What is additive manufacturing (3D printing)?

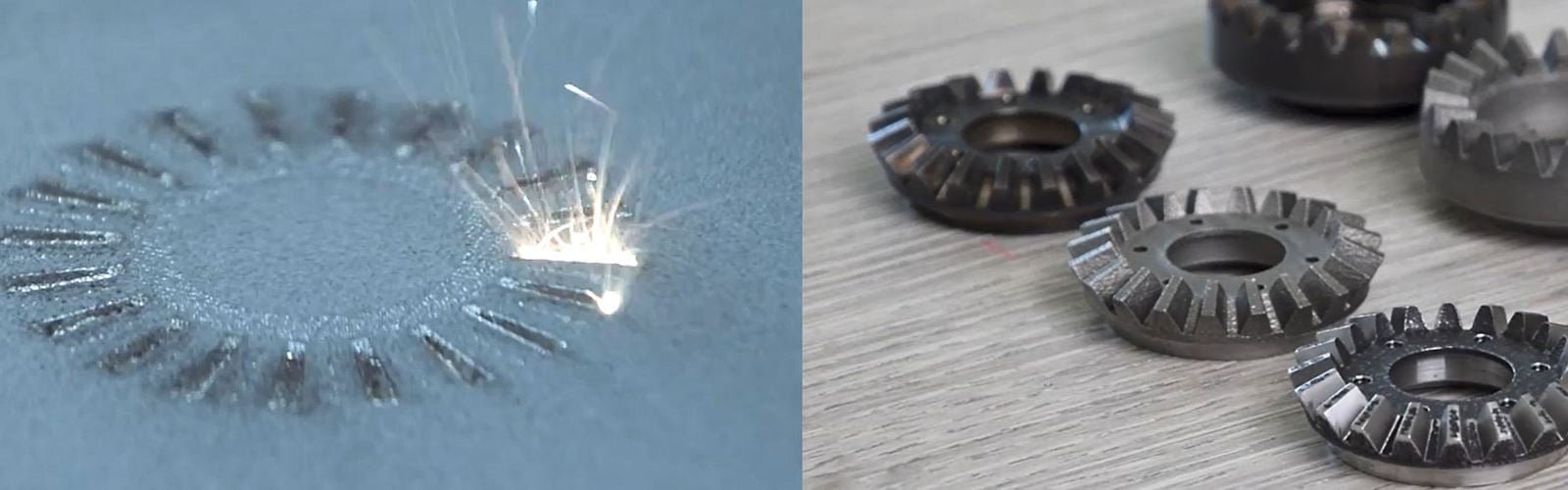

Additive manufacturing is a production method where an object is built layer by layer based on a digital 3D model.

Additive technology allows for possibilities in construction and design that have previously been unattainable.

By using this technology, you can produce cost-effective products that have a lower environmental footprint.

Here are some of the benefits of additive manufacturing

- The technology is flexible and can be used to build complex parts in a short time.

- Little material is used compared to traditional production.

- Additive manufacturing can be combined with and complement conventional production methods.

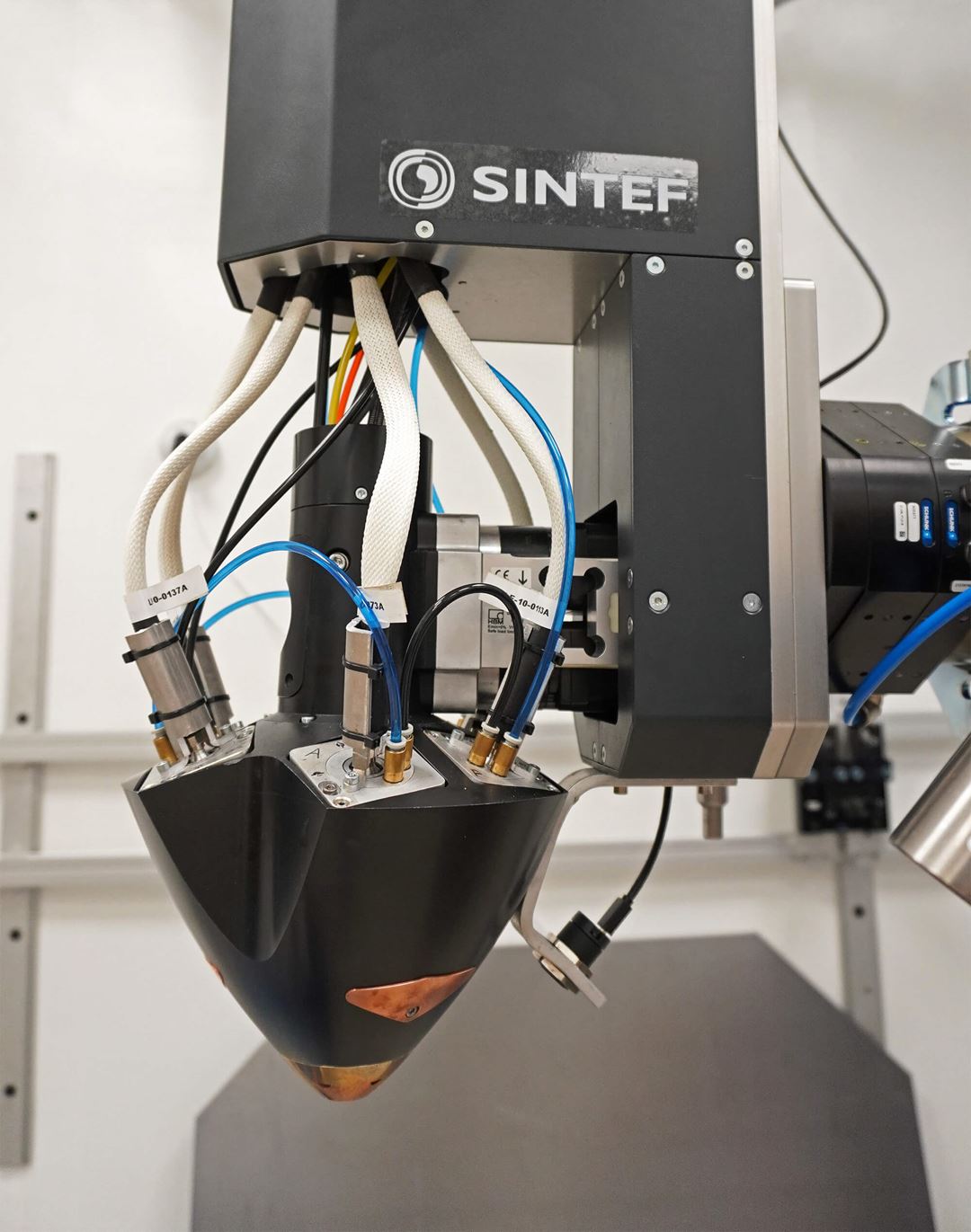

What is SINTEF doing in the field of Additive Manufacturing?

SINTEF is involved in many aspects of AM and associated technologies. The topics range from material development and "analysis-based design for additive manufacturing" to assessing product properties and developing new applications.

SINTEF also has facilities for AM trials, both lab/R&D equipment and industrial machines. Some facilities are shared with NTNU, which is an important partner in many projects.

SINTEF's expertise in Additive Manufacturing

SINTEF has broad expertise in AM via research groups in Trondheim, Oslo, Raufoss and Porsgrunn.

SINTEF's expertise covers areas such as process/machine technology, materials technology, numerical simulations, digitalization aspects, standardization and new business models.

Based on this, SINTEF can help various industry segments to make use of AM.

Some key words about SINTEF's expertise and projects:

- General expertise in industrial additive and hybrid processes, as well as associated materials and material properties (metals and plastics/composites)

- Standardization and industrialization

- Simulation tools for AM, e.g. topology optimization of components and simulation of AM processes

- Digital support for AM

- Molds/tooling made with AM

- AM of reactors etc to the chemical process industry

- AM in the construction industry

- Bioprinting

- AM with functional ceramic materials