BIO gillnets

Biodegradable gillnets are being tested in Norway since 2016 as an attempt to reduce ghost fishing and marine litter caused by lost gillnets.

Biodegradable gillnets are being tested in Norway since 2016 as an attempt to reduce ghost fishing and marine litter caused by lost gillnets.

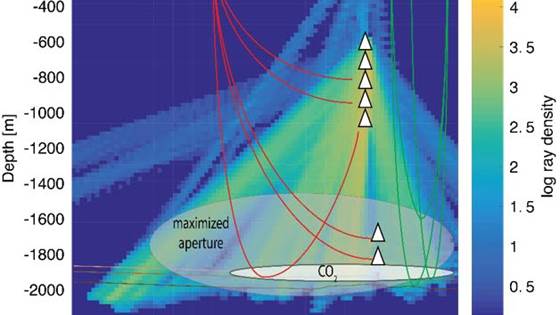

An innovative concept for time-dependent monitoring of CO2 plume expansion by combining active and passive seismic data.

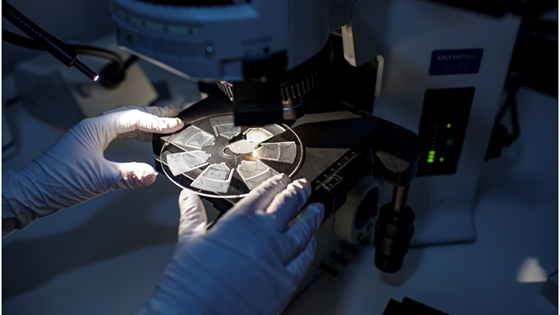

In the EU alone, around 2.5 million people are allergic to β-lactam antibiotics and this figure increases every year due to excessive drug intake. The main objective of COBIOPHAD project is the development of an integrated biophotonic device based on...

EARTH focuses on separation and procedures to improve runway and airport throughput considering wake-vortex, weather, environment and noise, while taking into account future traffic demand, aircraft capability and airport configurations.

The ERIFORE will realize the European potential to consolidate its place as a world leader in biomass based research and innovations. ERIFORE builds on a new firm alliance aiming to establish open access distributed forest bioeconomy research...

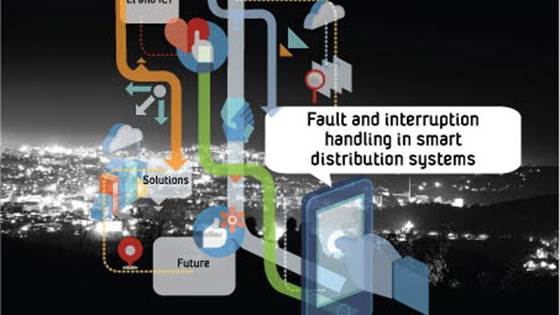

This project would investigate how smart grid technology can be utilized in the electric distribution grid to reduce interruptions in the electricity supply and socio-economic costs of interruptions.

In Flexi3D we will develop new technologies that can meet industry needs: a rapid and precise pick, place & verify solution that enables profitable future automation solutions.

Society is crucially dependent on an adequate level of security of electricity supply. This imposes requirements for the planning and operation of modern power systems.

HiPerNav will train early stage researchers (biomedical engineers and medical doctors) to become international leading experts in key areas of expertise through a novel coordinated plan of individual research projects addressing specific bottlenecks...

SINTEF possesses internationally unique laboratory facilities for multiphase flow research that have had huge benefits for the Norwegian oil industry and for the Norwegian industry cluster based on multiphase flow technology.

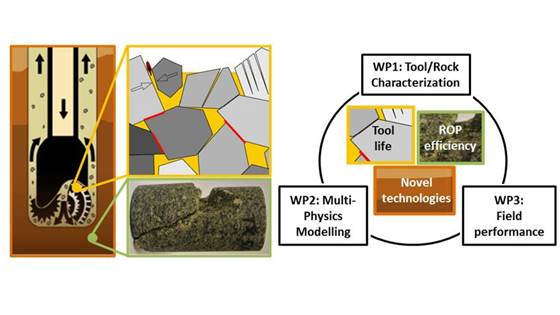

The main goal of INNO-Drill project is to extend, demonstrate, and make available a research-based technology platform to enable new and significantly more cost effective drilling tools and systems for deep geothermal wells in hard rock formations.

The MACROSEA project will target successful and predictable production of high quality biomass thereby making significant steps towards industrial macroalgae cultivation in Norway.

The marine biomasses used in Mar3Bio are brown algae and crustacean byproducts which are sources of the marine polysaccharides alginate and chitosan. These abundant but underexploited renewable biomasses have great potential for production of high...

The goal of the "Meet easy" project was to provide a complete, easy-to-use videoconferencing solution delivering high-end features such as high-quality audio and video with a wide field of view – in a compact form and at a fraction of the cost...

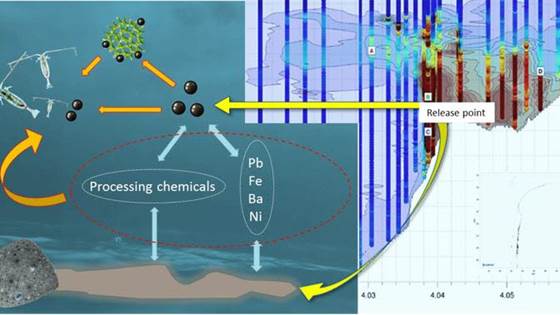

MERIT is an internally funded research project (SEP) that studies the fate and effects of subsea mine tailing disposal in Norwegian fjords

SINTEF and Institutt for Energiteknikk (IFE) have entered into agreement with seven companies on a new and exciting data collection project. The recently upgraded laboratories at Tiller and Kjeller now go directly into industrial use.

Demonstration of the next generation standardised integrated cooling and heating packages for commercial and public buildings based on environment-friendly carbon dioxide vapour compression cycles.

Enabling better collaboration between humans and decision support systems in time-critical complex domains