Offshore Power Electronics

Reliable IGBTs

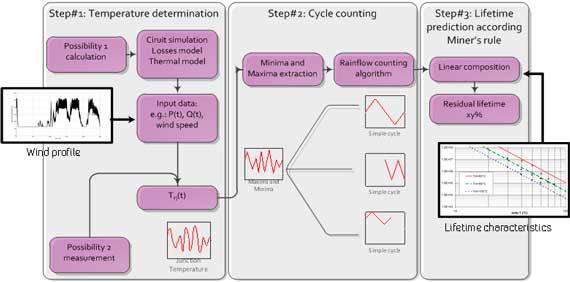

Power and temperature cycling of the power semiconductors (IGBTs) in wind power converters affects the reliability and lifetime of the components. This has been demonstrated in the OPE project by transient simulations where detailed models for the electric circuits and the thermal circuits are combined, and where data for the component electrical characteristics (switching losses and conducting losses) and thermal characteristics has been used.

The main focus for the reliability research has been on providing tools, methods and data for calculating reliability of power semiconductors (IGBTs) in wind turbine converters. The special power semiconductor Power Cycling Tester has been in operation for investigating reliability and failure mechanisms for large press-pack IGBTs. These types of IGBTs are pretty unexplored as to failure mechanisms. The results from experimental work performed by the PCT have been correlated with the theoretical work on stress modeling of IGBTs, performed by the project PhD student. The experimental work as well as the analytical work has produced very interesting findings that are also proposed to be continued in a possible new project. The project has also provided new ideas on how to use information about IGBT reliability to predict operational dependent rest life-time for the devices.

A common journal paper from SINTEF and TU Chemnitz with results from the IGBT reliability work has been submitted to Microelectronics Reliability.

Summary of achievements:

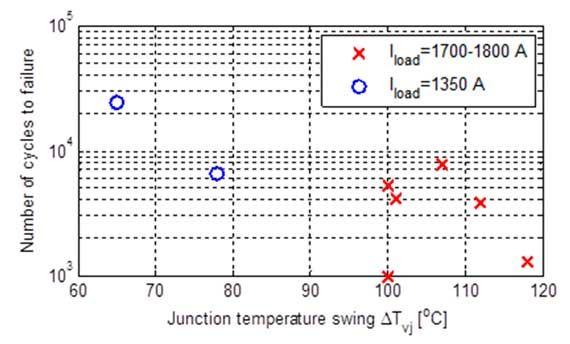

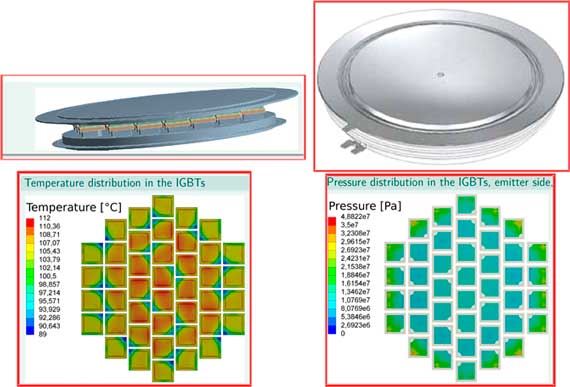

The IGBT Power Cycling Tester (PCT) has been in operation for investigating reliability and failure mechanisms for large press-pack IGBTs. These types of IGBTs are pretty unexplored as to failure mechanisms. The results from the work are summarized in a journal paper submitted to Microelectronics Reliability in October 2014. The number of cycles of failure as a function of the thermal swing is shown in the figure below. Since the number of cycles were lower than expected, a thorough post examination was conducted based on microscopy supported FEM-analysis. The work led to the proposal of two failure mechanisms previously unreported in literature, both related to uneven pressure distributeion inside the press-pack disks.

New ideas on how to predict operational dependent rest life-time for IGBTs