We combine numerical modelling and experimental research with the aim of achieving a detailed understanding of physical phenomena and better process understanding, as well as improved combustion chamber design and operational conditions for the industrial process in question.

We work witin these areas:

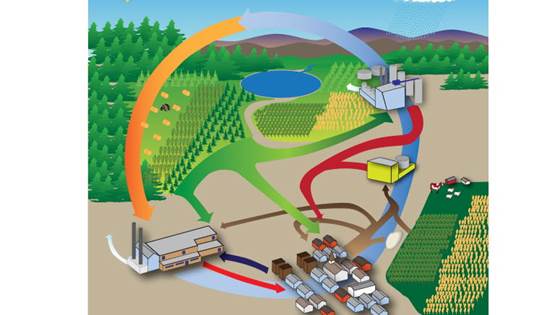

• The design and optimisation of combustion processes

• Emissions reduction (NOx, particles and greenhouse gases)

• Ash-related problems such as corrosion, and slag and deposit formation

Methods:

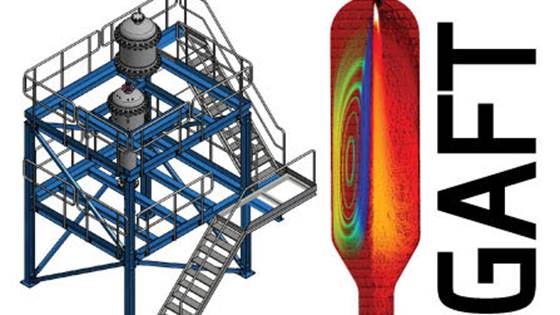

- Computational fluid dynamics (CFD), which employs computer-based simulations to analyse systems that include flow, heat transport and associated phenomena such as chemical reactions. The method can be used to study a wide rangeof industrial and non-industrial processes such as the design of combustion engines, industrial furnaces and combustion chambers (e.g. gas turbines). We are using both commercially available and in-house developed software (RANS, LES and DNS) at a variety of levels of detail.

- Kinetic modelling. Ideal reactors can be used to conduct comprehensive studies of detailed reaction mechanisms under ideal flow conditions. Industrial processes can be modelled as a network of ideal reactors. These analyses can be conducted relatively quickly compared with CFD simulations, and can be carried out separately or in combination with CFDs.

- Thermodynamic modelling, involving thermodynamic equilibrium calculations, is a method based on the minimisation of Gibbs energy. It provides predictions of the stable components making up complex (multi-element/multi-phase) systems under given conditions of temperature, pressure, etc. The method, also known as Global Equilibrium Analysis, is a useful tool for obtaining valuable and reliable information about a system's stability and the formation of different components (speciation). It is also used to gather information about the underlying chemistry. Equilibrium calculations are an effective tool that complements experimental studies. Current research is focused on problems such as the detailed chemistry of ashes derived from biomass combustion and gases obtained from gasification, as well as metallurgical processes.

Why choose SINTEF?

- We are a leading research group in the field of numerical modelling of combustion and other thermochemical processes.

- We have high levels of expertise in the use of CFD codes, chemical kinetics and equilibrium computation software, developed both commercially (e.g. Fluent(c)) and in-house.