We’ve all heard about ‘power houses’ – buildings that in the course of their lifetimes generate more energy than they consume. Now is the time to launch ‘power roads’. The idea is that over the course of their lifetimes all constructions, including roads and bridges, should generate more energy than they consume.

FACTS:

- The Power Road project is closely related to the Power House project that investigated the requirement that a construction should generate more energy than it consumes.

- Norway was the first country in the world to open an office building renovated according to the Power House principle.

- NTNU and SINTEF are currently establishing a separate joint project called Power Road.

- It's difficult to calculate energy consumption and emissions linked to a road, although the results of some survey measurements may provide us with some rough approximations. Road building is estimated to generate between 25 and 40 tonnes of emissions per million kroner invested (2012-kroner) – or about 4,000 tonnes per kilometre for a four-lane highway. Operation and maintenance appear to have little impact on emissions.

First of all, the energy used during their construction must be reduced. Then the finished roads and bridges themselves can generate energy. Solar panels can be installed on bridges, wind turbines can be integrated into the constructions, and we can extract energy from the currents and waves in the water below the bridges. All with the aim of making net consumption zero.

Utopia? “No – we’re well on our way”, says Berit Laanke at SINTEF Building and Infrastructure.

New project

The Norwegian Public Roads Agency (Statens Vegvesen) has been interested in energy use within the social sector for many years. The great project of the future is construction of the ‘ferry-free’ E39 motorway in western Norway. This will undoubtedly require a new approach, including roads that generate more energy than they consume in construction.

“We’ve wanted to incorporate ideas like this as part of a research project, and have accumulated a good deal of experience as a result of our being a partner in the Zero Emission Buildings research centre that focuses on environmentally-friendly energy”, says Laanke. “And we’re also in close contact with the Powerhouse Alliance responsible for the so-called ‘Plusshuset’ at Kjørbo in Sandvika”, she says.

Partners from NTNU and SINTEF have now set up a new project called ‘Power Road’, and are working to stimulate interest and obtain funding. According to Laanke, a lot is happening in this field around the world. So the first step is to make sure that project participants are fully aware of the big picture. Norway is in a unique position because of the frequency of snow and freezing weather. For this reason, foreign approaches may not be so easy to integrate here.

“In the short term SINTEF is looking to launch a small number of specific projects”, says Laanke.

“This autumn we’re focusing on energy generation linked to bridges, involving systems integrated into safety barriers and noise screens. We’re also looking into how materials production can be made more energy efficient by using locally-sourced stone, and are working together with Statens Vegvesen on a project proposal involving the electrification of heavy-duty transport vehicles, incorporating a kind of ‘rubber track’, equivalent to a tram running on rubber wheels.

Locally-sourced stone

Rock and stone must be extracted as part of all road construction projects, and a plan for its re-use must be in place. But there are many examples of where such planning has been inadequate. Instead of re-use, stone removed from tunnels has been moved to disposal sites, while new stone has been quarried and transported over distances of several tens of kilometres.

The SINTEF researchers are trying to work out how we can be smarter at re-using extracted stone in asphalt, concrete or road building applications.

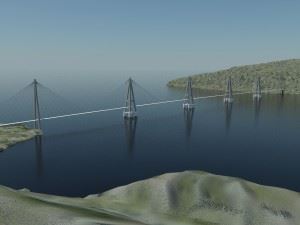

The new E39 will involve several bridges, for example this stay cable bridge with floating med flytende pontoons. Photo: Vegvesenet.

Click to open

“Our current system takes no account of the contractor’s role in this conundrum”, says Laanke. “At the moment they simply get paid for transporting rocks – not for looking into local and sustainable solutions”, she says. For this reason, we need ideas from developers such as the Norwegian Rail Services Agency (Jernbaneverket) and Statens Vegvesen. Developers should also be looking into how strict the requirements should be when it comes to rock materials earmarked for other uses. Perhaps the best solution would be to loosen up the requirements if re-use applications enable us to do so”, says Laanke.

When a bridge generates energy

By Norwegian standards, a new ‘ferry-free’ E39 will involve a massive investment in bridge-building. In this case it will be possible to integrate solar panels and wind turbines into the constructions, and extract energy from the currents and waves in the water below.

The report from the project ‘A ferry-free E39’ has demonstrated the need for more technological advances as a basis for robust solutions for this type of integrated energy generation project. It will also be important to have a debate about the role that local and renewable energy generation will play in the overall energy market.

However, the majority of Norwegian transport infrastructure constructions are located in forested and mountainous areas and do not involve fjord crossings, so the researchers cannot refer to examples of energy generated from Norwegian bridges.

Energy producing bridge with wave energy. Illustartion: Ben-Tommy Eriksen/NorNet

Click to open

For this reason, SINTEF researchers envisage that, in the future, new electricity-generating materials will be developed and integrated into the asphalt, and that other ideas will emerge on the issue of energy generation from roads.

“Electric cars are already able to recharge themselves as they go downhill”, says Laanke. “Will it be possible to harvest some of this energy if the car battery is fully charged? Cars exert a pressure on the surface they roll along, so perhaps we can capture this energy for re-use? The same principle has been applied on football pitches. As the players run around, lights are activated to illuminate the pitch”, she says.

Smart choices at every stage

The Power Road project must focus on renewable energy generation combined with lower energy consumption. The latter can be achieved by painstaking road designs using locally-sourced building materials and smart operational systems.

“If we look at the entire lifecycle of a bridge”, says Laanke, “we can develop a design that involves both a reduction in materials consumption and energy-efficient maintenance. We can select energy-efficient and locally-sourced materials, and think in terms of re-use once the lifetime of the bridge has expired. Perhaps the materials can be re-used for concrete or other road construction applications.

Bridges are built with a lifetime of 100 years in mind. In this context, even the smallest contribution may make a crucial overall impact”, she says.

The new, ferry-free E39 vil include lots of bridges. This bridge is planned over Sognefjorden. Ill.: Statens Vegvesen.

Click to open

Road transport with climate change in mind

In the long term, the research group behind the Power Road project will want to establish a collaborative forum. According to Berit Laanke, a number of organisations have already shown some interest.

“We envisage the development of a world-leading research and innovation cluster based in Norway, involving expertise from competent private sector organisations and research centres. Today, close to forty Ph.D. students at NTNU are involved in the ‘ferry-free’ E39 project alone”, she says.

She sees the project addressing locally-sourced stone as being linked to several of these doctorate studies. And the Power Road innovation project will be applying to the Research Council of Norway for funds.

“We hope to be launching the first projects in the spring of 2016”, she says. “With the dedicated commitment of public sector organisations such as Statens Vegvesen, I’m convinced that the Power Road project will succeed”, says Laanke.