Refractory metals like tungsten, niobium and tantalum have special characteristics that make them more durable and resistant than other standard metals. Features include a high melting point, high resistance to corrosion, and good heat and electricity conduction. Despite being classified as critical raw materials by the EC, fractions of these indispensable metals end up in mining waste streams and process scrap.

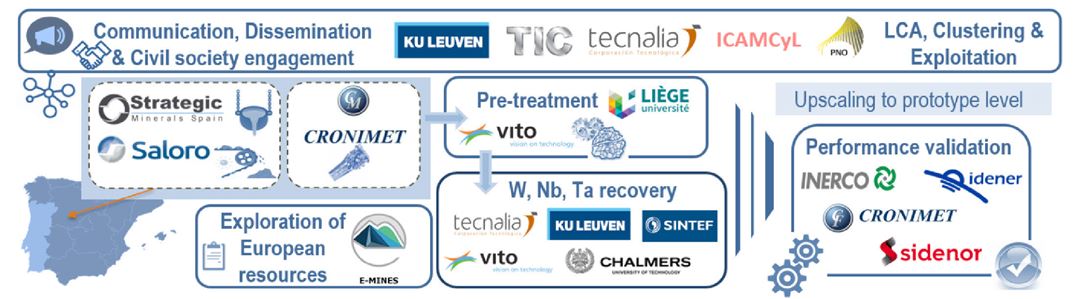

TARANTULA’s overarching objective is to develop a toolkit of novel, efficient and flexible metallurgical technologies with high selectivity and recovery rates with respect to W, Nb and Ta. As such, the project will promote (i) sustainable annual supply of secondary W at an amount equivalent to 50 percent of current EU W primary production, (ii) exploitation of Ta content equivalent to at least 120 percent of EU annual demand (iii) exploitation of Nb content equivalent to at least 5 percent of EU annual demand. TARANTULA will blueprint tailored Communication, Dissemination and Civil Society Engagement strategies with respect to obtaining and maintaining the 'Social License to Operate' for future heavy-duty metallurgical processing.

SINTEF is work package leader contributing with the development of novel production routes for Metal (M) and Carbide (MC) layers by electrochemical methods. Besides, SINTEF will optimize the production of metal oxide (MO) slurries for the manufacture of metal oxide coatings by thermal spray methods.

Partners

In total, the project has 16 partners from 6 different EU-countries:

- FUNDACION TECNALIA RESEARCH & INNOVATION, Spain, Coordinator

- KATHOLIEKE UNIVERSITEIT LEUVEN, Belgium

- SINTEF AS, Norway

- VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK N.V., Belgium

- UNIVERSITE DE LIEGE, Belgium

- OPTIMIZACION ORIENTADA A LA SOSTENIBILIDAD SL, Spain

- CHALMERS TEKNISKA HOEGSKOLA AB, Sweden

- CENTRE INTERNATIONAL D'ETUDE DE TANTALE ET DE NIOBIUM, Belgium

- SALORO SL, Spain

- STRATEGIC MINERALS SPAIN SL, Spain

- CRONIMET HOLDING GMBH, Germany

- SIDENOR INVESTIGACION Y DESARROLLOSA, Spain

- E-MINES, France

- INERCO INGENIERIA, TECNOLOGIA Y CONSULTORIA, SA, Spain

- PNO INNOVATION, Belgium

- FUNDACION ICAMCYL, Spain

This project has received funding from the European Union's Horizon 2020 research and innovation programme under GA No. 821159