In addition, we focus on innovation and advanced production to create new industries and jobs. SINTEF can offer access to unique infrastructure and academic networks. We use our process technology expertise across the entire value chain from raw materials through processing to products to increase value creation in industry and solve tomorrow's challenges.

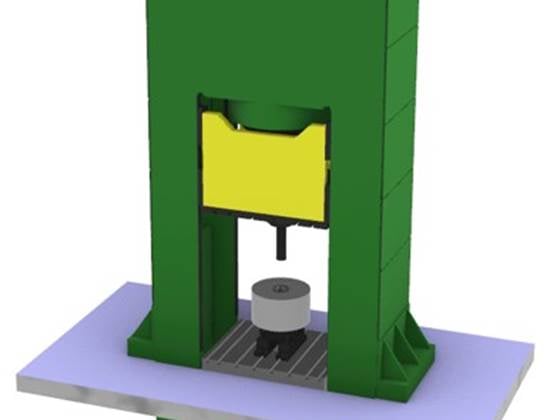

Catalysis Pilot Laboratory

The catalysis pilot lab is a laboratory designed to conduct experimental campaigns that simulate industrial conditions for a range of catalytic processes.