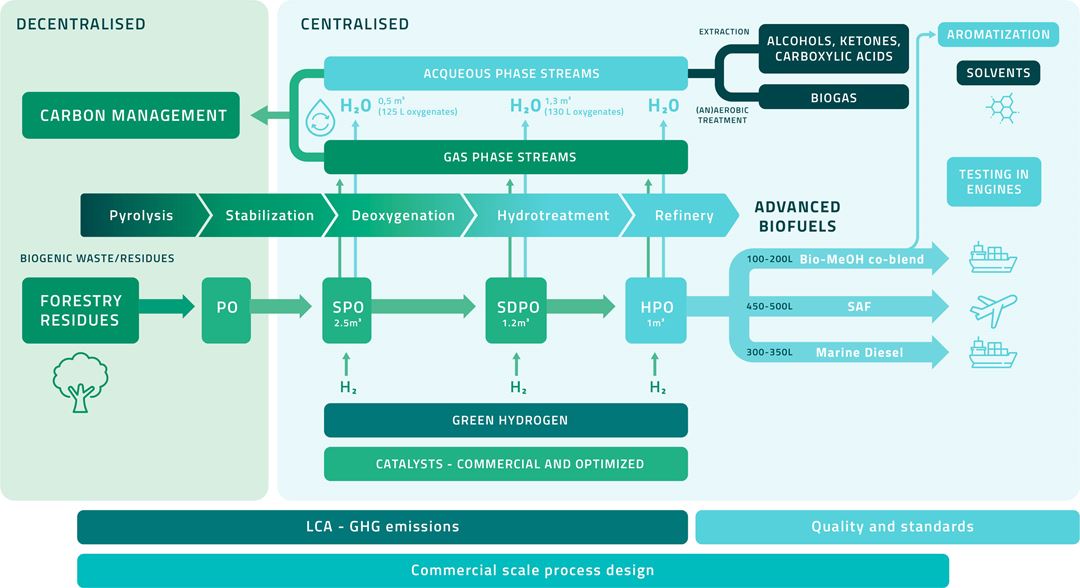

FUEL-UP project aims at producing simultaneously the key renewable SAF and marine fuels from 100% biogenic feedstocks (primarily forestry residues) through pyrolysis and downstream upgrading of pyrolysis oils, reducing GHG emissions of the corresponding transportation sectors. The project will demonstrate at TRL6-7 the production of sufficient aviation and marine fuel in the project, transforming 1000 L of hydro-processed pyrolysis biooils (HPO) to 450-500 L SAF, 300-350 L marine diesel and 100-200 L marine fuel Naphtha/Bio-methanol co-blend for testing. The key challenges are to de-risk and optimize stabilisation, hydrodeoxygenation, hydrotreatment and hydro-isomerisation steps; including optimisation of catalysts and scalability.

FUEL-UP will ensure the fuel quality meets standards and engine specifications. The produced SAF will be tested according to aviation standards (Tier 1, 2 & 2.5), to qualify them with D4054 certification and develop a strategy for certification through introduction to EU Clearinghouse. The produced marine biofuels (marine diesel and Naphtha enhanced Bio-methanol co-blend), will be assessed with marine engine testing performed according to ISO 8217 and ISO 8178 standards.

FUEL-UP will also maximise the valorisation of all carbon side streams (gaseous and aqueous), with aqueous phase treatment and extraction up to 80%, resulting in at least 200 L valuable compounds /t HPO, followed by subsequent conversion into high quality biogas. Environmental impact of the value chain will be assessed to show up to 80% GHG emission reduction compared to fossil fuels and provide scenarios for green hydrogen production. Process engineering will ensure scale-up of technologies to reach commercial scale by 2030 and replication in 10 sites by 2035 and 25 sites by 2040, unlocking the production of >2Mt of sustainable fuels.

With a long history in monitoring potential breakthrough technologies in biomass conversion (2014 FastCard, 2017 4Refinery, 2020 Waste2Road, 2018 Pulp&Fuel and 2017 FME Bio4Fuels), the process technology department at SINTEF Industry has been actively supporting the derisking of advanced biofuel technologies through R&D throughout the different steps of the technology development (i.e. TRL). Fast pyrolysis of sustainable biomass sources has been identified as a key technology for the production of sustainable fuels for the hard to abate sectors. FUEL-UP comes to close the gap of large volumes of 100% biogenic fuel demonstrating the full value chain from biomass to jet and marine engines by upscaling production.

SINTEF’s role in the project

- Coordination and project management (Research group of Kinetics and Catalysis - SINTEF)

- Hydroprocessing Pilot test campaigns (lab unit at Tiller) Catalysis Pilot Laboratory - SINTEF

- Catalytic material development and understanding (Research group of Kinetics and Catalysis - SINTEF and Research group of Functional Materials and Chemistry - SINTEF)

- Process design and simulations (Research group of Kinetics and Catalysis - SINTEF)

- Pilot tests of separation technologies (Research group of Kinetics and Catalysis - SINTEF)

- Mass spectrometry (Mass spectrometry - Advanced research-based analyses - SINTEF)

- Tests on marine engines (Maritime Energy Systems - SINTEF)