Objective

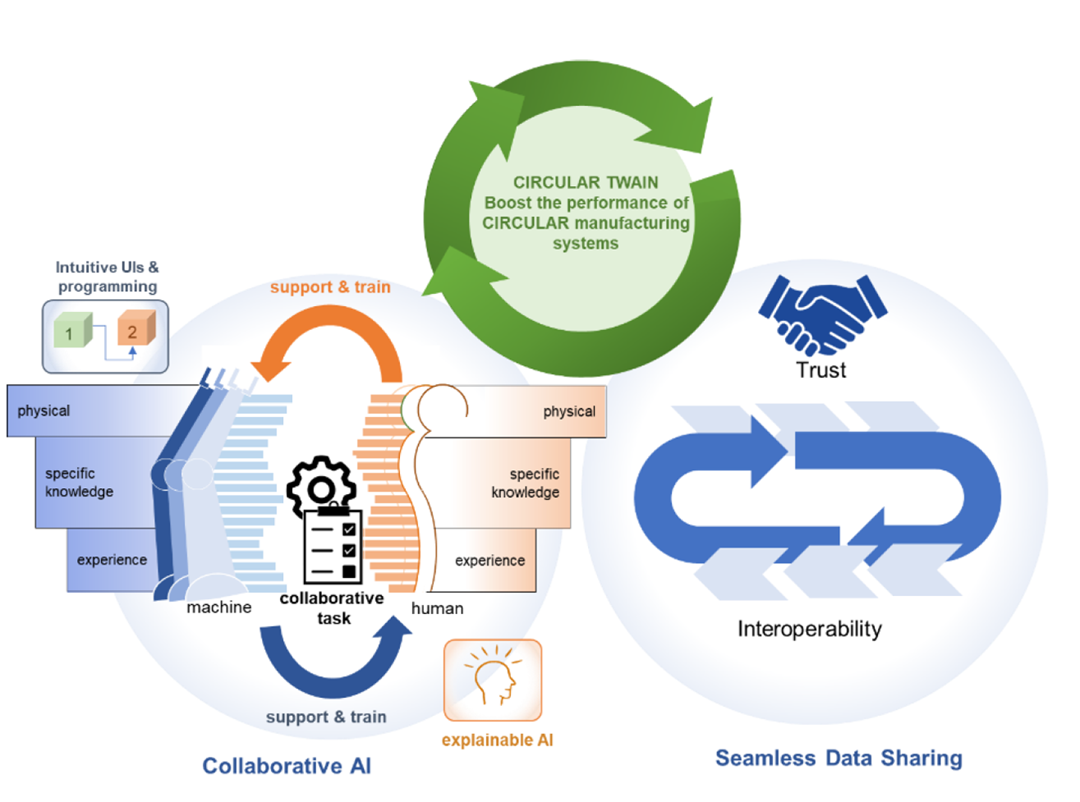

Circular TwAIn is developing a novel AI platform for circularity with the aim to increase the performance, resilience, and sustainability of direct manufacturing and process industries. The project is based on two fundamental concepts:

- Collaborative AI: AI technology is seen as meaningful support for the human worker on the shopfloor – not as a replacement. The collaborative approach aims to reach performances that man or machine, acting independently, cannot reach.

- Seamless Data Sharing: Technical and semantical interoperability as well as trustworthiness between all actors of the circular manufacturing system (based on the International Data Space policy and Gaia-X standard, which ensures data sharing in-line with European data values).

Following the Circular TwAIn concept of “Collaborative AI”, the human and the machine/AI share, combine and extend their experience, specific knowledge and physical capacities in a mutual and collaborative manner to fulfil a certain task more efficiently. The training of the AI-system is carried out through intuitive and effortless teach-in programming approaches. At the same time, the worker can learn from the AI system as it provides transparent explanations/reasons for each of its decisions (XAI).

The Circular TwAIn concept of “Seamless Data Sharing” is built on the upcoming Gaia-X standard and is based on the exploitation of the International Data Space policy, namely:

- Data sovereignty: the data owner always specifies the terms of use of the data provided.

- Decentralized data management: management remains with the respective data owner.

- Easy linkage of data: the platform facilitates the integration and use of data between participants.

- Trust: All data sources and data services are certified against commonly defined rules.

- Security: Data exchange is secure across the supply chain.

SINTEF's role in the project

SINTEF will mainly participate in WP4 and lead Task 4.1, which contributes to the development of information models for materials, products, processes, and assets. In this task, recommended industry standards and relevant ontologies will be adopted to develop the semantic information models for the Digital Twins, Dataspaces, and Machine Learning/AI algorithms. Our main goal is to address the semantic interoperability challenge with regard to knowledge representation and data exchange among different stakeholders in the circular manufacturing environment. SINTEF also actively contributes to WP3 and WP6 where the developed information models will be used to define the conceptual framework and applied to the industrial pilots.

Project website

Funding

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No 101058585.