The European process industries play a vital role in achieving climate neutrality by 2050, currently responsible for 20% of greenhouse gas emissions and 25% of final energy consumption in Europe. A significant portion (66%) of industrial energy use is dedicated to process heating. While technologies like heating electrification can support decarbonisation, challenges such as high upfront costs, low digitalisation, and the need for further R&D on heat pumps remain. Sustainable heating technologies aim to improve energy management at the plant level through peak reduction and load shifting.

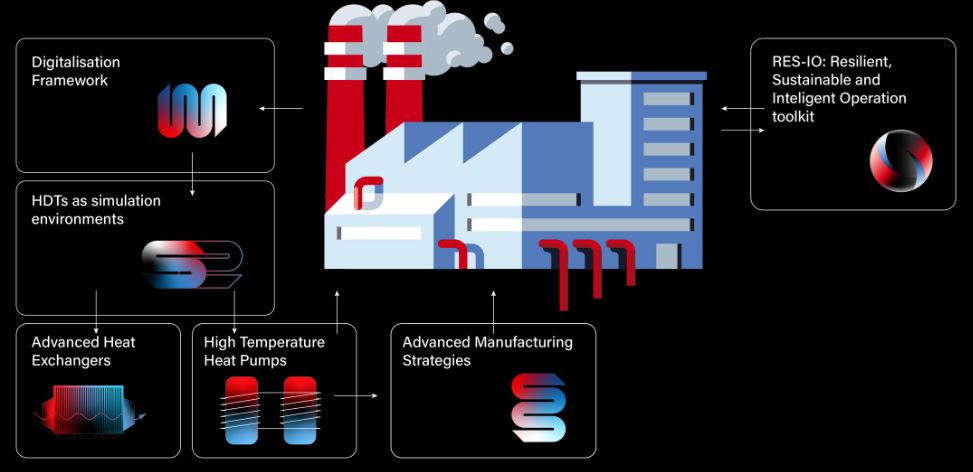

The StreamStep project aims to improve heating energy management in industrial processes. The project will deploy five innovative heat exchanger prototypes for waste heat across temperatures from 135°C to over 1400°C. High-temperature heat pumps will enhance heat recovery, achieving outlet temperatures of 150°C and 215°C, with improved performance through ejector technology. Advanced manufacturing techniques and novel material alloys will enable these innovations. The system will be demonstrated across five sectors, copper, ceramics, silicon, plastics and oil & gas, with significant impacts on waste heat recovery, productivity, and energy flexibility.

StreamSTEP is an Innovation Action project, supported by Horizon Europe (Grant no. 101178351) with an approved budget of €14,999,977. StreamSTEP involvies 30 organizations from the EU, Norway, Switzerland, and the UK.

In StreamSTEP, SINTEF Industry serves as the Project Coordinator and manages the industrial-scale demonstration of silicon at Solcellesilisium krystalliseringslaboratorier in collaboration with ELKEM, acting as the end-user. Additionally, SINTEF Industry is responsible for material selection and the 3D printing (Laboratory for additive manufacturing) of heat pump components. SINTEF Energy contributes its expertise in heat pump design and prototyping, and is developing a prototype that incorporates 3D-printed components.