About

A summary of our activities

In its eight years of activity, FME HighEFF has driven innovations that have reduced industrial energy consumption and lowered greenhouse gas emissions across a range of industries.

With more than 250 scientific publications, 41 innovation projects, and pioneering pilot implementations ranging from advanced heat pump technologies to modular thermal energy storage solutions, the Centre has not only enhanced Norway’s industrial competitiveness but also positioned its research partners as international leaders. Today, the Centre’s legacy lives on through the HighEFF Innovation Platform, which gathers more than 40 partners across academia and industry.

Key highlights

Contribution to FME’s overarching goals

- 11% reduced specific energy use

- 8% reduced GHG emissions

Research results

- 372 scientific publications

- 41 innovations

- 13 methods and tools

Industrial impact

- 38% electricity savings and 40% CO₂ reduction at the TINE dairy plant

- Handbook and guidelines for excess heat reuse

- Spin-offs like Cartesian, boosting industrial competitiveness

Education & training

- 37 PhDs and postdocs*

- 75 MSc students

- 10 summer internships

*including 12 Associated PhDs

International collaboration

- 40+ partners across three continents

- Active in forums and government consultations

Added value of being a centre

- Access to top research scientists

- Cross-consortium idea exchange

- Webinars, events, Energy Efficiency Conference

- Long-term planning and collaboration

HighEFF: Making Norwegian industry the world’s greenest

HighEFF ambitious goals for development and demonstration of technologies that may improve energy efficiency and reduce emissions from industry.

Energy efficiency measures are to be considered as necessary and enabling for a transition to a low emission society, as presented by the IEA projections to meet the 2-degree target put forward in the Paris agreement. A kWh not used does not have to be produced.

Measures to reduce the energy consumption and emissions from the industry are often less costly than alternative measures. Energy efficiency measures will thus be very important for an optimal transition from a social economic and environmental perspective, and in order to maintain and increase value creation in society.

A kWh not used does not have to be produced.

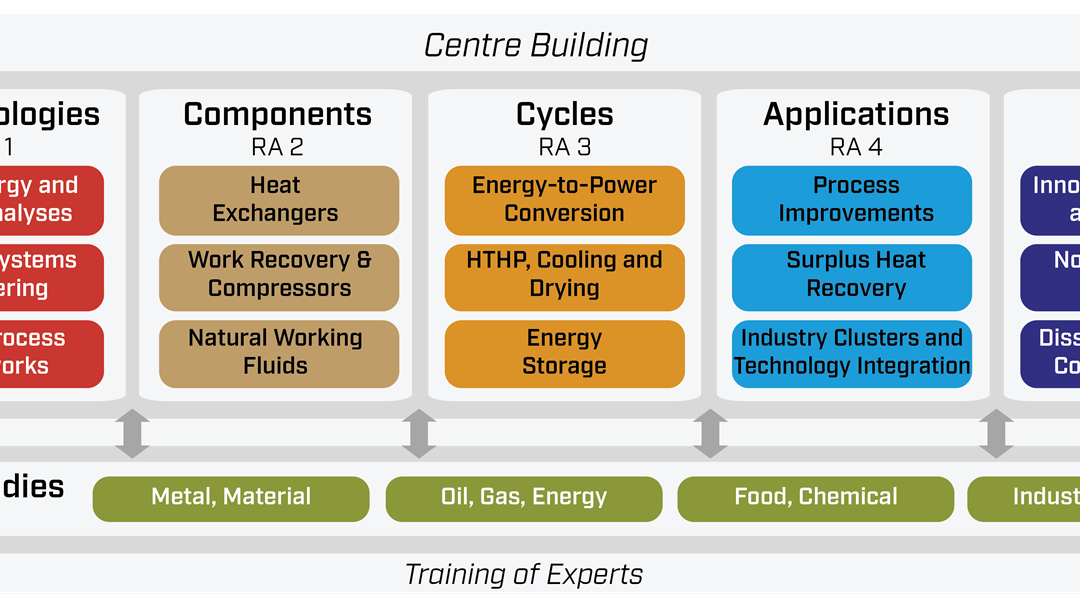

Improved industrial energy efficiency can be achieved by improving the core industrial processes, as well as by capturing and harnessing waste heat and other surplus energy streams, either within the individual industry, or in nearby buildings or industries. In cases where the heat cannot be utilised directly, this may be done by upgrading the heat to a higher temperature level by use of heat pumps or by converting the heat to power. These are tasks that were addressed by FME HighEFF - Centre for an Energy Efficient and Competitive Industry for the Future.

Achievement of the goals

The overall goal of FME HighEFF was: “HighEFF will spearhead the development and commissioning of emerging, energy efficient and cross-sectorial technologies for the industry.”

Original objectives the Centre committed to:

- 20-30 % reduction in specific energy use

- 10 % reduction in greenhouse gas emissions

- 15-20 new innovative solutions

- 6 KPN, 8 IPN, 8 DEMO and 5 EU spin-off projects

- 22 PhD/Post.docs candidates, 50 MSc candidates

- 30 new experts

- 100 journal articles and conference papers

- Internationally leading Centre

Fulfilment of these objectives/KPIs has been measured and updated throughout the Centre period. Status as of Centre completion is given in the infoboxes below. The numbers clearly show that the Centre has delivered very well on most KPIs.

The targets on reduced specific energy use and reduced emissions have been met in the industry sector “Food and Chemical”, but only partly for the sectors “Metals and Materials” and “Oil, Gas and Energy”. Since the latter two sectors are by far the largest in terms of energy use and emissions, the reductions in absolute numbers are significant. It also reflects that these industries have industrial processes developed and refined over years and that the processes are inherently power demanding, with correspondingly large emissions. Currently there is a focus on decarbonisation in these sectors, requiring totally new carbon-free processes or implementation of carbon capture measures. A paradox is that the new processes may lead to higher specific energy use.

🌿 Emission and Energy Reductions

Enable 20–30% reduction in specific energy use and 10% in emissions through implementation of developed technologies and solutions.

- Energy use reduction target: 30 → 11 achieved (overall) 🟡

- Metals and Materials: 9 🟡

- Oil, Gas and Energy: 13 🟡

- Food and Chemicals: 31 🟢

- CO₂ emissions reduction target: 10 → 8 achieved (overall) 🟡

- Metals and Materials: 6 🟡

- Oil, Gas and Energy: 13 🟢

- Food and Chemicals: 42 🟢

💡 Innovation

Value creation through 15–20 new innovative energy-efficient solutions.

Target: 20 → 41 achieved (28 nearly completed) 🟢

🛠️ Methods and Tools

Development of tools for analysis, design, and optimization.

Target: 10 → 13 developed (11 nearly completed) 🟢

🌍 International Status

Goal: Build a leading centre for strategic research on industrial energy efficiency.

Not evaluated yet

🔗 Spin-offs

Goal: Generate KPN, IPN, DEMO and EU projects.

- KPN/KSP: 6 → 11 (33 applications) 🟢

- IPN: 8 → 8 (12 app.) 🟢

- DEMO: 6 → 0 (0 app.) 🔴

- EU: 4 → 4 (10 app.) 🟢

- Other projects: 10 (26 app.) 🟢

🎓 Competence Building & Education

- PhDs & postdocs: 22 → 19 PhDs, 6 postdocs🟢

- Associated PhDs: 10 → 12 🟢

- MSc: 50 → 73 🟢

- Internships: 5 → 10 🟢

- Experts: 30 → 15–20 (estimate) 🟡

📣 Dissemination & Communication

- Journal/Conf. Papers: 150 → 372 🟢

- Presentations: 383 🟢

- Blogs/media: 245 (+ 42 videos) 🟢