Aud Nina Wærnes

Senior Business Developer- Name

- Aud Nina Wærnes

- Title

- Senior Business Developer

- Phone

- +47 93 05 94 28

- Department

- Metal Production and Processing

- Office

- Trondheim

- Company

- SINTEF AS

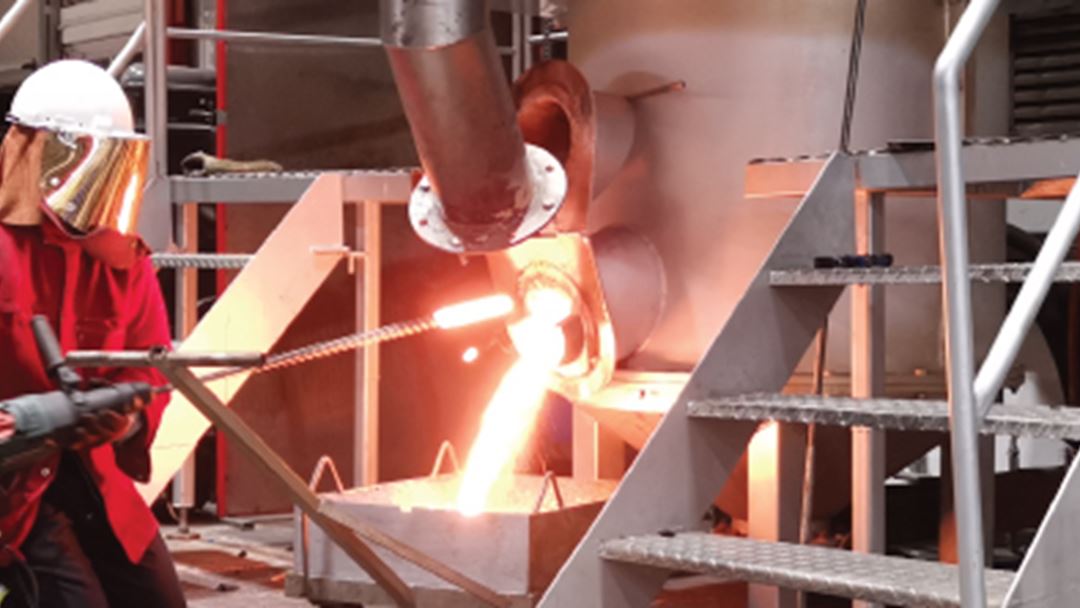

RA4 Applications studied the potential for more energy-efficient processes and improved heat capture and utilisation concepts. The Norwegian metallurgical industries are committed to net zero emissions of CO₂ by 2050. The focus in the short term is to both replace fossil carbon by biogenic carbon, and to carry out CO₂ capture. Novel processes, like electrowinning and hydrogen plasma, are likely to be the solution in the long term. Enabling the recovery of industrial surplus heat with a focus on high utilisation of significant industrial sources is another important priority.

Flue gas recirculation (FGR) can be a tool to increase CO₂ concentration in the off-gas from Si production. Higher CO₂ concentrations in the off-gas reduces the costs of carbon capture and could enable additional CC technologies if increased sufficiently. In the PhD work of Vegar Andersen, FGR was experimentally and theoretically studied to evaluate its effects on the process, including CO₂ concentration in the off-gas, possible future carbon capture technologies and reduced NOx emissions. Small-scale experiments were conducted to investigate the effect of different gas atmospheres on silica fume formation, as well as a larger pilot-scale one to demonstrate the concept in close to industrial conditions. Results show that FGR combined with gas flow control is an efficient way of increasing the CO₂ concentration in the off-gas, without increasing off-gas temperature.

The emission of Polycyclic Aromatic Hydrocarbons (PAH) from processes (especially related to metal processing and production industries) is considered to originate from the combustion of the carbon materials in furnaces that contain PAH and aliphatic fuels. The use of detailed Computational Fluid Dynamics (CFD) simulations to predict PAH emissions from industrial processes is impractical due to the very high computational overhead, and to the relatively high uncertainty in the input data. To address this, a post-processing approach was developed to predict PAH evolution which uses the results of the CFD simulation of the major process gases based on a relevant skeletal mechanism as the input to PSR reactors using detailed PAH chemistry. Results show that the proposed approach can predict the PAH emission, at a reasonable accuracy and a fraction of computational cost.

Improved prereduction of manganese ores leads to reduced energy and carbon consumption in production of manganese ferroalloys. Variations in energy efficiency in manganese-furnaces occur due to variations in the prereduction zone, the upper part of the furnace. Optimisation of prereduction requires that the behaviour of manganese ores and the factors influencing the kinetics are understood. Two commercial manganese ores were studied by PhD Trine A. Larssen. Variables included particle size, gas composition, heating rate and temperature.

Optimising prereduction includes adjusting particle size distribution and exploring pretreatment methods, such as using off-gas from the submerged arc furnace for prereduction. This approach can reduce the carbon and energy-intensive Boudouard reaction and was a key focus of the EU H2020 PreMa project, a HighEFF spinoff.

The Norwegian industry produces approximately 20 TWh of excess heat every year, where the aluminium industry is the largest producer of low temperature excess heat (below 250°C). The off-gas from aluminium electrolysis is a significant source of surplus heat that is currently unused. To enable utilisation of this surplus heat, the industry requires cost- and space-efficient heat exchangers that can withstand the challenging conditions in the off-gas channels.

A prototype of the novel heat exchange concept that has been developed for aluminium smelter off-gas during the last years, was built and transported to the Alcoa plant in Mosjøen, which will serve as a test centre. All the equipment i.e. the heat exchanger, sensors and fittings, logging system and electronics are in Mosjøen, waiting to be installed. Plans for startup and further continuation are being discussed but will not be finalised within the framework of FME HighEFF.

Circular economy and industrial symbiosis are gaining momentum as pathways towards a low-carbon and energy-efficient society. Industry networks and clusters are viewed as key instruments to promote these strategies.

Measuring industry's impact on nature is no easy task, but it must be done if we want to meet the UN's biodiversity targets. The past few years have been marked by several global crises, but despite that, environmental related risks like climate change, biodiversity loss and ecosystem collapse remain at the top of the list of global risks in a 10-years perspective. Most industries focus their efforts only on reducing climate change (through reduction of CO₂ emissions) and on some types of pollution. In this context, systems for emission accounting and reporting are already in place for most of the industrial sectors. However, there is currently no widespread system for assessing and monitoring the impact of land use and direct exploitation, which are together responsible for over 50 % of the decline in nature. HighEFF has summarised which KPIs for measuring impact on biodiversity and natural systems already exist, which of them are most suited for industries, and what has already been done to reduce ongoing industry developments’ impact on nature.

Silicon (Si) is produced by carbothermal reduction of quartz to Si, using carbon reductants, which are a source of CO₂ emissions. Although there have been initiatives for finding alternative carbon-neutral processes, it is still the carbothermal route that dominates the industry, and hence, the process must be modified to achieve emission reductions. Out of several proposed alterations of the conventional production process, retrofitting post-combustion carbon capture (PCC) to Si smelters is increasingly receiving attention. Flue gas recirculation (FGR) could in this sense be a tool to increase CO₂ concentration in the off-gas from Si production. Higher CO₂ concentrations in the off-gas reduces the costs of carbon capture and could also enable additional CC technologies if increased sufficiently. In the PhD work of Vegard Andersen, FGR has been experimentally and theoretically studied to evaluate its effects on the process, including CO₂ concentration in the off-gas, possible future carbon capture technologies and reduced NOx emissions. This has been done through mass and energy modelling of the Si process and a coupled carbon capture process. Small-scale experiments have been conducted to investigate the effect of different gas atmospheres on silica fume formation. A larger pilot-scale experiment of FGR for silicon production has also been conducted, demonstrating the concept in close to industrial conditions. Combustion of the process gases SiO and CO in the tapping gas has also been studied on an industrial scale during a measurement campaign on a large silicon furnace.

Modelling the Si process showed that FGR is an efficient way of increasing the CO₂ concentration in the off-gas, with the benefit of not increasing off-gas temperature. The cost of carbon capture in a conventional scrubber stripper setup was found to be reduced with increasing FGR as higher CO₂ off-gas concentrations allowed for more efficient capture with smaller components and a lower solvent flow, leading to lower specific energy consumption.

Small-scale experiments of SiO combustion in different atmospheres indicated that replacing O₂ in the combustion air with CO₂ had an insignificant impact on silica fume morphology. However, expanding the combustion of SiO gas from a small-scale to a pilot-scale test resulted in indications that the specific surface area of the silica fume increases with increasing FGR. The pilot-scale experiment was also a successful demonstration of how CO₂ concentrations could be increased to over 20 vol % and with reduced specific NOx emissions, although not as significantly as previously predicted by modelling. During the tapping gas measurement campaign, inert gas injection in the tapping gas intended to suppress NOx formation was performed but was not successful. NOx generation was however found to be more strongly correlated to the energy added to the tapping gas stream than to the amount of SiO combustion, as previously assumed. It was observed that particulate matter (PM) formed from the oxidation of liquid Si did not generate NOx to the same extent as the combustion of SiO gas directly from the taphole. Process crater temperatures were estimated to be in the range of 1890 to 2200°C, using the concentration of PM and CO₂ in the tapping gas.

A report has been finished on 1D flame model applied to the study of chemistry in silicon furnaces: Gas-phase chemistry and approximate treatments of gas-solid reactions.

The emission of Polycyclic Aromatic Hydrocarbons (PAH) from processes (especially related to metal processing and production industries) is considered to originate from the combustion of the carbon materials in furnaces that contain PAH and aliphatic fuels. The use of detailed CFD simulations to predict PAH emissions from industrial processes is impractical due to the very high computational overhead, and to the relatively high uncertainty in the input data. To address this, a post processing approach is proposed to predict PAH evolution which uses the results of the CFD simulation of the major process gases based on a relevant skeletal mechanism as the input to PSR reactors using detailed PAH chemistry. Our report describes the underlying assumptions of the proposed approach and its implementation. The prediction from the proposed approach is compared with results of CFD simulation employing detailed PAH chemistry for the case of a co-flow burner burning a mixture of C₂H₂ and H₂ at various flue gas recycling levels and fuel inlet velocities. The results show that the proposed approach can predict the PAH emission, at a reasonable accuracy and a fraction of computational cost, using an appropriate value of the tuning parameter used in the definition of the residence time of the PSR model.

The experimental work on understanding internal energy distribution inside Manganese-alloy furnaces has continued in 2023. The activity started with the PhD work of Trine A. Larsen. A knowledge gap was identified previously; a challenge which will become more critical as the industry switches to more biocarbon to replace fossil carbon. Therefore, the focus has been to investigate if the volatiles that evolve from biocarbon behave differently from those that evolve from traditional fossil carbon, and how it influences the prereduction of manganese ores. Previous experiments have shown that the presence of biocarbon improves prereduction when reduced without an external gas flow, and this has been attributed to the presence of volatiles. Two summer interns have participated in the experimental work where different manganese ores were reduced in the presence of biocarbon, fossil carbon or no carbon. The experiments in this work were done with an external gas flow of CO/CO₂ to more closely simulate real furnace conditions. With the presence of an external reducing gas flow, the characteristics of the carbon were of less importance to the reduction rate of the ores, particularly at low temperatures. This indicates that the positive effect of biocarbon on prereduction due to volatiles may be less significant in a real furnace than previous experiments have indicated.

The Norwegian industry produces approximately 20 TWh of excess heat every year, where the aluminium industry is the largest producer of low temperature excess heat (below 250°C). The off-gas from aluminium electrolysis is a significant source of surplus heat that is currently unused. In order to enable utilisation of this surplus heat, the industry requires cost- and space-efficient heat exchangers that can withstand the challenging conditions in the off-gas channels.

A prototype of the novel heat exchange concept that has been developed for aluminium smelter off-gas during the last years has now been built. The plan for the rest of the Centre period is to test its performance at an industrial site. The test location that has been identified is the Alcoa plant in Mosjøen. The site has been inspected and discussion with the relevant personnel at the site has been initiated to identify what steps need to be taken to prepare for the installation and testing of the prototype heat exchanger. One of the first steps was to design a cooling system that allows to remove the heat captured by the heat exchanger. The heat exchanger was also further modified to install a window to allow for internal inspection.

The activity on knowledge building and spreading on the topic of surplus heat utilisation is also continuing, and the goal during the last part of the Centre is to summarise the activities on the topic in both a popular science and an academic article. The work is in progress in collaboration with WP 3.1. As a first step, a blog article has been published on SINTEF Blog with the title “How to get from knowledge building on surplus heat recovery to practical and attractive demonstrators?”

Circular economy and industrial symbiosis are gaining momentum as pathways towards a low-carbon and energy-efficient society. Industry networks and clusters are viewed as key instruments to promote these strategies, and in 2023 we have investigated three different topics:

Potential for synergies between metal and food industries at Orkdal by producing microalgae: Sustainable fish feed is becoming increasingly more important. In this task, the production of microalgae, one of the possibilities of sustainable feed, has been investigated. The work will be continued in 2024 with the aim of giving a potential for how much carbon dioxide and excess heat can be utilised to produce microalgae, as well as an overall assessment of production feasibility.

Heat integration at industrial parks: To satisfy the increasing demand for cooling water in Mo Industrial Park, one could reuse dirty cooling water from smolt production. Kvarøy Smolt already utilises dirty water for heat recovery. In this task, the operation of the existing plate heat exchangers was evaluated using a heat exchanger model described in MS Excel. Relatively high UA-values were calculated, and the heat exchangers are therefore considered to be functioning well. This indicates that plate heat exchangers are suitable for use with dirty water and that the current chemical cleaning is sufficient. The Excel model was also used to evaluate a case where the dirty water from Kvarøy Smolt is used to cool a planned hydrogen production plant. Only around 10% of the wastewater from Kvarøy Smolt's heat exchangers would have to be used to achieve the planned cooling capacity. Use of dirty cooling water will increase both the investment costs and operational costs for the heat exchangers.

Green and blue KPIs for industries: Until now, HighEFF has focused on KPIs related to reduced emissions and specific energy use. Loss of biodiversity and use of land are, however, at least as important, if not more. A lot of land-intensive industry is expected to be built in Norway in the coming years (e.g., battery factories, land-based farming, data centres). Similarly, there are also industrial activities planned in the oceans (e.g., wind farms, macro-algae production).

Among other international initiatives, the Taskforce on Nature-related Financial Disclosures has been working on defining KPIs that can give indications on the impact that industrial activities have on nature. These KPIs have been collected, summarised and exemplified in a memo, with the goal of further learning on the importance and potential of sustainability metrics as well as inform HighEFF partners about the importance of the topic. The preliminary results from this work were presented in May at HighEFF’s Annual Consortium Meeting. The work on this topic will be further finalised and disseminated through a blog article in 2024.

An important activity has been the recycling of off-gas from silicon/ferrosilicon-furnaces, to increase the CO₂ content of the off-gas and make CO₂ capture easier. This is a continuation of the work done in 2021.

Off-gas recycling also influences the gas-phase chemistry in other ways such as PAH (polycyclic aromatic hydrocarbons) emission. Controlling PAH emissions is important for the industry, so it is necessary to establish how any new process or process modification influences PAH formation and oxidation. SINTEF Industry developed kinetic methods for PAH formation and PAH oxidation based on a chemical reactor network (CRN) approach to be used in post-processing of CFD (computational fluid dynamics) models to model the formation, oxidation and distribution of PAH during gas recycling.

Gas recycling may also indirectly influence the conditions below the charge surface of the furnace. Changes in silicon monoxide (SiO) gas condensation will mean a change in how much SiO-gas leaves the charge surface (influencing Si-yield), and the concentration of SiO-gas that enters the combustion zone (influencing amount and possibly also quality of micro silica produced). SINTEF Industry are looking at how this influences the conditions for SiO-gas condensation, by modelling the kinetics of relevant reactions.

Variations in energy efficiency in Mn-furnaces occur due to variations in the prereduction zone. Ferromanganese prereduction mechanisms have been studied previously at HighEFF by PhD-candidate Trine Larssen. She has also gone through the large amounts of experimental data that have been produced over the years, as well as several models, and evaluated them for consistency and general applicability. A knowledge gap that was identified and which will only become ever more critical as the industry switches to more bio-carbon is the effect of volatiles on prereduction. Experimental work started in 2022 on this task and will continue in 2023. Eramet Manganese Norway and Eramet Ideas in France are closely involved, serving in an advisory capacity for this project.

The Norwegian industry produces approximately 20 TWh of excess heat every year, where the aluminium industry is the largest producer of low temperature excess heat (below 250°C). The off-gas from aluminium electrolysis is a significant source of surplus heat that is currently unused. In order to enable utilisation of this surplus heat, the industry requires cost- and space-efficient heat exchangers that can withstand the challenging conditions in the off-gas channels.

At HighEFF, we have explored a modified plate-type heat exchanger concept without fins on the gas-side for this purpose. This work has continued in 2022. A supplier capable of constructing this prototype has been found. Material testing for aluminium has successfully been performed at Hydro Sunndal, and measurements of cooling water pressure drop through a heat exchanger plate have been performed at the SINTEF laboratories. The prototype design has been revised in conversation with the supplier M-tech, and a detailed site analysis has been performed together with Alcoa to ensure compatibility. Preliminary plans for a final test setup have been made.

HighEFF organised a workshop on the topic "Competitive surplus heat recovery – how to get from knowledge building to practical and attractive demonstrators". The workshop included both academic and industrial viewpoints to energy recovery and conversion and had the goal of being an arena for mutual learning and discussions. The meeting aimed at targeting topics that have general applicability in terms of industry relevance and focused on what are the types of external use we should recover heat for, and how to get to a demo system.

Circular economy and industrial symbiosis are gaining momentum as pathways towards a low-carbon and energy-efficient society. Industry networks and clusters are viewed as key instruments to promote these strategies, and we have investigated policy mechanisms, funding schemes and facilitation attempts to orchestrate their development.

The work on industry clusters in WP4.3 was conducted in close collaboration with WP5.1 (barriers, enablers, and innovation). Together, these WPs have gathered an extensive database of existing clusters and surplus heat exchange and significantly improved our knowledge on innovation challenges, enablers, organisational models, and local factors promoting energy efficiency improvements.

With the social science work in RA4 drawing to a close, we focused in 2022 on direct dissemination of results and outreach activities to clusters and industrial actors within and outside of HighEFF. This was done both to widen the impact of research results, but also to collect best-practices and novel insights useful for HighEFF partners and stimulate to collaboration and innovation. These activities include bilateral meetings, conference attendance, HighEFF workshops, and presentations as invited speakers in related projects.

An important activity has been the recycling of off-gas from silicon/ferrosilicon-furnaces, to increase the CO₂ content of the off -gas and make CO₂ capture easier. A highlight of this activity in 2021 has been the PhD work of Vegar Andersen and the 80-hour long pilot experiment he organised and ran in a collaboration between HighEFF and several other projects at NTNU/SINTEF.

Off-gas recycling also influences the gas- phase chemistry in other ways such as PAH emission. Controlling PAH-emissions is important for the industry, so it is necessary to establish how any new process or process modifi cation influences PAH formation and oxidation SINTEF Industry developed kinetic methods for PAH-formation and PAH-oxidation based on a chemical reactor network (CRN) approach to be used in post-processing of CFD-models to model the formation, oxidation and distribution of PAH during gas recycling.

Gas-recycling may also indirectly influence the conditions below the charge surface of the furnace. Changes in SiO-gas condensation will mean a change in how much SiO-gas leaves the charge surface (influencing Si-yield), and the concentration of SiO-gas that enters the combustion zone (influencing amount and possibly also quality of micro silica produced). SINTEF Industry are looking at how this influences the conditions for SiO-gas condensation, by modelling the kinetics of relevant reactions.

An important motivation for the recycling of off -gas is the potential to capture and store/utilise the CO₂. As part of the HighEFF New Emerging Concepts (NEC) project INTERCUR, "A mixed integer linear model for optimising material and energy flows in industrial clusters" was developed. The INTERCUR-model represents a general framework for decision support in the design of industrial clusters, but also presents some potential for application to a single plant. The possibility of using the INTERCUR-model to optimise energy use in a ferroalloys plant incorporating CCS has been briefly outlined in WP4 1.

Variations in energy efficiency in Mn-furnaces occur due to variations in the prereduction zone. Ferromanganese prereduction mechanisms have been studied previously in HighEFF by PhD-candidate Trine Larssen Large amounts of experimental data have been produced over the years, as well as several models. This data and models are being evaluated for consistency and general applicability of results Gaps are being identified that need to be filled with further models or experimental data It is expected that experimental work will start within this task in 2022

The Norwegian industry produces approximately 20 TWh of excess heat every year, where the aluminium industry is the largest producer of low temperature excess heat (below 250°C). The off-gas from aluminium electrolysis is a significant source of surplus heat that is currently unused. In order to possible utilise this surplus heat, the industry requires cost- and space-efficient heat exchangers that can withstand the challenging conditions in the off-gas channels. In HighEFF, we have explored a modified plate-type heat exchanger concept without fins on the gas-side for this purpose. New developments in the in-house heat exchanger modelling software at SINTEF Energy Research have made it possible to study any type of heat exchanger geometry. This improved model was used in 2021 to design a prototype for a heat exchanger to be tested for aluminium electrolysis off-gas. This was based on the plate-no-fin concept developed at HighEFF, and the goal is to eventually validate its proposed resistance to scale formation. The proposed test site and the accompanying constraints were taken into consideration in the development of the design of the prototype.

High-EFF PhD student Mandar Thombre defended his PhD in 2021. His PhD work was titled “Novel Approaches in Robust Multistage Nonlinear Model Predictive Control”. The work focuses on developing data-based methods for scenario selection, and on sensitivity-based methods for faster solution of large-scale optimisation problems that arise in model predictive control. Industrial data from our HighEFF partner Mo industry park was used to develop a realistic case study on energy storage.

The off-gas from the silicon furnace has a very low concentration of CO2, which makes its capture difficult and expensive. By recycling parts of the off-gas back into the furnace, it is possible to raise the CO2- concentrations to higher levels. HighEFF has explored this from a theoretical point of view, and the work has continued in 2020. Models show that NOx formation is suppressed under conditions of flue-gas recycle. PhD-student Vegar Andersen started in 2020 and will perform experiments investigating the effect of flue-gas recycle on microsilica-formation. Theoretical work from HighEFF has been instrumental in the design of a pilot-scale experiment that will be run in 2021 in a collaboration between several projects.

There are several different technologies available for CO2 capture, which have different advantages and disadvantages relating to working concentrations of CO2, energy demands and others. A review of existing technologies has been performed to answer the request from industry to look at an evaluation of capture and utilisation of energy from metallurgical furnaces in a system where one of the energy outputs is towards CO2 capture (e.g. amine regeneration), and the ultimate goal is an optimisation of the use of the recovered energy between electricity generation, CO2-capture, district heating, etc.

Another highlight of the year is the dissemination of PhD candidate Trine A Larssen, on the topic of "Prereduction of Comilog- and Nchwaning ore".

The off-gas from aluminium electrolysis is a significant source of surplus heat that is currently unused. Increased energy efficiency in this industry can be an important contribution to reducing the environmental footprint of the aluminium product. In order to make such investments, the industry requires cost- and space-efficient heat exchangers that can withstand the challenging conditions in the off-gas channels. In HighEFF, we have explored a modified plate-type heat exchanger concept without fins on the gasside for this purpose. Previous simulations showed that this concept can be competitive both in terms of installation cost and compactness, which led to a conference paper and presentation at the Rankine 2020 Conference.

New developments in the in-house heat exchanger modelling software at SINTEF Energy Research have made it possible to study any type of heat exchanger geometry. This improved model was in 2020 used to further investigate the "plate-no-fin" concept for aluminium smelter off-gas. We explored two different unconventional, non-constant geometries and showed that the heat exchanger weight can be further reduced at the expense of increased pressure drop. This trade-off between installation and operational cost will be further explored next year.

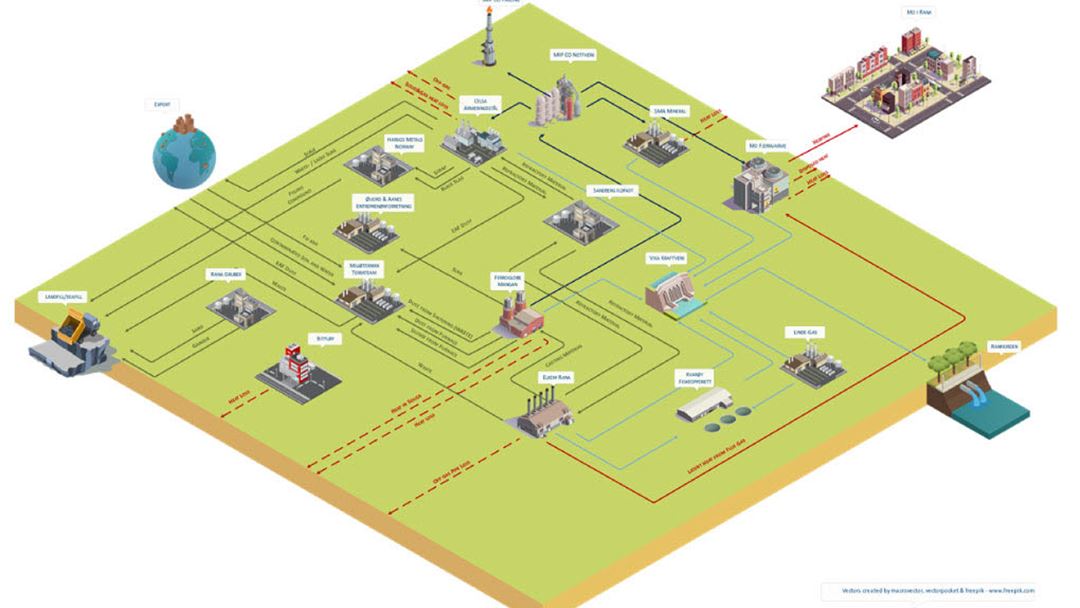

An interactive tool for visualising energy and material flows in an industrial cluster was created by a summer intern, NTNU-student Cosmin Aron. The work was supervised by researchers from the three SINTEF institutes Industry, Energy and Helgeland. The tool can be used for in-depth analysis of current synergies and by-product utilisation in an industrial cluster, as well as for improvements and integration of new actors. It can also be useful for communication and promoting sustainability and good practices. It combines the simplicity of a diagram with more layers of information added through interactivity.

The model was designed in Microsoft Visio and exported as an interactive webpage, with all the displayed data being imported from an external source (an Excel-file). The tool was applied for visualising the energy and material flows at Mo Industripark (MIP), as shown below.

The primary focus is on process improvements within ferroalloys. Recovery of surplus heat has a focus on high utilisation of significant industrial sources. With an existing industry park as a scenario, the potential of "green" industry clusters and local thermal grids on a Nordic scale are developed.

Work on efficient energy recovery from flue gases from smelters has been continued, and concepts for energy cascading were developed in 2019. These concepts have been presented to the industry and show potential for energy integration across industries.

The potential includes combined electricity recovery by Combined Heat & Power (CHP)-systems, biocarbon and biochemical production, integration towards carbon capture and storage (CCS) and at the lowest temperature ranges fish nurseries and green houses. The conceptual integration potential is large, the obstacles are more on the organizational level.

Modelling of the Submerged Arc Furnace (SAF) process has been studied for several decades. However, few of these models are integrated and show/represent the entire "picture" of the furnace. Initially a review of the work performed within The Norwegian Ferroalloy Producers Research Association (FFF)-companies has been performed to systematize the information available and start work to develop an understanding of the gaps. Two workshops with strong industrial involvement have been arranged. The results are compiled to form a basis for a Roadmap which shows the needs for further development of models. The models shall be used to improve the understanding of the mechanisms inside a furnace and how to influence/control it to minimize energy and carbon consumption, which in turn leads to cost savings.

Investigation of a novel heat exchanger concept for aluminium smelter off-gas was a key activity in 2019. By drawing inspiration from clean gas heat exchangers, a modified plate-type concept without fins on the gas side was developed. We hypothesize that such a concept can efficiently recover energy from the off-gas while simultaneously being able to avoid problems with scale formation, which will be important in order to avoid increased operational costs. Detailed heat exchanger simulations were performed, and results were compared to a clean gas reference exchanger. Results indicate that the developed concept can be competitive both in terms of weight and compactness compared to the reference case. Reduced weight will give lower capital costs and compactness is important because available space is often limited at aluminium plants. Increasing energy efficiency in the industry will be a key step towards reaching our climate ambitions. We will continue developing the plate-type concept in 2020.

Transferring knowledge to industry and sharing knowledge between academic and industrial partners is key for HighEFF to maximise its impact. In collaboration with the work package on energy-to-power conversion, a seminar entitled "Practical vs. Academic approach to Energy Recovery" was held within the Energy Recovery reference group. The seminar was well attended by both research and industry partners from HighEFF. Elkem and Finnfjord shared their practical experiences with operating industrial ferroalloy furnace off-gas energy recovery systems, and researchers from NTNU and SINTEF presented on improvement potentials, alternative technologies, novel ideas and concepts. In addition, Alcoa, Alfa Laval, Equinor, Eramet, GE Power, Hydro and KTH were present at the meeting. The workshop facilitated good disussions between researchers and industry and new potential topics for collaboration were identified.

A methodology for optimal Thermal Energy Storage (TES) tank dimensioning as well as an operation strategy for improved utilization of waste heat for district heating have been developed, in close collaboration with Mo Industripark/Mo Fjernvarme. The objective of the study has been to find an optimal TES size that minimizes investment costs while maximizing savings of peak heating costs, taking into account the actual dynamics of the heat central and impact of optimal control of the TES at the time of investment decision. The proposed methodology enables MFV to evaluate the potential economic, environmental and energy savings of TES relative to the investment costs.

Energy consumption and potential energy savings in power intensive industries such as ferro-alloy industries where the prime energy consumer is the submerged arc furnace (SAF) and potential reduction and/or use of energy recovered were the main activities in 2018. A literature review on auxiliary systems in ferro-alloy production processes with respect to reduced energy consumption, covers e.g. the utilization of the energy streams exiting the SAF through the furnace off-gases. Concepts for a cascading utilization of the energy in the temperature range from 800°C to approximately 150°C have been presented.

Starting from the energy cascading concept, a new task has been initiated to simultaneously reduce overall energy consumption, NOx-reduction and potentially facilitate CO2-capture from ferro-silicon furnaces. Currently, furnaces utilize fresh air for temperature control in the furnace hood, during the initial study a concept is developed where cleaned flue gas after energy recovery is recycled to the furnace, the study consist of (i) a CFD-model to evaluate the influence on the temperature profile in the furnace hood and thus NOx-formation and (ii) an evaluation of the potential energy savings and energy recovery through an improved temperature control which allows for higher temperatures into the energy recovery system.

In total three reports/papers on the technical and economical feasibility of simultaneously energy recovery and emission reduction have been presented linking activities within EnergiX-project "SCORE" to HighEFF. Two papers at Infacon considering the design and experimental verification of the SCORE concept; followed up by a technical and economical evaluation at SPIS/Flogen 2018.

The energy flow database was completed for Alcoa, Eramet, Hydro and Wacker's plants in Norway. The data provided by the industry partners was validated through mass and energy balances both on plant and sub-process level, revealing significant variations in the data quality. Exergy calculations were performed for some plants for additional validation. Process flow diagrams giving an overview of mass and energy flows as well as data validation have been completed for a selection of the plants. The diagrams and the database itself are available on the HighEFF eRoom.

A possible path for improving Al smelter off-gas heat exchanger design was explored. It was investigated whether changing tube geometry into a wavy cross-section would improve heat exchanger performance. Results were compared against the current state-of-the-art, showing both advantages and disadvantages.

A methodology for modelling and optimization of energy exchange in industrial clusters and dynamic mathematical models for simultaneous exchange of energy and materials were developed. The description of barriers, whether they are physical, conceptual, technical or cultural, and understanding how thesecan be overcome are crucial in order to identify and implement future cross-industrial synergies and current activities will thus be extended to 2019.

A comprehensive literature review has been made on finalized and on-going projects within The Norwegian Ferroalloy Producers Research Association (FFF) with respect to energy recovery. Processes with high potential for energy recovery (in terms of energy quality and quantity) are identified and selected for further analysis together with the industry. Recycling of flue gas into ferroalloy furnaces is the first activity.

A report/paper on the technical and economical feasibility of simultaneously energy recovery and emission reduction has been made by linking activities within EnergiX-project "SCORE" to HighEFF. Two papers are prepared: 1) Experimental verification and operation presented at Infacon 2018, 2) a technical and economical evaluation submitted to SPIS/Flogen 2018.

The framework for the database of thermodynamic potential in surplus heat sources has been developed, with extended scope compared to the initial idea. Work on data acquisition has begun for the metals and materials sector. So far, data from Alcoa, Hydro, Wacker Chemical, Eramet, and Elkem have been received.

The initial activity on "surplus heat database" has been tentatively extended to "Energy flow database", to also include energy and material input streams for each subprocess in the industry plants. This should enable the database to be useful for various activities in many RA's and WP's in HighEFF. Completed entries for individual plants in the "Energy flow database" has been presented as process flow diagrams showing energy and materials flows. Several site visits were arranged to observe authentic plant scenarios and conditions, and scrutinize the energy flow data on-site.

A Modelica-based modelling and optimization framework for coordinated exchange of surplus heat in industry clusters has been developed. Preliminary results have illustrated both advantages and challenges of using optimization-based control and intermediate storage as a means of leveraging varying surplus-heat streams and demands to improve utilization of surplus heat in industry clusters.