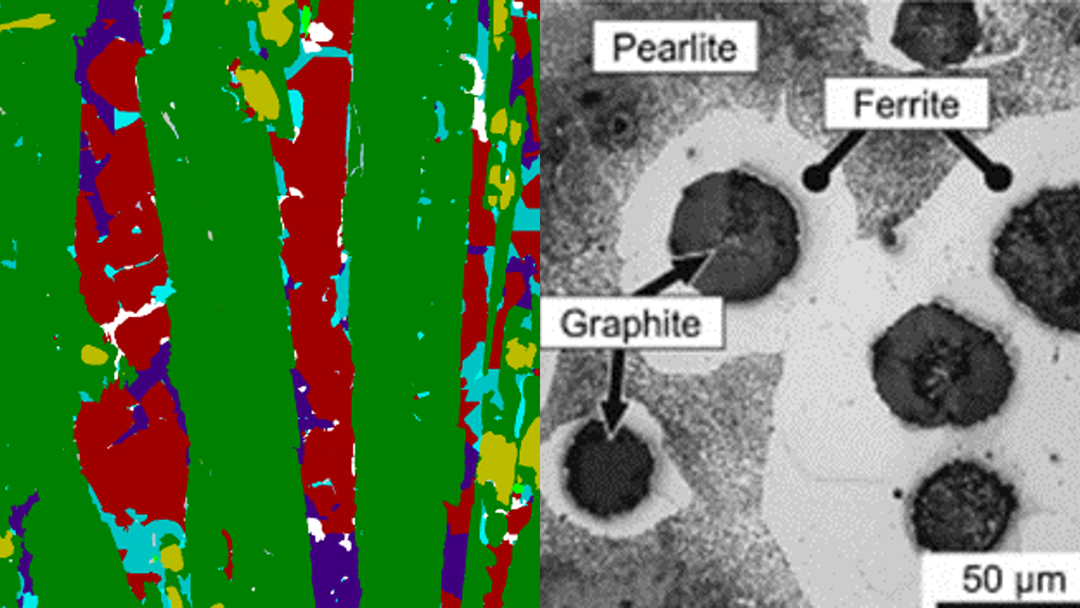

The FlexSi project will develop innovative magnesium treatments by optimizing the material microstructure leading to increased productivity in the foundries. The advantages of the new products will be demonstrated at industrial scale from batch material production. The project will combine lab-scale experiments, advanced characterization, numerical modelling and plant trials.

The FlexSi project will generate new knowledge on solidification and microstructure of ferro-alloys. New tools will be developed or improved that could be applied to other materials and applications (i.e. characterization procedures, material modelling, and lab-scale equipment). Generated data will be systematically stored to be better exploited and improve practice in the foundries.

Process industry is central in building the materials-loops of the circular economy. One challenge is the development of innovative materials while generating the data that will be used to improve the life cycle of the final products. This project will support data generation and storage (i.e. microstructure and particle size) on additives controlling cast iron component manufacturing and resulting properties.

SINTEF will contribute to this project by providing:

- Microstructure modelling

- Thermodynamic modelling

- Casting process modelling

- Advanced characterization

Partners: Elkem Silicon Products (project lead), Mandal Castings AS, Future Materials.

The project is funded by the Research Council of Norway project number 309990.