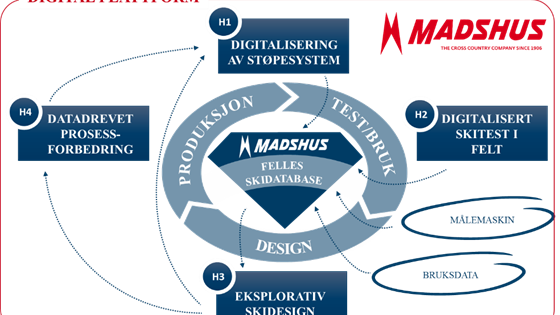

New technology creates opportunities to produce faster, more precisely and in smaller batches. In times of increased global competition, productivity and customization is important for remaining competitive.

Not only manufacturing companies are applying operations management. Its principles are widely applied within service industries, public sector and non-profit organizations. Operations management can support companies to reach objectives of a triple bottom line considering people, planet, and profit.

SINTEF has a broad expertise and experience within research on operations management. We work together with partners on topics ranging from strategic, tactical and operative levels. have summarized four main areas where we offer our services:

Production strategy

The production strategy should reflect the company's objectives and context. Examples of typical considerations are production network configuration, make-or-buy decisions, capacity considerations, required infrastructure and desired technology level.

Mapping and analysis of the current situation is an important starting point. At the same time, we see that digitalisation and industry 4.0 technologies provide new opportunities for drawing up the strategy map for the future.

Lean-based production systems

A production system is the company's approach to value creation and continuous improvement. Typically, this is based on principles and tools from the lean philosophy and other improvement programs.

SINTEF has broad expertise in how companies can drive systematic development of their production system. Involvement and participation from all employees is important in the process. Developing and sharing best practices can support a common language for improvement throughout the business. Developing the production system is a continuous process – not a project.

Production logistics

Logistics is the integrated flow of goods, information and money between players in a value chain. Production logistics is about the flow of materials from raw materials to finished products. Typical topics we work with are planning and management, factory analysis, development of layout and flow, performance measurement and circular solutions. Integrated IT systems play an important role in achieving good information flow - and material flow.

Supply chain management

All companies are part of a supply chain with a set of suppliers and customers. Supply chain management is about synchronizing supply and demand in a way that creates net value for the actors. It includes all phases, from design and sourcing, via production and distribution, to service and returns. Development of supplier collaboration and co-creation with customers are often key elements in achieving efficient and competitive value chains. Increased focus on sustainability and new, circular business models is vital in this process.

What we offer

SINTEF has extensive experience with research in production management. Our team has broad expertise in how companies can utilize methods and principles in production management to strengthen the industrialization of their business. Together with our industry partners, we develop specific solutions for your company. Good competence in strategic decisions, efficient logistics, continuous improvement and supply chain cooperation can ensure that production management is the company's success factors.

We guide companies to achieve increased productivity and competitiveness. Through analysis and development of business processes, we see how the use of new methods, systems, technology and business models can contribute to creating efficient and sustainable businesses.

We offer the following service:

- Factory analysis and preliminary projects

We can perform an analysis of your production unit. We have good experience with the tool "Rapid Plant Assessment", which can quickly point out areas where the shoe hits. Preliminary projects can be a great way to map the status of production and study the potential for improvement. Many of our long-term R&D collaborations start with specific preliminary projects. - Applied research

We work closely together to solve specific challenges in your company. Innovation projects aim to be applied research that contributes to increased value creation in your company. We know the policy instruments and can help with application writing. - Key notes and lectures

What new opportunities does Industry 4.0 provide for your business? What exactly is mass customization? What trends will characterize tomorrow's value chains? How do you make lean work in practice? Get in touch and we can agree on a topic and content together. - International research collaboration

We have extensive experience with EU projects and have a broad international network of relevant collaboration partners.