This lab complements the other four main labs of the Polymer and Composite Materials research group, the polymer chemistry lab, the mechanical testing lab, the processing lab and the ageing lab.

For other material characterization methods we can guide you to relevant SINTEF labs.

General description of lab facilities and equipment

The instruments are used for many different purposes:

- Material identification, including type and amount of fillers etc

- Obtaining material "fingerprints", e.g. comparing two materials or batches with methods which are sensitive to small differences in chemical or physical structure

- Troubleshooting when a product has failed

- Analyzing new or modified materials

- Analyzing effects of processing, ageing, mechanical loading etc

- Analyzing materials to improve routes for mechanical and chemical recycling of materials, as well as reuse of products

- Analyzing the processability of materials in terms of viscosity and other rheological properties of melts, solutions, gels etc

Our lab (and SINTEF labs we collaborate closely with) has equipment for the following methods:

- Microscopy etc

- Optical microscopy, IR spectroscopy/microscopy, scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), white light interferometry (WLI)

- Spectroscopy, diffraction methods etc for characterizing chemical and physical structure (bulk and surfaces):

- IR spectroscopy, scanning electron microscopy with energy dispersive X-ray spectroscopy (SEM/EDS), x-ray photoelectron spectroscopy (XPS), NMR spectroscopy, wide angle x-ray scattering (WAXS)

- Thermal and thermo-mechanical characterization (melting temperature, glass transition temperatures, oxidation induction time, crystallization kinetics, thermal expansion etc)

- Differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), dynamic mechanical-thermal analysis (DMTA), dilatometry (measuring thermal expansion/contraction), thermal conductivity

- Viscosity and other rheological parameters

- Rotational rheometry, capillary rheometry, melt flow rate (MFR) measurements

- Other properties/methods

- Density of solids, moisture content in materials, contact angle measurements (surface tension), optical properties (colour, gloss, transmission, haze etc), mechanical properties, mass spectroscopy, chromatography

Equipment

Details about some of the instruments are given below:

IR spectroscopy/microscopy

Instrument: 670/620 FTIR Imaging Microscope from Agilent

Description:

IR spectroscopy can detect chemical groups, to identify materials and e.g. analyse material modifications or chemical degradation. It can also be used to assess the physical structure, e.g. type of crystal structure, degree of crystallinity and anisotropy. This fourier transform infrared (FTIR) spectrometer has an attached microscope for characterizing the spatial distribution of components/materials, on a surface, over a cross-section or in a sample of mixed microplastics.

The instrument has a 128 x 128 focal plane array detector allowing for fast "chemical mapping" by recording multiple infrared spectra from different points on the same sample, which facilitates the study of within-sample chemical heterogeneity. The software allows to overlay the visible image with the chemical image to facilitate the identification of surface features. By using the mosaic mode surface areas of several square millimetre in size can be analysed.

Brochure with further details about the instrument

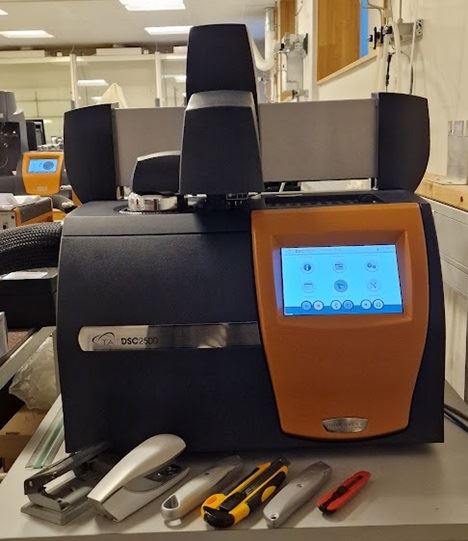

DSC – Differential scanning calorimetry

Instrument: DSC2500 from TA Instruments

Description:

Measurement of melting and crystallization temperatures, glass transition temperatures, and melting and crystallization enthalphies (crystallinity). Determination of material composition, oxidation stability, etc. An autosampler enables high throughput of samples.

Atmosphere: Dry air, oxygen or nitrogen

Temperature range: -90°C to 550°C

TGA – Thermogravimetric analysis

Instrument: TGA 55 from TA Instruments

Description:

Measurement of the change in mass of a sample as it is heated or held at constant temperature. This gives information of composition, volatiles, decomposition, residual solids contents, etc. An autosampler enables high throughput of samples.

Atmosphere: dry air or nitrogen

Temperature range: ambient to 1000 °C

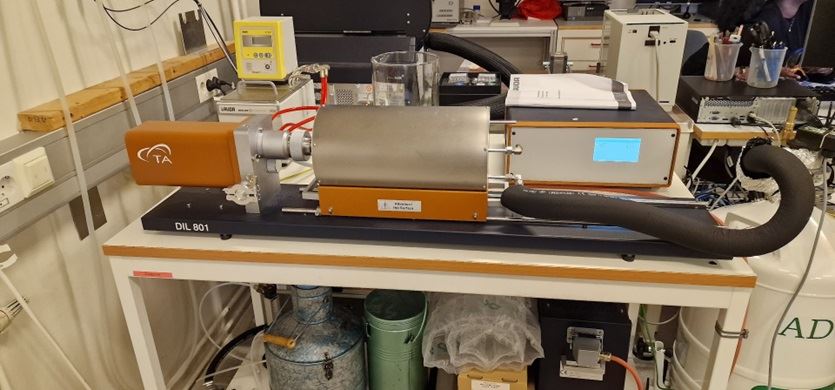

Dilatometry (thermal expansion/contraction)

Instrument: DIL 801 from TA Instruments

Description:

Measurement of linear thermal expansion of solids. i.e. how materials change dimensions when heated or cooled.

Atmosphere: Air or nitrogen

Temperature range: -160 °C to 1700 °C

Rotational rheometry

Instrument: MCR 502 from Anton Paar

Description:

This instrument can be used for measuring the viscosity of fluids (polymer melts, adhesives, coatings etc) as function of temperature and shear rate, as well as other rheological properties of fluids and solids. A range of different fixtures are available for this instrument. Viscosity is often measured to assess the chemical degradation of a material. Furthermore, oscillatoric rheological measurements of a polymer melt is a sensitive method which can provide information about a polymer material's molecular weight distribution and chain branching. The instrument can also be used to follow the curing of e.g. an epoxy material. For solids, dynamic mechanical-thermal analysis (DMTA) is a common method. DMTA is e.g. used to measure the glass transition temperature and the temperature dependence of the modulus (stiffness).

Temperature range for fluids: -40 °C to 200°C

Temperature range for solids: -120 °C to 450 °C