Trond Andresen

Senior Research Scientist- Name

- Trond Andresen

- Title

- Senior Research Scientist

- Phone

- +47 91 57 43 80

- Department

- Gas Technology

- Office

- Trondheim

- Company

- SINTEF Energi AS

Cycles RA3 studied and developed technologies and cycles for thermal energy conversion and storage; with main focus on heat pumping, heat-to-power conversion, and thermal energy storage. The research covers technologies on process, plant, or local grid level. “RA3 Cycles” is thematically positioned in the middle of the Centre structure, where it has applied methods and building blocks developed by RA1 and RA2, and in turn developed cycles and processes to be put into use in industrial applications and case studies (RA4-RA6).

RA3 topics frequently deal with upgrading or transferring surplus heat in some form, to allow for reutilisation. A general finding from our work is the significance of “lifting the gaze” when it comes to actions to improve industrial energy efficiency. No amount of technology optimisation can make up for already wasted thermodynamic potential. The best energy efficiency measures are usually not something that can be added on top of an existing process, but rather a more integrated optimisation of (part of) the entire system. The highest potential can be found when core processes are fully integrated with energy recovery and thermal energy supply. This change in perspective is visible in HighEFF work and results over the Centre duration.

Initial studies considered non-integrated cases ofenergy recovery applied to typical conditions found in current industries processes. The system impact from energy recovery was clearly quantifiable, however the calculated benefit was often quite moderate. Later studies evolved around larger-scope integrated process development where energy recovery was just one element. The overall benefit was then typically found to be much larger, however the total fraction of energy and emission reductions that could be accredited to energy efficiency measures was less straightforward to calculate. A general observation in core process developments across HighEFF has been that thermal control (heat extraction) is typically required in order for the new process to function, and that the temperature levels and thereby the potential for energy recovery is higher in these new processes.

Thermal Energy Storage (TES) as a research topic evolved considerably over the Centre duration. TES alone does not directly reduce energy consumption of connected processes; however, it enables improvements on process, plant, and even grid level, by decoupling of energy inputs and outputs, and thus reducing peak load of external supply. This has become increasingly important with the growing pressure on power grids, and increasing variability in electricity prices on both hourly, diurnal and seasonal timeframes. Many promising applications were found, including energy recovery from highly fluctuating industrial excess heat sources for district heating or heat-to-power conversion, and as an enabler for electrification of fossil-based steam production systems with electric boilers or heat pump solutions. Developments on technology includes a novel cold TES technology for peak shaving in food industries, exploration of new storage materials, steam storage integration for improving steam energy recovery systems in smelting plants, and digital tools for optimising TES technology and size to given applications. HighEFF contributed our accumulated knowledge to a white paper on industrial thermal energy storage, together with other internationally leading research institutions.

High Temperature Heat Pump (HTHP) is one key technology where HighEFF research has had a great success and impact. Centre activities, and later spin-off projects, have built up lab infrastructure to demonstrate concepts that push the boundaries of what can be achieved with a range of natural working fluids. This has bridged the gap between research and industry and enabled the realisation of several industrial pilots, proving to end users that the technology works, and supporting HTHP suppliers in developing market-ready systems. HighEFF research and technology developments is well represented in international reference documents, such as the HTHP white paper or the task reports from IEA Annex 58. The future of HTHP beyond HighEFF is looking bright. Even though there has not yet been a massive deployment of new systems, industrial interest and increased focus on energy efficiency is high, and several full scale demonstrators with heat delivery temperatures in the range of 120-160 °C have been put in operation – which was neither technically developed nor broadly recognised as a possibility in the industry prior to the start of HighEFF.

RA3 achieved tremendous expertise and knowledge building during the 8-year duration, performing a wide range of development and evaluation of technologies and concepts important to the 2030 society and beyond.

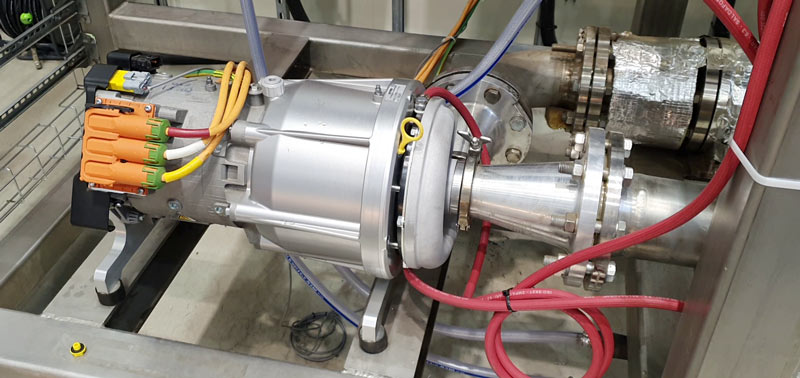

Heating demands in the Norwegian industry are still to a large degree covered via fossil fuel sources, such as natural gas or oil, or using inefficient electric heaters and boilers. At the same time, the same heat-intensive industries generate a significant amount of waste heat which could be upgraded and re-used back into the process using High-Temperature Heat Pumps (HTHPs). HTHPs will therefore significantly contribute to reducing industrial emissions, but also to improving energy efficiency through utilisation of waste heat, and to reducing the load on the electrical grid. HighEFF, in collaboration with the EU project FRIENDSHIP, is currently developing and experimenting with HTHP cycles to cover industrial heating demand up to 200 °C based on compact high-speed steam turbo-compressors.

Water/Steam (R718) is an excellent natural refrigerant in many ways: It is cheap and readily available; It is one of the few natural refrigerants which can achieve condensation temperatures of 200°C or more, which means that it is very suitable industrial processes which require steam supply at 10-20 bar; It can be compressed to supply steam directly to the process in an open heat pump cycle, also known as Mechanical Vapor Recompression (MVR). Moreover, unlike synthetic refrigerants, water has no detrimental effects on the climate and the environment. Since it is neither toxic nor flammable, it is very convenient to handle compared to other natural refrigerants used in heat pumps, such as hydrocarbons or ammonia.

In a HTHP, the compressor is the critical component, and one of the main technical barriers is to qualify the compressor to operate reliably at very high temperatures. With heat supply at 180-200°C, the compressor discharge temperatures can be up to 300°C or above. At such high temperatures, it is an advantage to have oil-free compression, since high temperatures degrades the lubricating properties of the oil. Therefore, electrically-driven high-speed centrifugal compressors, also known as turbo-compressors, have been chosen.

Experimental work to characterise the compressors and map their performance is now underway. Turbo-compressors have limited pressure and temperature increase per stage compared to positive displacement compressors. Therefore, a set of two turbo-compressors are installed in series as a two-stage system, in order to maximise the final pressure and temperature of the system. The compressors have been tested up to impeller speeds of 72.000 rpm. Each stage has achieved a pressure ratio of 2.2, with maximum isentropic efficiency of 0.7. The maximum achieved discharge pressure from the stage-2 compressor is 5.25 bara, which corresponds to a steam condensation temperature of 154°C. The maximum thermal capacity of the system is around 700-800 kW. Another great benefit of this compressor type is its compactness. The whole system including the compressor, gearbox and motor is only 70 cm long and weighs less than 80 kg. The experimental work will continue to map the performance of the system up to condensing temperatures of 180-200°C.

Norwegian metal production is an important industry sector with very considerable energy demands. Therefore, increasing the energy efficiency of metal production can have a large impact on overall industrial energy consumption in Norway. Energy efficiency in the metal industry has been studied from several angles already within HighEFF. In 2023, a new study building on previous HighEFF work on aluminium electrolysis has been performed – aiming to quantify the impact on practical heat recovery potential of possible changes to the core process in aluminium plants of the future.

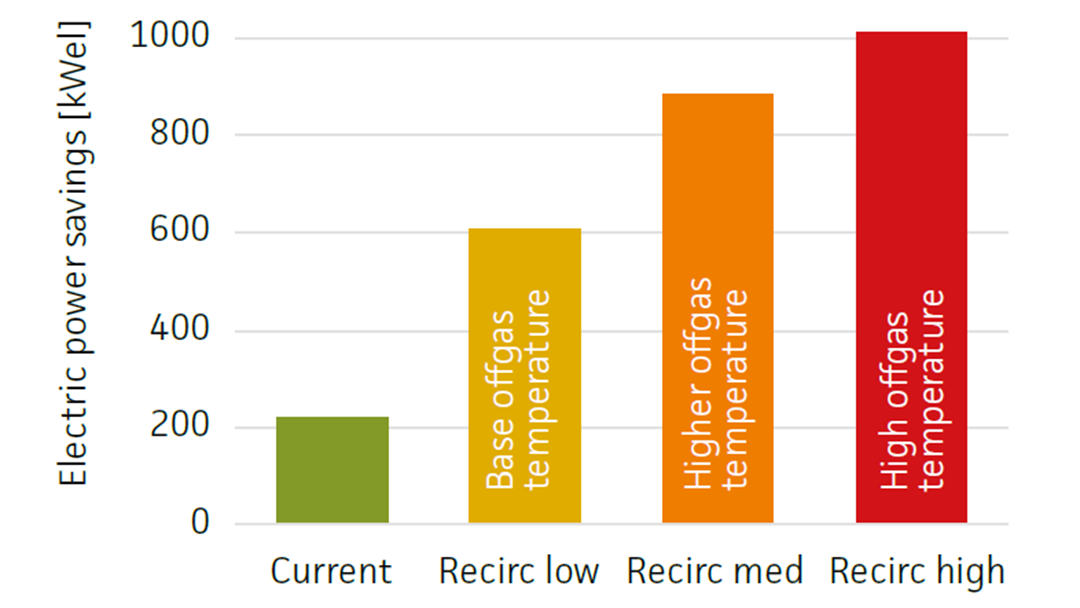

Aluminium is produced in large electrolysis cells where the core temperature is about 1000°C. The chemical reaction produces gas (mainly CO₂), initially at the same high temperature as well. However, to maintain the integrity of cell and surrounding equipment, the produced gas is continuously mixed with ambient air drawn into the cell and cooled down. Therefore, the offgas typically has a temperature of about 150°C – far colder than the core of the electrolysis cell. If the offgas temperature were higher, we could recover energy from it much more efficiently than today. One possible modification to the aluminium production process has a side effect that could make this possible. Research is currently being done on “off-gas recycling” – a measure to increase the CO₂ content of electrolysis off-gas, primarily to increase the technological and economic feasibility of CO₂ capture.

A side effect of this redesign is that the off-gas likely becomes significantly warmer, and heat recovery or gas cooling is a process requirement. When cooling it down, it is possible to recover heat and (for example) turn it into electricity – at a much better rate than with present-day off-gas temperatures. In our study, we have calculated how much more electricity a future aluminium plant could produce, compared to the current solutions.

The results show that the potential energy output of an organic Rankine cycle (ORC) could be more than four times larger in a plant with off-gas recycling compared to a present-day plant. This could lead to a large amount of saved energy in the electrolysis process. The work underlines a key finding that has been demonstrated many times in HighEFF: Energy efficiency has a much larger potential when the core processes are designed with such solutions in mind. This work was presented at the ORC2023 conference in Sevilla.

Thermochemical energy storage (TCES) involves storing heat by employing reversible reactions that release or absorb energy. Thermochemical storage provides high energy densities and the ability to store energy for extended periods. However, it necessitates complex systems and precise control mechanisms to effectively manage the chemical reactions.

HighEFF research in TCES started in 2022 with mapping the possibilities of TCES for waste heat recovery. The temperature range of TCES technologies is extensively wide, and the focus was directed on the most unexplored range, 100-300°C, as this fits the waste heat generated in several industry processes. NEIC project ITChES (Integration of ThermoChemical Energy Storage), was granted and started in December 2022, allowing more profound research on the potential of TCES. The knowledge building within HighEFF has shown TCES to be a relevant research topic for SINTEF Energy Research, and the work will be continued in further initiatives (e.g., KSP-initiative HiTES).

As a parallel activity, the possibilities of TCES using waste materials from the metal industry has been considered. Manganese-rich sludge from Eramet Norway was considered as a particularly interesting candidate. Unfortunately, experimental analysis revealed that the sludge is unsuitable for phase change or thermochemical energy storage due to the absence of phase transitions and water sorption properties. However, the material had suitable properties for sensible heat storage, and this possibility will be investigated further.

For decades, the refrigeration technology research groups at NTNU and SINTEF have been developing components, cycles and tools to promote attractive solutions using natural working fluids instead of synthetic fluids with undesirable environmental properties. This strongly contributed to the current situation where natural refrigerants such as CO₂ and hydrocarbons are commonly and competitively used in e.g. supermarket refrigeration and high-temperature heat pumps.

With growing interest in surplus heat and energy recovery, we again experience a situation where more environmentally friendly and secure long-term options for working fluids are needed; this time in efficient and competitive heat-to-power systems, such as Organic Rankine Cycles. With basis in developed knowledge from both refrigeration and heat-to-power, HighEFF students and researchers have searched for new potential applications of surplus heat-to-power conversion and applied themselves to broad technology development.

In a session keynote presentation at the 2022 Gustav Lorentzen Conference, the overall history of surplus heat-to-power research at SINTEF and NTNU was summarised, and our considerations related to benefits and drawbacks of relevant fluids discussed. The main point from comparing natural and synthetic fluids is that there is no difference in performance levels. Between CO₂ and hydrocarbons, a fully competitive natural alternative can be found with respect to performance.

High temperature heat pumps (HTHPs) are regarded as one of the main tools for increased energy efficiency in industrial processes. HTHPs enable industrial waste heat to be upgraded to elevated temperatures and reused into the process, using only a fraction of the energy compared to fossil fuel or direct electric heating.

One promising HTHP technology is the absorption-compression heat pump system (ACHP). The functionality of this technology has already been proven in the industrial sector using available standard components up to 120°C. A main advantage of this type of heat pump is that the ammonia-water fluid mixture allows for heat delivery at higher temperatures compared to traditional ammonia heat pumps, which are typically limited to 90°C. The heat delivery and uptake occur at gliding temperatures, which is beneficial when pairing against heat sinks and heat sources where sensible heat is transferred, e.g. heating of pressurised hot water.

Through the state-of-the-art ACHP test facility at HighEFFLab, specifications up to 40 bar system pressure, 200 kW capacity and 180°C operating temperature have been made possible. Construction of the rig was completed in 2022, and experimental activities led by HighEFF PhD student Khalid Hamid are set to begin during winter 2023.

The aim of the test facility is to achieve heat delivery up to 140°C and investigate key system characteristics such as COP, temperature lift and glides, as well as thermal capacity. System optimisation through investigation of different settings of the operational conditions, such as the ammonia-water composition, the circulation rate between the pump and the compressor, and pressure and temperature levels will also be performed.

SINTEF Energy Research with Hanne Kauko and Alexis Sevault co-authored a white paper on Industrial thermal energy storage together with researchers from Durham University (UK), TNO (the Netherlands), CIRCE (Spain) and AIT (Austria). The process was started in late 2021, and the white paper was officially launched during a digital event in December 2022, with 135 viewers from all over the world.

Industry accounts for one quarter of the total final energy consumption in the European Union. Within that quarter, over 80% is consumed by heating and cooling processes. The continued, wide-scale use of gas, oil, coal, and other fossil fuels for industrial thermal processes leads to estimated greenhouse gas emissions of 513 Mt CO₂ equivalent per year; which corresponds to 12% of total GHG emissions.

Thermal energy storage can assist in the decarbonisation of industrial heating and cooling and increase energy system flexibility and security. In the white paper, it is estimated that the full roll-out of industrial thermal energy storage could enable a potential 1,793 TWh of fossil fuel replacement by renewable energy and surplus heat.

While the general energy discussion is mostly focused on electrical energy storage such as batteries, the potential of thermal energy storage is largely overlooked. The aim of the white paper is to increase awareness of the potential of thermal energy storage as an enabler for decarbonisation and increased energy system flexibility among policy makers, industries, energy companies and the general public.

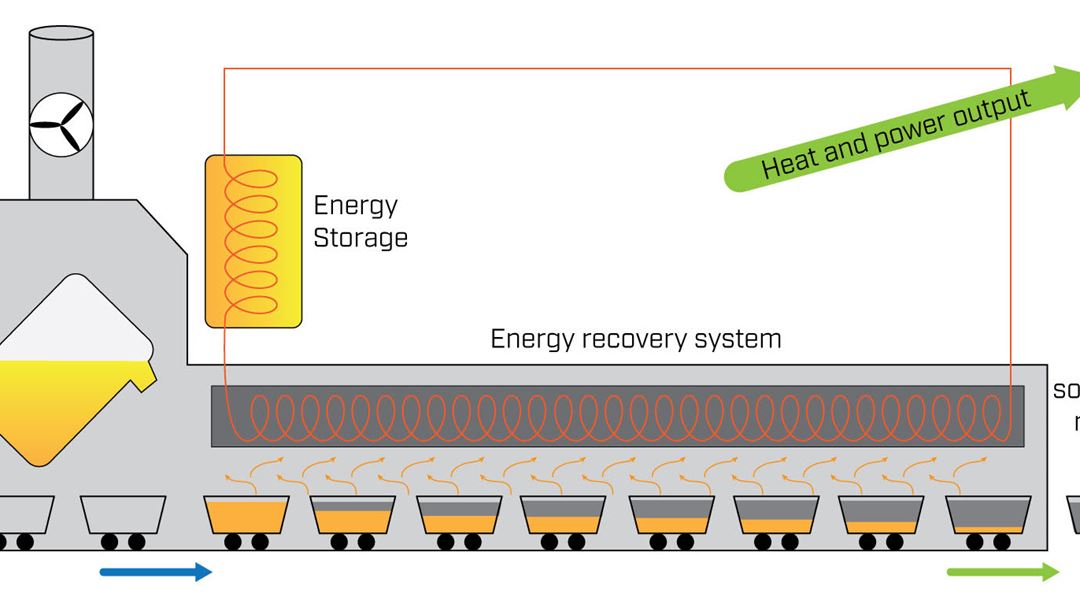

The significant amount of thermal energy contained in liquid metal makes the casting process at metal producing plants an interesting option for energy recovery. However, practical exploitation using current technology is complicated due to high temperatures, a highly dynamic process and strict product quality requirements. Previous HighEFF research proposed a system concept for capturing the heat released during casting. In 2021, practical approaches for utilising this heat through integration with a pre-existing steam cycle for off -gas energy recovery has been studied. A detailed, dynamic model of the Elkem Thamshavn energy recovery system has been used for this purpose, with results indicating an 11 % increase in electrical power production to be feasible with the additional recovered heat. The model was expanded with a thermal energy storage (TES) component to account for the batch- wise heat availability, which also benefitted the performance of the already dynamic conditions of the off-gas energy recovery system. Results will be published at the Gustav Lorentzen 2022 Conference.

When it comes to reaching the targets of the Paris agreement and decarbonising industry, high temperature heat pumps (HTHP) are considered the "hidden champions". Utilising the potential of industrial heat pumps is highly attractive since it allows the industry to operate with significantly reduced emission of climate gases as well as energy costs reductions.

Steam producing heat pumps are of particular interest for the industry since they can substitute existing fossil (steam) boilers Conventional supply systems are based on 8-15 barG process steam. The steam supply pressure from HTHP will for practical reasons be lower and is currently limited to around 5 barG, also due to efficiency reasons.

HTHP for the process industry will in most cases utilise industrial excess heat as heat source, however concepts based on ambient air and renewable energy sources are also being evaluated Several case studies were focusing on how to match specific on-site requirement to a technically and economically feasible HTHP solution.

SINTEF also organized the 3rd High Temperature Heat Pump Symposium. Different Spin-Off activities for HTHP were initiated and are presented to the HighEff consortium.

Orkla's confectionary factory in Trondheim needs large amounts of steam for various cooking processes. The factory currently has a propane-based steam production system, responsible for 30-40 % of the factory's annual CO₂ emissions In order to reduce the emissions, Orkla is interested in applying and electric boiler instead; however, this is currently not possible due to limited grid capacity in the area. To address this issue, the CETES-methodology developed previously in HighEFF was applied to see if introducing a thermal energy storage unit could allow satisfying the steam demand at a lower power demand. The study showed that by combining an electric boiler with a steam accumulator, the steam demand could be covered with a boiler capacity up to 41 % lower than the capacity of the current gas boiler. A steam accumulator would additionally allow shifting the steam production to periods with low demand in the power grid, thus reducing the pressure for grid capacity expansion. Depending on the electricity prices and emission taxes, as well as the allowed boiler capacity limit, the estimated payback period for the implementation was between 3 and 6 years.

The significant energy contained in liquid metal makes it an interesting source for energy recovery. This heat released during casting is difficult to utilise with current technology. Practical exploitation is further complicated by high temperatures, a highly dynamic process, and strict product quality requirements. The HighEFF research on novel concepts for metal casting energy recovery continued in 2020 with enhancing the dynamic system model to improve accuracy of the results and using the model to build an understanding of the complex relationships that will exist in future industrial implementations. We are learning how to design practically feasible concepts that can extract more than 80% of the available heat and output a steady production of electric power. This also includes integration of tailored thermal storage solutions to smooth the intermittent heat input from the casting process, identification of components that must endure very high temperatures, and a general evaluation of remaining technology gaps. This work has been the basis for excellent cooperation with the metal producing partners in HighEFF – on technical aspects and how to develop the idea towards a practical industrial demonstrator. The activity resulted in a conference publication at Rankine 2020, and securing a linked Novel Emerging Concept project called NECast.

The potential of high temperature heat pump for decarbonising industrial heat was evaluated from a Norwegian as well as a European perspective by this White Paper: Strengthening Industrial Heat Pump Innovation – Decarbonizing Industrial Heat.

The work is based on different case studies and heat pump developments of HighEFF and outlines that industrial processes are currently responsible for 20 % of total greenhouse gas emissions in Europe. In order to stay within the 1.5°C scenario of the Paris Climate Agreement, measures to reduce these greenhouse gas emissions from industry are urgently needed. HighEFF highlights the role heat pump technologies can fulfil in realising significant reductions in CO2 emissions arising from industrial process heating. Industrial heat pumps are a highly energy efficient, widely applicable technology to provide process heat. Driven by electric power, heat pumps are a key electrification technology which can replace a large share of fossil-fuelled industrial process heating.

A webinar with over 300 stakeholders was arranged in order to introduce the potential to a wider audience.

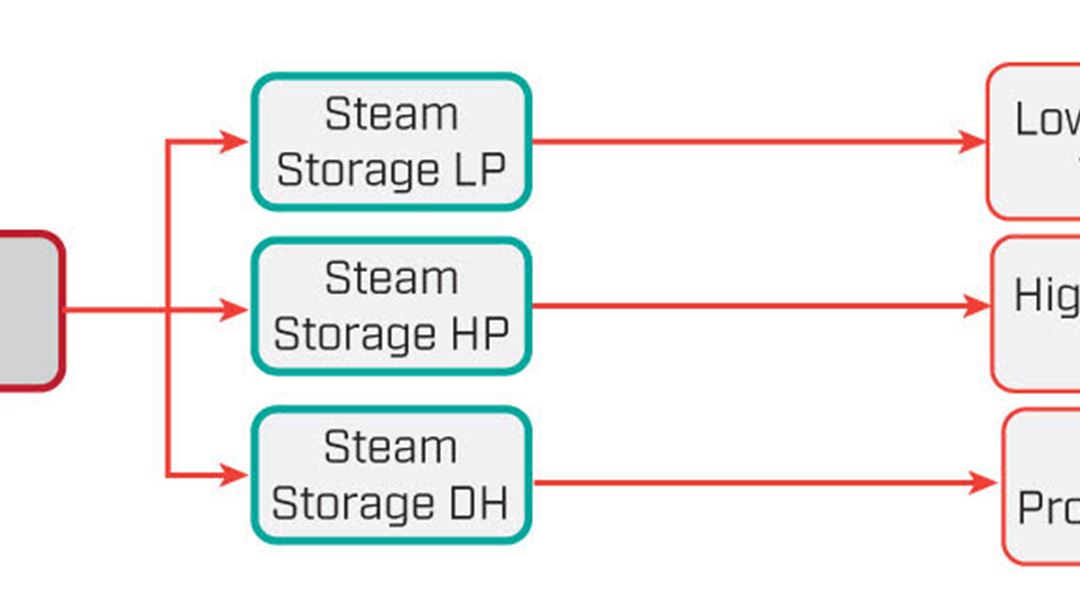

Elkem Thamshavn, located in Orkanger, is an important local employer and a global vendor for advanced silicon products and Microsilica™. The plant recovers energy from the off-gas of two silicon furnaces for electricity generation and heat export. Unlike a power plant, the system is not optimised for maximum electricity generation. However, the energy output could be increased through a short-term energy storage in the form of a steam accumulator. An optimisation model was built to address the trade-off between gains from power generation and storage size/costs. Three different cases for steam storage integration – see illustration – were identified within the Elkem steam system: low-pressure steam line, low-pressure turbine, and high-pressure turbine. The results indicate that LP steam line feed-in is the most economical solution for use of surplus steam, and a storage size of 10 m3 is recommended for implementation.

The energy recovery system at a silicon smelting plant has been analysed using a new dynamic model developed in HighEFF. Furnace off-gas energy recovery systems are subject to rapid changes in thermal load which is challenging with respect to both equipment safety and energy efficiency. The new model was applied to identify a new control strategy that can simultaneously boost electricity generation and improve thermal stability in the off-gas system. The model was developed and validated using data and measurements from the actual system.

Energy recovery concepts for practical energy recovery from metal casting have been evaluated. The thermal energy contained in the liquid metal in ferroalloy production makes it an interesting heat source for energy recovery. The starting temperature is typically in the range of 1500 °C which gives great potential for heat-to-power conversion. This heat is released during casting as the metal solidifies, but not utilized today. There are also some safety and environmental concerns related to common processes for Ferroalloy casting today. An initial new-concept evaluation that included a heat capture structure, thermal storage and power conversion was completed with promising results. A successful technical solution will not only improve the plant's energy efficiency, but also enable significant reductions in dust emissions and improved safety.

Upgrading industrial waste heat with high temperature heat pumps (HTHP) is a popular alternative for many industries. However, there are limits in both supply temperature and availability. For now, the industry standards can deliver supply temperatures of around 90 °C, while ongoing research projects and a few smaller heat pump companies can deliver supply temperatures up to 160 °C

Last year, two promising concepts for higher supply temperatures were analysed in depth. The investigated concepts were a 3-stage turbo compressors system using water as refrigerant, and a reversed Brayton cycle using CO2 as refrigerant. The systems were found technically and economically feasible solutions for process heat supply of up to 280 °C. These solutions are using large-scale equipment from oil and gas industries for applications in energy-intensive industries.

The suggested systems benefitted from the economy of scale and access to low electricity prices. The concepts outperformed a biogas-based solution, and they were competitive with biomass or natural gas systems with respect to economic performance. It was concluded that an electricity-based heat supply is possible for a wide range of industrial applications and accordingly represents an important contribution to fulfilling the objectives of lower climate impact of energy supply in industry. The results were published in the journal "Energy Conversion and Management."

In addition, an international conference on high temperature heat pumps in Copenhagen was organized by SINTEF and approximately 100 delegates from 13 different countries were present to discuss the most recent developments.

Shanghai Jiao Tong University experimentally investigated the performance of a 280 kW high temperature heat pump with water as refrigerant using a single stage screw compressor prototype.

Water is an excellent refrigerant for high temperature heat pumps because of the high critical temperature which theoretically enables condensation up to 373 °C. However, water requires a high evaporating temperature, around 70°C or more, because of the low steam density at low temperatures. The heat pump from Shanghai Jiao Tong University demonstrated a saturated temperature increase of 65 °C, and a maximum heat supply of 150 °C. The results were published in the prestigious journal "Energy".

Different thermal energy storage (TES) concepts suited for storing steam in industrial applications have been evaluated, with focus on four technologies: steam accumulator, latent heat storage, molten salt storage, and concrete storage. Industrial steam demand is enormous, and most of the demand worldwide is still covered by fossil fuels. Utilizing TES in combination with concentrated solar power or power-to-heat technologies (electric boiler or high-temperature heat pumps) opens up the possibility for steam production based on renewables, thus cutting emissions related to steam production. While a steam accumulator is currently the only off-the-shelf technology available for storing steam, it is only suitable for storage on very short time scales, and alternative technologies are required to facilitate the green shift in industrial steam production.

In addition to such short-term, high-temperature TES systems, a study on the technologies suited for seasonal storage of industrial waste heat has been carried out. Vast amounts of industrial waste heat is dumped into the fjords especially in the summer. Seasonal thermal storage may result in this heat being available for use in the winter. The outlet temperatures available from such storages are however moderate.

At the low-temperature end, PhD candidate Håkon Selvnes (NTNU) has continued his work on developing a novel cold TES technology based on phase change materials (PCM) for applications in the food industry. The construction of a prototype unit in the SINTEF/ NTNU laboratory at Gløshaugen was completed in mid-July, and tests have been carried out since August. This cold TES technology will potentially be implemented at a large poultry processing plant being under construction in Orkanger. The plant has a large and varying cooling demand and integrating cold TES in the refrigeration system may enable load shifting and a reduction in the required cooling system capacity by up to 20%, thus reducing both operational and investment costs.

A new methodology for design/off-design semi-steady state analysis of power production over variable heat source and -sink conditions was developed and demonstrated in a potential study on utilizing available surplus low-pressure steam at Mo Industripark. In addition to optimizing power output, the new methodology evaluated optimal distribution of heat exchanger sizes in the system using a novel "generic heat exchanger model" (GHX). HighEFF partner Alfa Laval contributed with performance data from their commercial heat exchangers to allow for a validation of the model; and the resulting comparison of heat transfer areas for the same design specifications matched very well.

Development of thermo-electric generation systems for industrial surplus heat conversion resulted in a preliminary concept design of a redundant 480 W (24 V) TEG system including electrical architecture. Work in 2019 will target source/sink heat exchangers and fouling aspects, as well as evaluating impact potential for a selected industrial application.

A heat pump for combined delivery of ice-water (0-4°C) and hot water (100-110 °C) was verified in a 20 kW demo unit in cooperation with HighEFFlab and HeatUp project. The compressor prototypes were delivered by HighEFF partner Dorin Innovations (through RA2). A concept for a closed loop heat pump system, based on turbo-compressors, was evaluated with focus on more compact de-superheating in order to reduce the system size. This activity will be followed up by experimental investigations in the next years. Additionally, the so-called reversed Brayton Cycle was investigated; which has promising results for heat delivery of up to 500°C.

The advantages of R744 for process chilling was moutlined and compared with state of the art freezing/chilling systems. Such systems show high potential mfor increased productivity due to the mincrease heat removal.

2018 activities were focused on two tasks: 1 evaluation of thermal energy storage (TES) potential for industry clusters to reduce the use of peak heating; and 2 mapping processes within the industries represented in HighEFF that are suitable for, and that could benefit from, the application of high-temperature TES.

The first task was carried out as a case study towards Mo Industry park, and the work will be continued during 2019. The most promising cases from task (2) will be investigated further with in 2019. PhD candidate Håkon Selvnes continued his work on a novel cold thermal energy storage (CTES) related to a mfood processing factory. A pilot CTES unit was delivered to the VATL laboratory at Gløshaugen by the local supplier Skala at the end of 2018, and the unit will be tested during 2019.