Forming laboratory

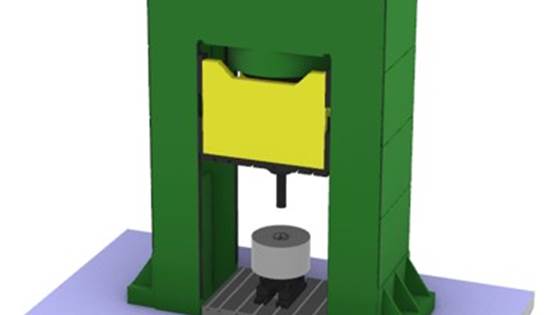

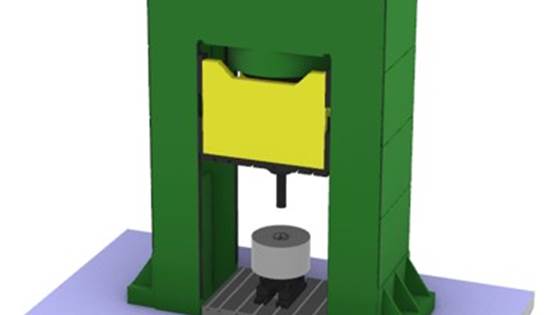

A fully instrumented 800 tonnes laboratory press, equipped with advanced tools for extrusion and forging, together with our skilled research staff, constitutes the backbone of our forming activity.

A fully instrumented 800 tonnes laboratory press, equipped with advanced tools for extrusion and forging, together with our skilled research staff, constitutes the backbone of our forming activity.

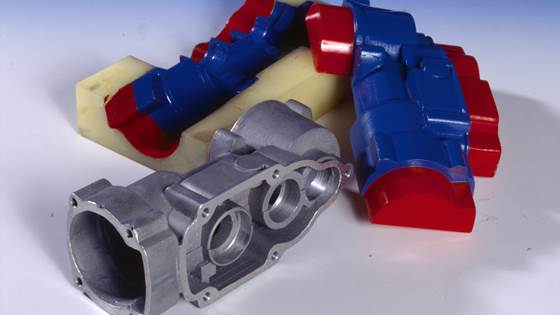

In our foundry and recycling laboratory we work with casting, recycling and melt treatment of metals such as aluminium, iron, steel, titanium, magnesium and copper-based alloys.

The gas conversion laboratories at SINTEF consists several customizable units for investigating catalytic reactions at industrially relevant conditions.

The laboratory in Oslo is used to characterize fundamental transport properties (such as permeability, diffusivity and solubility) for membrane and barrier materials.

The high temperature hydrogen and fuel cell lab is equipped to test fuel cells and electrolysers operating up to 1100 °C and up to 10 bar.

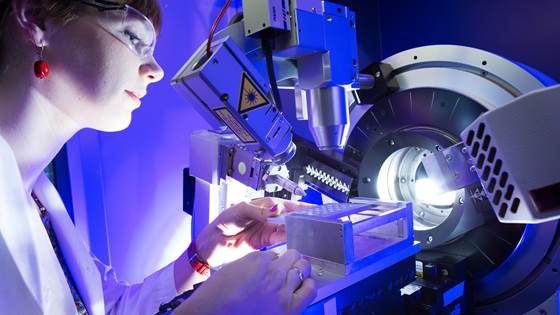

The High Throughput laboratory can be divided in three main activates: 1) design and construction of high-throughput equipment, 2) parallel synthesis of materials, and 3) parallel screening of materials properties. We provide automated custom made...

The robotic screening facility at SINTEF are optimized for high throughput analytical and cultivation work and enables us to process of thousands of samples or cultures per day.

In the lab in Oslo we can test membranes, fuel cells and electrolysers under real operating conditions. Experiments can be carried out at pressures up to 30 bars and temperatures up to 1100°C.

Additive manufacturing is a growing competence field for the research group. The group already contributes to several national and international projects within this emerging and exciting field.