The 13th and 14th of June, the first general assembly of the EU-project QU4LITY took place. The project group came together in Ljubljana in order to share the results of the first half year.

45 partners in 13 different countries are joining QU4LITY, a Horizon 2020 project in which digital production platforms are playing a central role. Digital production platforms are getting a more and more important role in managing competitiveness, and in incorporating new technologies, applications and services.

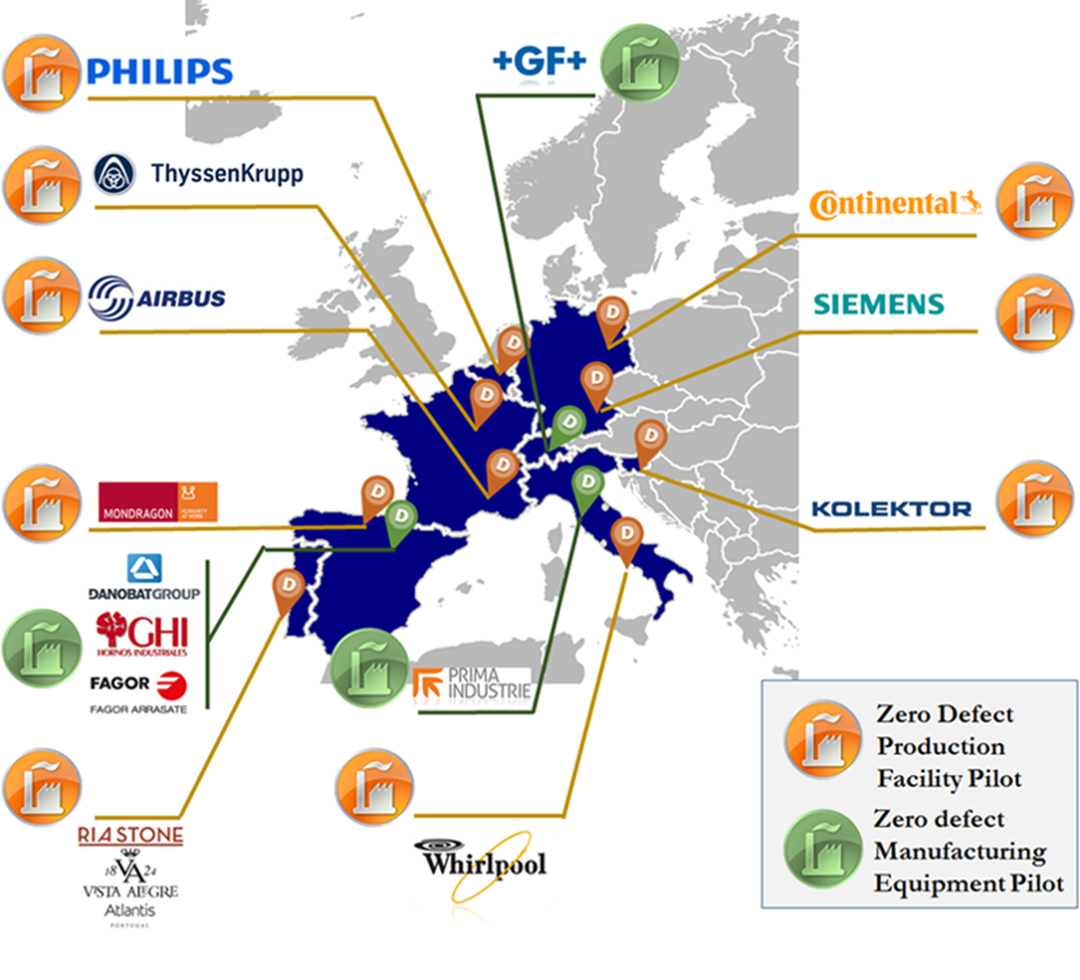

The project exists of 14 pilots, in cooperation with Siemens, Philips, Airbus, Wirlpool, Continental, Schneider El, Thyssenkrupp, Ria Stone, Kolektor, Danobat, Fagor, GF, Prima and Visual Components. �� After the first half year, the cases for the pilots are getting shape, tells project leader Ragnhild Eleftheriadis in SINTEF Manufacturing.

– During this project, the focus lies on the harvesting of data in a quality perspective, with empathize on data collection in order to create a good product or process. Some pilots have quite similar processes when it comes to data collection, others have different approaches. Our main goal is to create one platform for autonomous quality control.

– The pilots are build up around different themes. We are looking at factory lines of healthcare and electronic products for example - In specific, at autonomous control of electronic machinery for component production. One of the cases we are working on, is a platform for data integration of different sites, as well as a holistic quality platform for a dryer factory on white goods.

Another theme is the injection moulding of parts, and the detection and removal of defects in the injection tool, as well as acoustic control systems for steering gear, and a trade-space framework for autonomous design. A furnace and assembly line for ceramic tableware, using adaptive control technology, is one of the themes as well.

– It has been an interesting general assembly, where SINTEF had the lead in several discussions, tells Ragnhild Eleftheriadis. SINTEF is leading is two tasks in both work package 2 and 4, focussing on a vision on autonomous quality, as well as equipment for autonomous quality.

– We are also involved in 3 of the 14 pilots. In the first pilot, with Continental, we are looking at data acquisition on industry 4.0 machinery, making electronic circuit boards. In the second pilot, with Philips, we are looking at human interaction in a fully automatic assembly on "one blade razors", and in the third pilot, with Danobat, a machine tool builder in Spain, we are looking guidelines for how to collect and harvest data in order to optimize one of their machine tools.