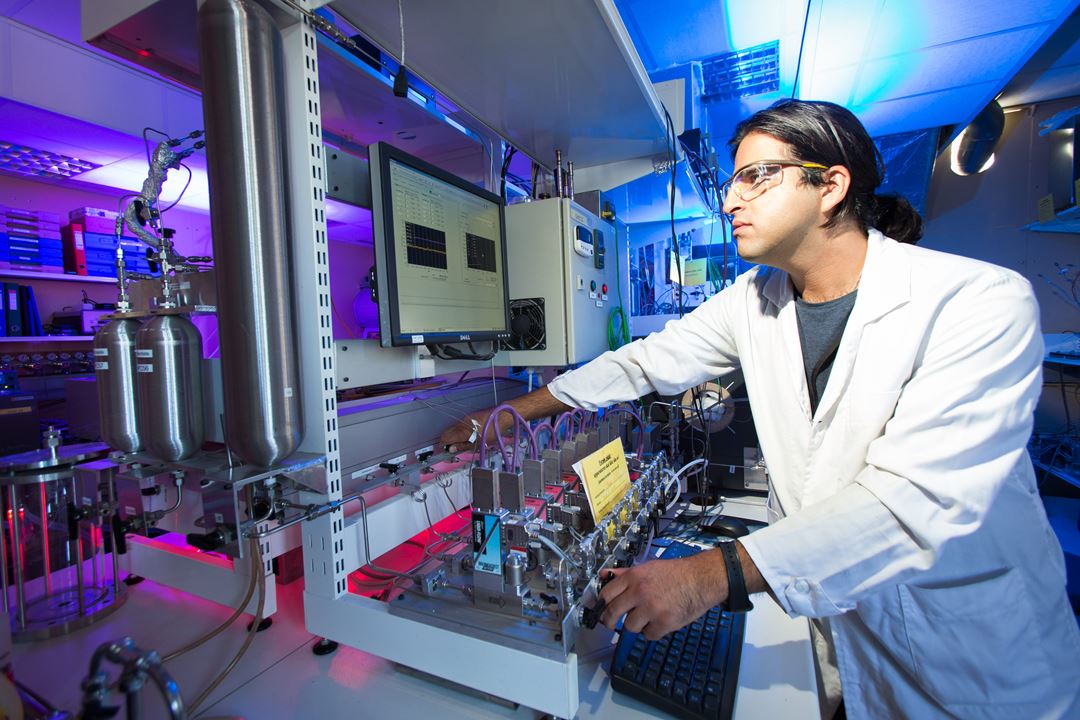

The lab is equipped with a range of test station for various geometries including flat and tubular cells. Characterisation of gas permeability, selectivity, kinetics, corrosion and stability can be performed by use of advanced equipment under realistic operating conditions. The lab is based around comprehensive gas infrastructure which allows for controlled gas mixtures of O2, H2, N2, CO, CO2, CH4, Ar og He. The lab is automated and continuous long-term testing can be performed.

Main equipment:

- Test units for flat and tubular membranes, fuel cells and electrolysers

- Testing up to 30 bars pressure and 1100°C

- Measurement of gas permeability, selectivity, kinetics, corrosion, electrical transport properties and stability

- Electrical characterisation including impedance spectroscopy for measurements of conductivity and EMF

- Fixed bed-reactor

- Thermogravimetry (TG) at high pressure and temperature (30 atm, 1100°C)

- Available standard gases: O2, H2, N2, CO, CO2, CH4, Ar og HeGas analysis by GC (gas chromatography) and MS (mass spectrometry)

- Detectors for H2 and CO that automatically shut off gas supply upon leakage

- LabVIEW software for equipment control, data handling and automation