BioCoke4FAI - Bio-Coke for Ferroalloys Industry Production

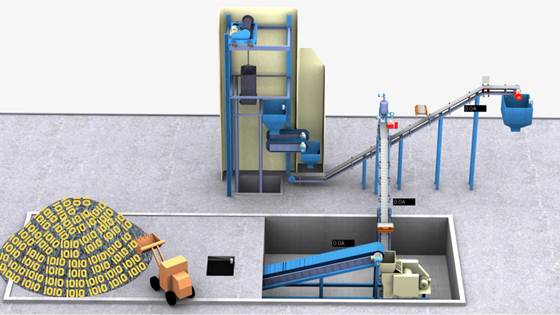

The BioCoke4FAI project aims to develop an innovative and economically viable technology for bio-coke production for the ferroalloys industry.

The BioCoke4FAI project aims to develop an innovative and economically viable technology for bio-coke production for the ferroalloys industry.

The production of photovoltaic modules generates significant resource flows, much of which currently becomes waste, including silicon kerf, graphite, and silica from ingot production.

Automotive car makers increasingly use light-weight aluminium structures to reduce the environmental footprint of cars during life-of-use (lower energy consumption) and to allow for the heavy batteries used in electric vehicles.

MADAM is a 4 year innovation project aiming at the development of production routes for high performance silicon-based material for additive manufacturing.

The RecirkIrRu project's goal is to demonstrate the effective extraction of valuable Iridium (Ir) and Ruthenium (Ru) from waste material into valuable intermediates for K.A. Rasmussen's further processing. The extraction will be possible by...

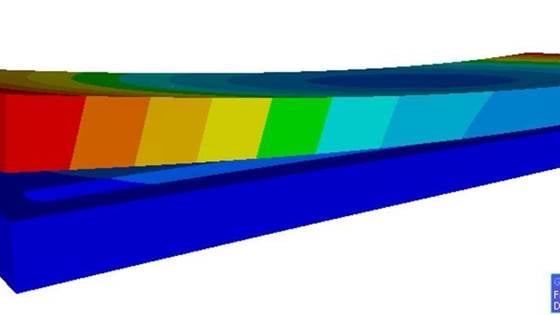

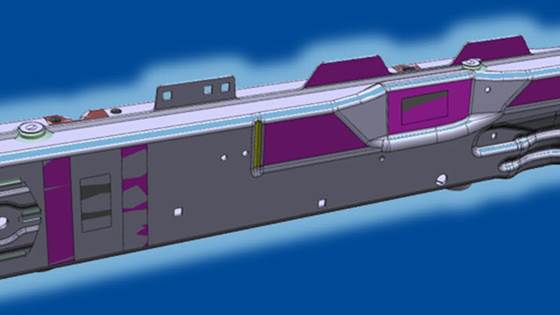

The ExtruTeC project will develop a digital framework for temperature control in aluminium extrusion. This involves detailed modelling and digital twins interacting with temperature sensors for process optimisation and precise temperature control.

The FurnAl project will develop numerical models and monitoring techniques for casthouse furnaces. This involves detailed modelling of the furnace process, and development of 'digital twin' coupled with monitoring of the furnace, for early warning of...

The HyPla project will establish a novel extractive metal production process where electricity and hydrogen replace carbon in metal ore reduction.

A collaboration between China’s Ministry of Science and Technology (MoST) and the Research Council of Norway (RCN) will pull towards a digitalization of the mining and metal industries.

PhysMet is an interdisciplinary center for research-based innovation (SFI) in physical metallurgy. Our goal is to establish knowledge and technology to realize new innovative material solutions in cost-effective, low-carbon production chains in the...

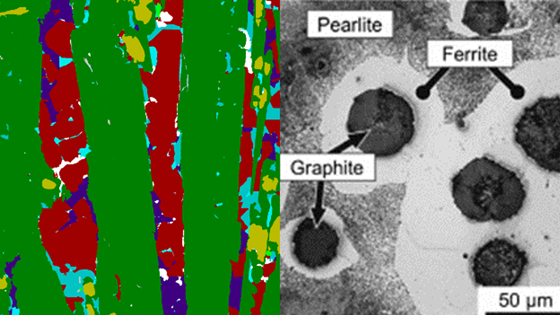

The FlexSi project will generate new knowledge on solidification and microstructure of ferro-alloys. FlexSi project will develop innovative magnesium treatments by optimizing the material microstructure leading to increased productivity in the...

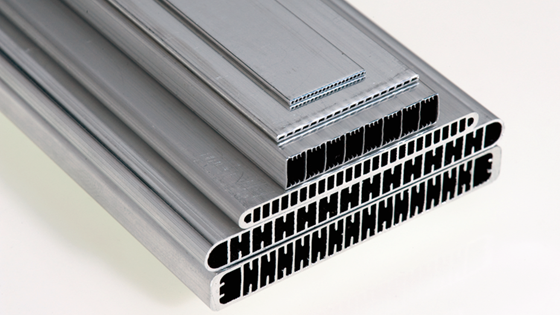

The LowEx project aims at developing sheet ingot materials with low CO2 footprint for automotive heat-exchangers. The goal is to reduce CO2 emissions from current levels by at least 1 ton per ton aluminium produced.

In this study SINTEF has focuses on circular economic opportunities that are expected to have a large potential for reducing the climate gas emissions associated with Norwegian consumption and production. Over a dozen circular strategies were...

The Ion4Raw project proposes an energy-, material- and cost-efficient new mineral processing technology to recover by-products from primary sources by means of innovative Deep Eutectic Solvent (DES) ionic liquids and advanced electro recovery, in one...

The EU-funded TARANTULA project aims to recover refractory metals from low-grade waste by developing a suite of cost-effective, scalable, and eco-friendly metallurgical processes. Following systematic research activities at a laboratory scale, the...

Aluminium is extensively used in food packaging because it provides a unique durability. Longer durability leads to less food wastage. The challenge is to make sure that the aluminium packaging is reclaimed and goes back into the circuit. The main...

The project aims to provide added value to profile- based components by including surface treatment in the processing of these products. The results from the project will be used as a basis to decide if investment in new lines for surface treatment...

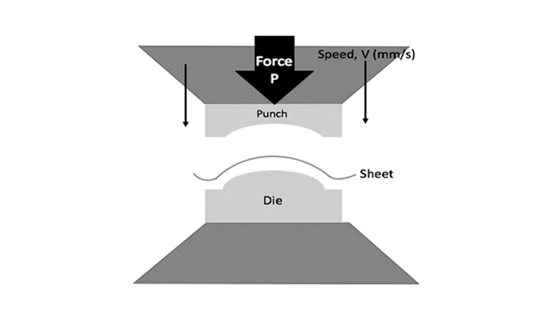

The goal of the project is to establish technology to make demanding components for automotive, enabling lighter cars with reduced CO2-emission.