Annual reports

About HighEFF

Energy preservation and security is a global challenge. There is a global energy shortage, and the way we use and produce energy today is causing greenhouse gas emissions contributing to climate changes.

HighEFF will build an internationally leading Centre for strategic research within industrial energy efficiency. Supporting the EU energy targets, HighEFF will enable a 20-30 % reduction in specific energy use and 10 % in emissions.

Our contribution to a more sustainable world

By increasing energy efficiency, value creation and competitiveness, while decreasing greenhouse gas emissions in a broad span of industrial processes across sectors, HighEFF contributes towards all 17 UN sustainable development goals (SDGs). But we have chosen to focus on four SDGs we consider as the most relevant and where we hope to achieve significant impact through our research.

Read more about the sustainable development goals on our website.

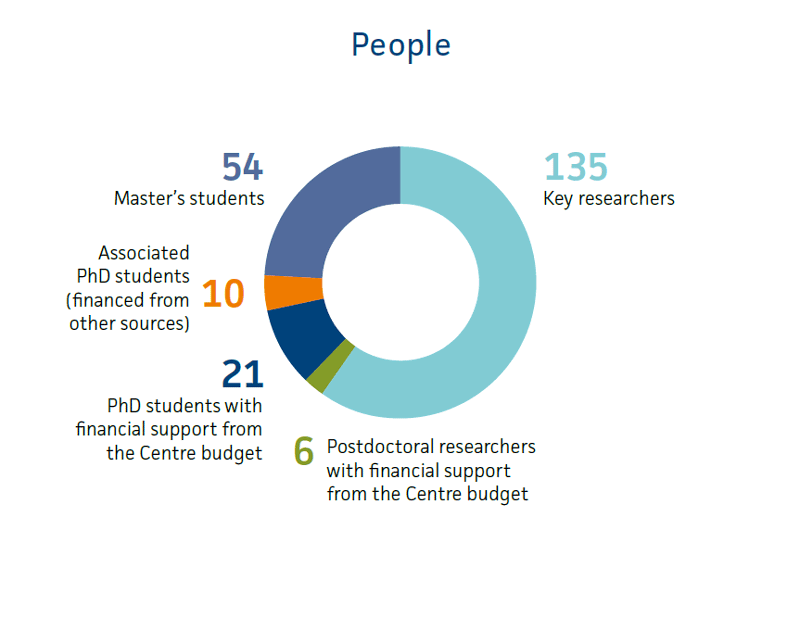

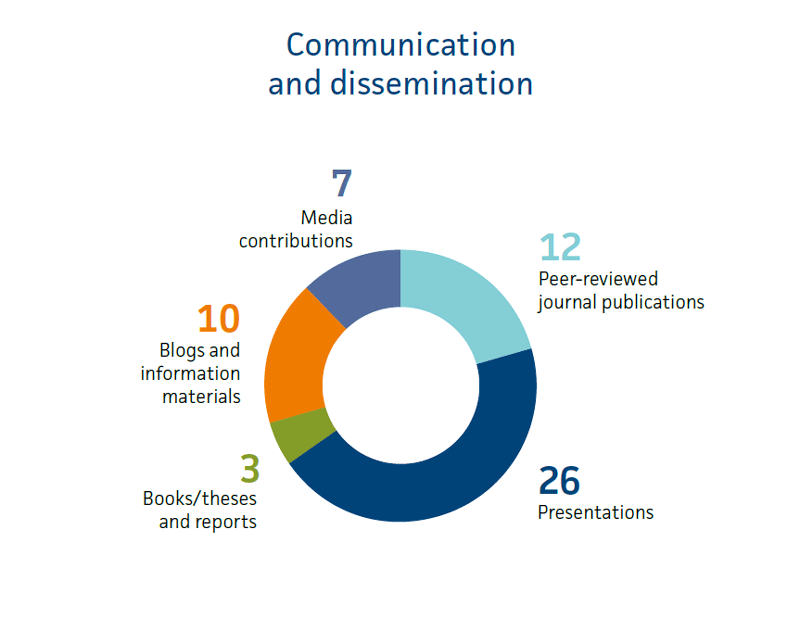

2023 by numbers

Numbers for 2023