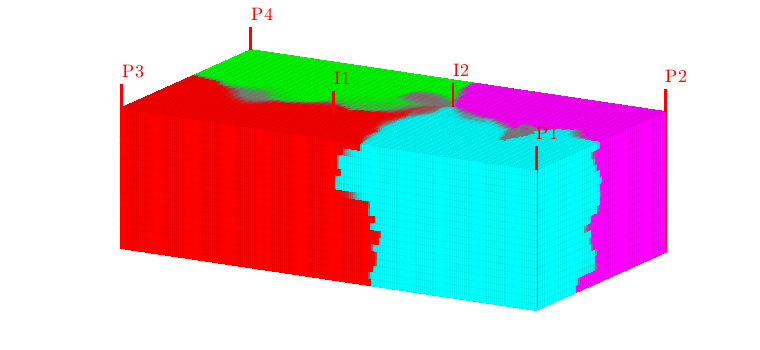

Well regions: I1<->P1, I2<->P3¶

By combining the drainage and flood regions, we can get regions that are affected by a single injector-producer pair

delete(hd);

hd = plotCellData(G,D.ipart, D.ppart~=2, pargs{:});

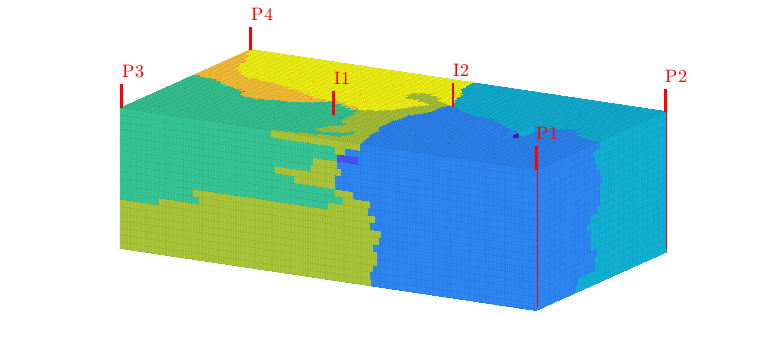

Compute time-of-flights inside each well region¶

If a cell is affected by more than one injector (or producer), the volume averaged time-of-flight can be very inaccurate as a pointwise measure if the travel times from the two injectors are very different. To amend this, we can compute time of flight for each well

T = computeTimeOfFlight(state, G, rock, 'wells', W, ...

'tracer',{W(D.inj).cells},'computeWellTOFs', true);

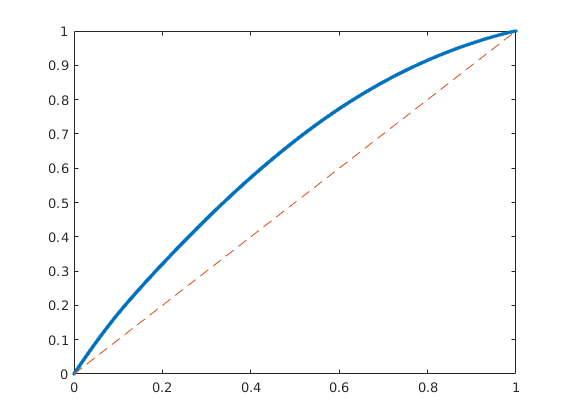

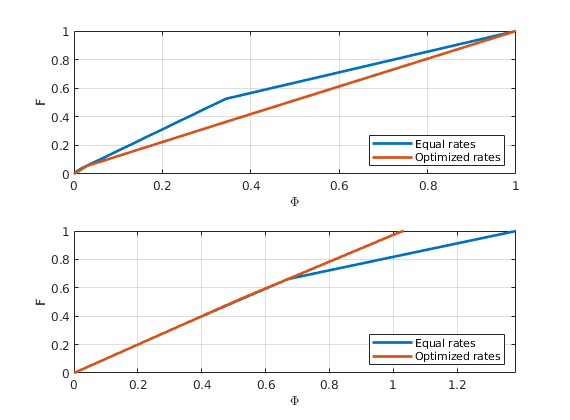

F-Phi diagram¶

To define a measure of dynamic heterogeneity, we can think of the reservoir as a bundle of non-coummunicating volumetric flow paths (streamtubes) that each has a volume, a flow rate, and a residence time. For a given time, the storage capacity Phi, is the fraction of flow paths in which fluids have reached the outlet, whereas F represent the corresponding fractional flow. Both are monotone functions of residence time, and by plotting F versus Phi, we can get a visual picture of the dynamic heterogeneity of the problem. In a completely homogeneous displacement, all flowpaths will break through at the same time and hence F(Phi) is a straight line from (0,0) to (1,1). In a heterogeneous displacement, F(Phi) will be a concave function in which the steep initial slope corresponds to high-flow regions giving early breakthrough and, whereas the flat trailing tail corresponds to low-flow and stagnant regions that would only break through after very long time

[F,Phi] = computeFandPhi(poreVolume(G,rock), D.tof);

clf, plot(Phi,F,'.',[0 1],[0 1],'--');

Lorenz coefficient¶

The further the F(Phi) curve is from a straight line, the larger the difference between fast and slow flow paths. The Lorenz coefficient measures the dynamic heterogeneity as two times the area between F(Phi) and the straight line F=Phi.

computeLorenz(F,Phi)

ans =

0.2437

Sweep effciency diagram¶

We can also define measures of sweep efficiency that tell how effective injected fluids are being used. The volumetric sweep efficiency Ev is defined as the ratio of the volume that has been contacted by the displacing fluid at time t and the volume contacted at infinite time. This quantity is usually related to dimensionless time td=dPhi/dF

[Ev,tD] = computeSweep(F,Phi);

clf, plot(tD,Ev,'.');

Copyright notice¶

<html>

% <p><font size="-1

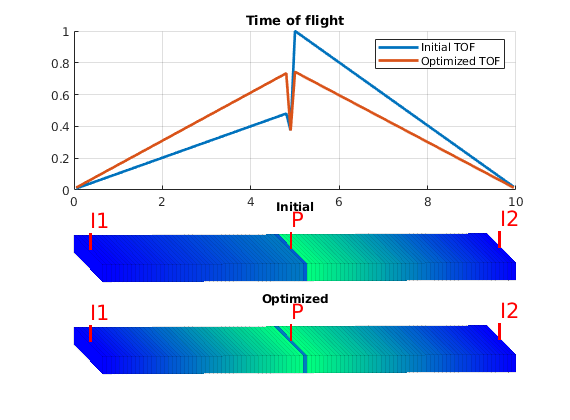

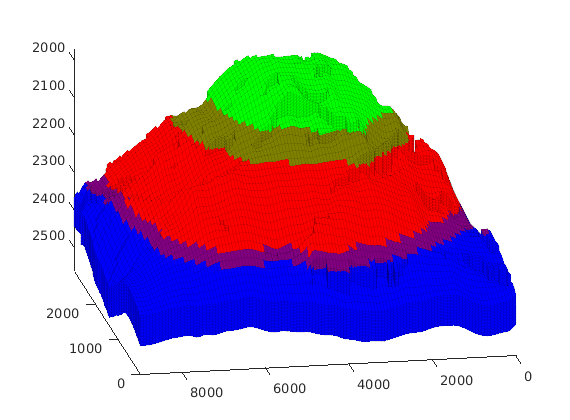

Optimizing Well Placement and Rates¶

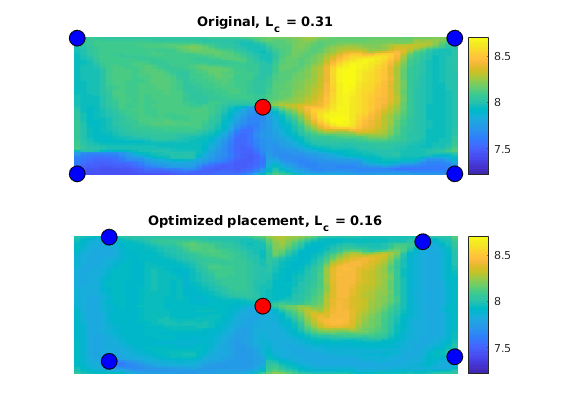

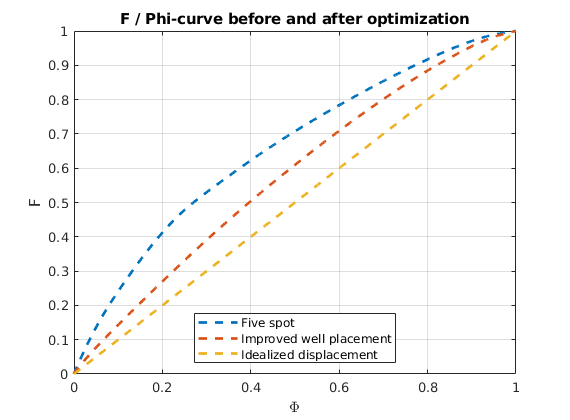

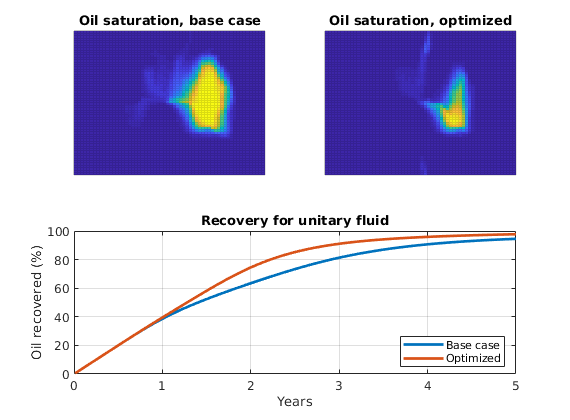

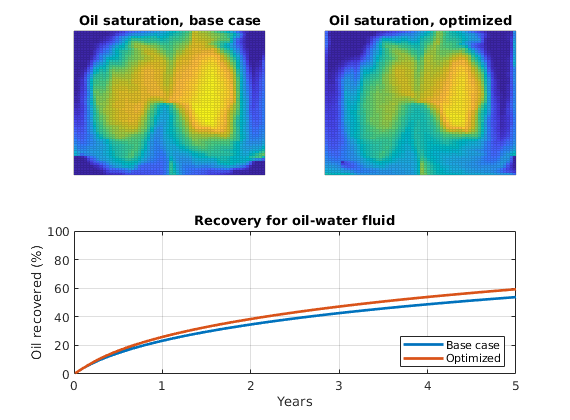

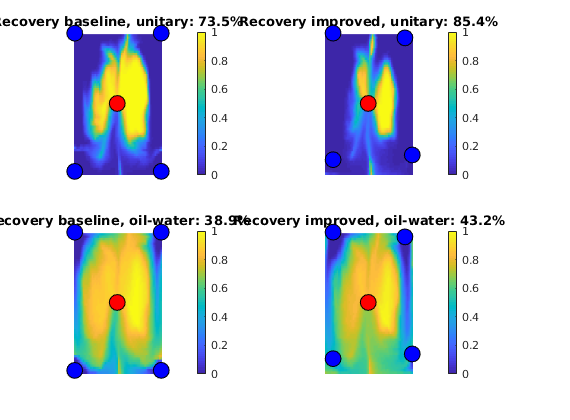

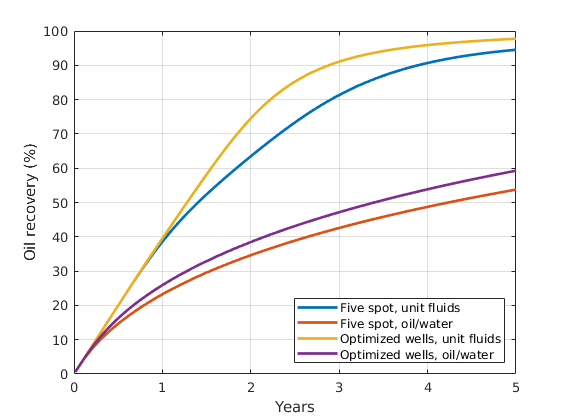

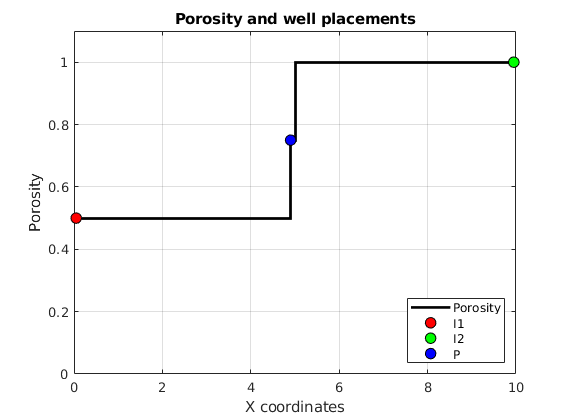

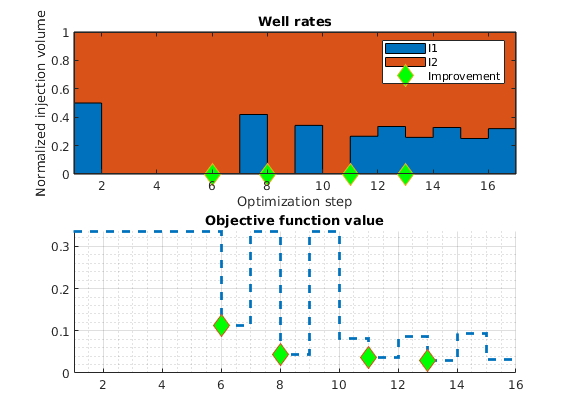

Generated from diagnostOptimWellPlacement.m

This tutorial shows algorithms for optimized well placement and/or optimization of injection rates for regular Cartesian grids. The script optimizes the wells and then runs incompressible simulations with different fluid properties to evaluate the validity of the optimization. Depending on the configuration, this example may take some time to run. Different options can be changed for different results. The default is to optimize the placement of the wells, but not their rates.

mrstModule add ad-core ad-props diagnostics spe10 incomp

close all

Parameters that determine the setup¶

fiveSpotWells = true; % If false: all injectors near the middle

optimizeSubsteps = true; % If false: rates not optimized for each step

optimizePlacement = true; % If false: only iinjection rates optimized

wradius = 5; % Search radius for well movement. Larger

% values may give faster convergence

rocktype = 'tarbert'; % Values: 'tarbert', 'ness', 'uniform'

[Nx,Ny,Nz] = deal(60,60,1); % Grid size. SPE: Nx<=60, Ny<=220

switch lower(rocktype)

case 'ness',

[offset, uniformRock] = deal(65, false);

case 'tarbert',

[offset, uniformRock] = deal(0 , false);

case 'uniform',

[offset, uniformRock] = deal(0 , true );

[optimizeSubsteps,fiveSpotWells,wradius] = deal(false,false,1);

otherwise

error('Unknown setup!')

end

Set up reservoir and fluid properties¶

This code is a bit verbose because it allows for different options in the same example.

% Grid setup

G = cartGrid([Nx, Ny, Nz], [Nx, Ny, Nz].*[20, 10, 2].*ft);

G = computeGeometry(G);

% Rock setup

if uniformRock

rock.poro = repmat(0.3, [G.cells.num, 1]);

rock.perm = repmat(100*milli*darcy, [G.cells.num, 1]);

else

rock = getSPE10rock(1:Nx, 1:Ny, (1:Nz) + offset);

rock.poro(rock.poro < 0.01) = 0.01;

end

pv = poreVolume(G, rock);

T = computeTrans(G, rock);

% State

% Fluid

fluid_ad = initSimpleADIFluid('mu', [1,1,1].*centi*poise, 'n', [1,1,1]);

% Build discrete operators

ops = setupOperatorsTPFA(G, rock);

Set up wells¶

The wells are set to inject one pore volume per injector over a total period of ten years. We use the array targets to keep track of the wells whose rates are to be optimized. If fiveSpotWells is true, the injectors are set in the corners of the domain. Otherwise, they are positioned ten cells away from the producer.

inRate = sum(pv)/(10*year); % Initial rate

minRate = inRate/4; % Minimum allowed rate

[midx, midy] = deal(ceil(Nx/2), ceil(Ny/2)); % Midpoint: producer

addw = @(W, i, j, k) ...

verticalWell(W, G, rock, i, j, k, 'Val', inRate, 'Type', 'rate');

W = [];

for i = -1:2:1

for j = -1:2:1

if fiveSpotWells

% Set up injector in each corner

W = addw(W, Nx*(i==1) + 1*(i==-1), Ny*(j==1) + 1*(j==-1), []);

else

% Set up injectors jumbled around the producer

W = addw(W, midx - 10*i, midy - 10*j, []);

end

end

end

targets = 1:numel(W); % Indices of wells to be optimized

W = [W; verticalWell([], G, rock, midx, midy, [], ...

'Val', 0, 'Type', 'bhp', 'Name', 'P')];

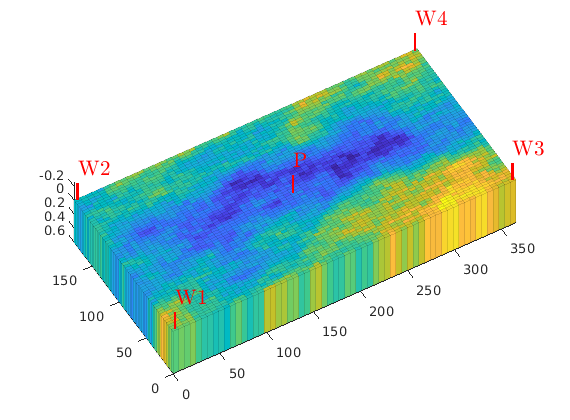

Plot the initial setup¶

clf

plotCellData(G, log10(rock.perm(:, 1)), 'EdgeAlpha', 0.125);

plotWell(G, W, 'height',.25);

axis tight, set(gca,'DataAspect',[1 1 .01]), view(-30,50)

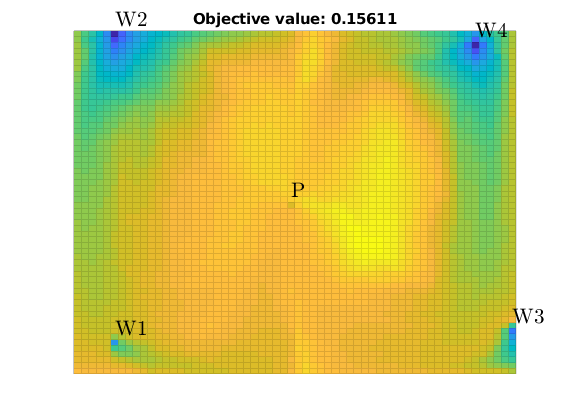

Set up objective functions and optimize¶

As objective function for the optimization, we will use the Lorenz coefficient, which means that we try to equilibrate the length of all flow paths. The optimization may take some time if both rates and placement are to be optimized.

% Objective function

objective = getObjectiveDiagnostics(G, rock, 'minlorenz');

% Handle for pressure solver

state0 = initResSol(G, 0*barsa, [0 1 0]);

solvePressure = @(W, varargin) ...

solveStationaryPressure(G, state0, ops, W, fluid_ad, pv, T, ...

'objective', objective, varargin{:});

% Solve pressure and display objective value

[state, D, grad0] = solvePressure(W); grad0.objective.val

% Optimize

if optimizePlacement

[W_opt, wellHistory, optHistory] = ...

optimizeWellPlacementDiagnostics(G, W, rock, objective, targets, ...