Offshore Power Electronics

2000 A Power cycling tester

The 2000 A power cycling tester has been a central part of the research project

It was constructed and commissioned by Technical University of Chemnitz in 2012. As part of joint research collaboration, the equipment was transferred to SINTEF Energy Research in Trondheim. The following figures show pictures of the setup and simplified schematics.

The test rig includes the following main components:

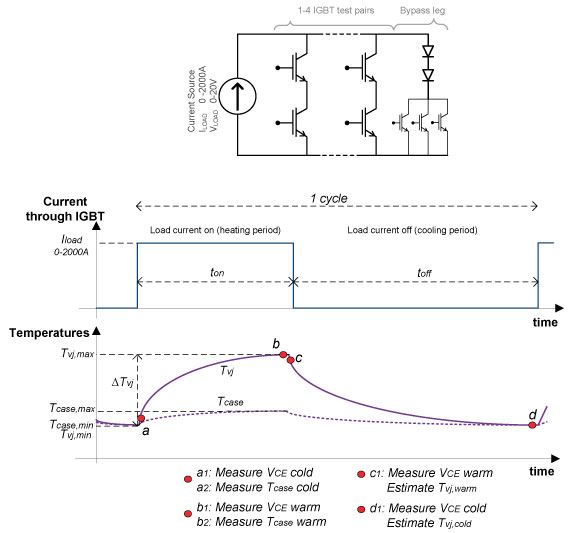

- Load current source: equipped with fast and accurate control in the range 0-2000 A/0-20 V. Response time of the controller lies in the range of 1 ms.

- Devices under test (DUTs): Up to 8 IGBT test objects placed in four bridge legs

- Bypass leg: Used to circulate the load current for additional time (giving extra cooling time for all DUTs).

- Heat exchanger: 20 kW cooling capability for removing the IGBT power losses. Based on de-ionized water. Up to 12 kW heating capability can be utilized if needed.

- Control and monitoring cabinet: Logging of case temperatures and IGBT conduction voltages. Control of IGBT turn-on / turn-off. Various safety features. NI cRIO-based