Introduction

Some examples of tests of plastics, rubbers and composites that are performed in this lab:

- Ageing of materials for outdoor applications (sun, rain, …)

- Microfibre release from textiles during household laundry

- Ageing of materials for use in solvent-based CO2 capture plants, e.g. exposure to amine based solvents

- Ageing of materials to be used in pipes etc for CO2 transport

- Ageing of materials to be used in pipes etc for hydrogen transport

- Ageing of materials used in thermal management systems for fuel cell electrical vehicles (FCEV) and battery electric vehicles (BEV). In this case, leakage of ions etc from the materials is also critical.

- Ageing of materials in flexible pipes used in the oil and gas industry

- Ageing of materials exposed to anhydrous ammonia at elevated and sub-zero temperatures

This lab complements the other four main labs of the Polymer and Composite Materials research group, the polymer chemistry lab, the materials characterization lab, the processing lab and the mechanical testing lab. We also collaborate with a SINTEF lab which can measure solubility and permeability, e.g. in studies of the effect of CO2 on polymer materials.

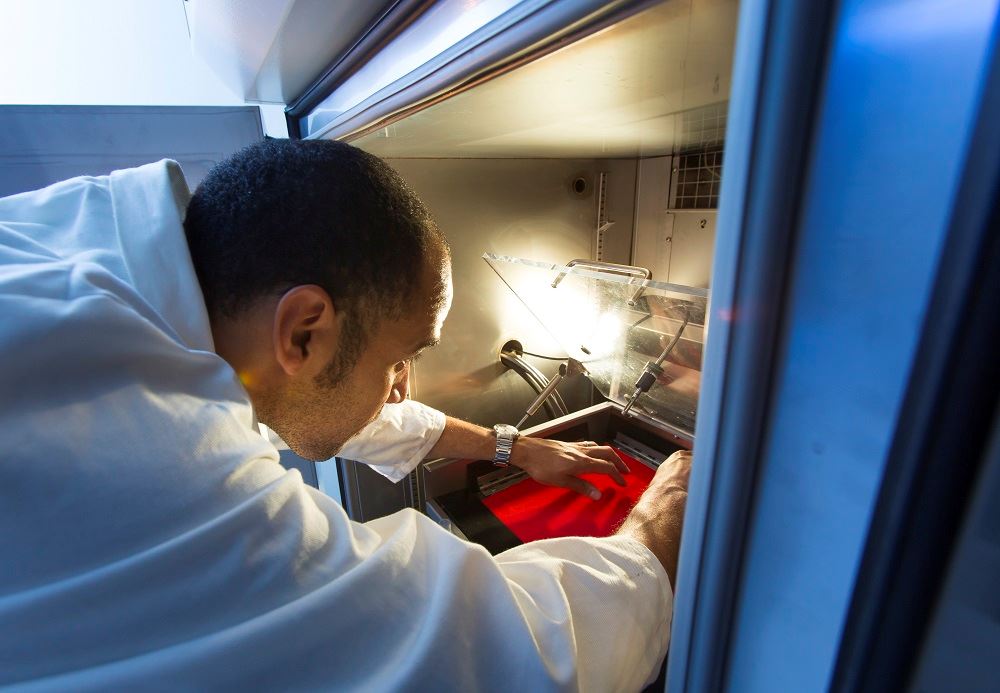

General description of lab and competence

The lab has the following main types of equipment:

- Autoclaves for exposing specimens to a combination of chemical environment, temperature and pressure

- A weatherometer for artificial weathering (programmed combinations of UV radiation, water, temperature)

- Orbital shakers for agitating the fluids during exposure

- Ovens and climate chambers (from ambient to elevated temperature, controlled relative humidity). This includes a high temperature oven for incineration of the polymer matrix (thermoset or thermoplastic) in composite materials/products.

- Vacuum ovens

- Freezers (down to -60 °C)

The aim of an ageing test can be to predict the lifetime of a material/product in a certain environment, or to compare material alternatives. If possible, the test conditions are selected so that the aging rate is higher in the lab than is real life (“accelerated ageing”).

Specimens retrieved during and after the ageing in lab (lasting from a few weeks to many months) are tested and analyzed. Regarding physical properties, the aged specimens are typically tested mechanically. This can be tensile testing of a plastic material or compression set testing of a rubber. See also the capabilities of our mechanical testing lab. Furthermore, the swelling/dimensions, weight/density and colour of specimens are typically measured. The chemical degradation that has occurred can be characterized indirectly (by e.g. measuring the viscosity) or directly (by e.g. spectroscopy or chromatography methods). See also the capabilities of our material characterization lab.

In addition to performing ageing test, we can develop/improve models for lifetime prediction. We can also contribute with relevant competence on e.g. chemical degradation mechanisms and permeability of gases and liquids through polymer materials. We can also assist in improving ageing tests, via a better understanding of the ageing mechanisms involved, to make the tests more realistic and to improve the lifetime predictions.

Equipment

Some details about the autoclaves and the associated infrastructure are given below:

- The autoclaves are made of different alloys (316/316L, titanium grade 4 and Hastelloy C-276), and equipped with mantel heaters

- Bespoke specimen holders are available for the different types of autoclaves

- The lab has infrastructure with gas bottle cabinet, pipes, panels, ventilation cabinets etc., for gases and liquids with design pressures of 400 and 680 bars, respectively

- Booster pumps for gases and liquids

- Rig for filling, liquid sampling and emptying autoclaves without any contamination from e.g., the atmosphere (oxygen or carbon dioxide)

- High-quality instrumentation to ensure that the exposure environment is close to oxygen free (< 0.01 ppm) if needed.

- In-lab control and data acquisition of the autoclaves (pressure and temperature)

In the autoclaves, specimens can be immersed in different liquids at both sub-zero and elevated temperatures, in combination with pressurization of the liquid or the gas phase. Control of e.g. the oxygen content in the closed vessel is possible due to bespoke rigs equipped with accurate instrumentation. Materials can be exposed to CO2 in the liquid and gas phase, as well as CO2 dissolved in a liquid, at different temperatures and pressures.

The weatherometer in the lab is an Atlas Xenotest 440.

Miscellaneous lab equipment:

- Data acquisition system for individual experiments

- Probes for measuring pH and electrical conductivity of liquids

- Instrument for measuring colour and gloss of surfaces

Relevant test standards

- ISO 4892-2 – Methods of exposure to laboratory light sources, Part 2: Xenon-arc lamps.

- NORSOK M-710 – Qualification of non-metallic materials and manufacturers – Polymers.

- ISO 175 – Plastics – Methods of test for the determination of the effects of immersion in liquid chemicals.

- ISO 1817 – Rubber, vulcanized or thermoplastic. Determination of the effect of liquids.

- ISO 23936-1 – Petroleum, petrochemical and natural gas industries. Non-metallic materials in contact with media related to oil and gas production. Part 1: Thermoplastics.

- ISO 23936-2 – Petroleum, petrochemical and natural gas industries. Non-metallic materials in contact with media related to oil and gas production. Part 1: Elastomers.

- ASTM D395 – Standard Test Methods for Rubber Property — Compression Set.

- ISO 815-1 – Rubber, vulcanized or thermoplastic. Determination of compression set. Part 1: At ambient or elevated temperatures.