Researchers at SINTEF are developing small, mobile mirrors made of silicon – the same material that we use to make for example solar cells and microprocessors in our computers.

We recently used a micromirror to take accurate 3D images as part of a project for the European Space Agency (ESA), which needs a compact and very accurate 3D camera for use on Mars. We used the mirror to create a variety of different patterns using a laser beam. By decoding changes in the patterns, we captured 3D information to an accuracy of less than 0.1 mm, or slightly greater than the width of a human hair.

Micromirrors to Mars

Factors such as size, weight, speed, robustness and energy consumption are key to the use of micromirrors in space. Size and weight matter because it is very expensive to send anything to Mars. Speed is key because it is vital to take 3D images rapidly in order to guide sample collection in real time or observe objects in motion.

The mirrors can be moved with the aid of piezoelectric materials, which trigger movement when a voltage is applied. Since movement is integrated into the mirror elements, no external motors are required, making them more durable and able to withstand more stress. Moreover the mirrors have extremely low energy consumption and have a small footprint.

Low energy consumption makes our technology highly competitive. This is important because in space you can’t just plug your device into the mains. Such considerations are also important in other sectors. For example, autonomous drones fitted with sensors also have to operate for long periods before recharging their batteries.

Micromirrors with multiple applications

There is a link between the size of micromirrors and how fast and how much they can move. Increasing one of these parameters normally means a reduction in the other. At SINTEF we make mirrors across most of this parameter space, including fast and rigid mirrors with resonance frequencies of about 10 kHz, as well as those with large deflections and lower resonance frequencies of a couple of hundred hertz.

We are also looking into other micromirror applications. One example is their use in wireless optical communications, where they are used accurately to guide laser beams that enable high-speed optical communication without the need for a costly optical fibre infrastructure. Another is their use in laser-based wireless charging. Here, micromirrors are used to focus the beam onto the target device that requires charging, such as a wireless sensor. Charging commences when the beam establishes contact.

Micromirrors have many other exciting applications for future technologies. For example, they are important components of LiDAR systems. LiDAR is an optical remote measurement technique used to obtain rapid measurements of the location of, and distance to, physical objects such as autonomous vehicles. They may also be important components of low-energy projectors such as those used in augmented reality (AR) and virtual reality (VR) headsets.

Contact us if you have any questions about how you can use micromirrors in your business.

Combining MEMS mirrors with advanced micro- and nanostructured surfaces

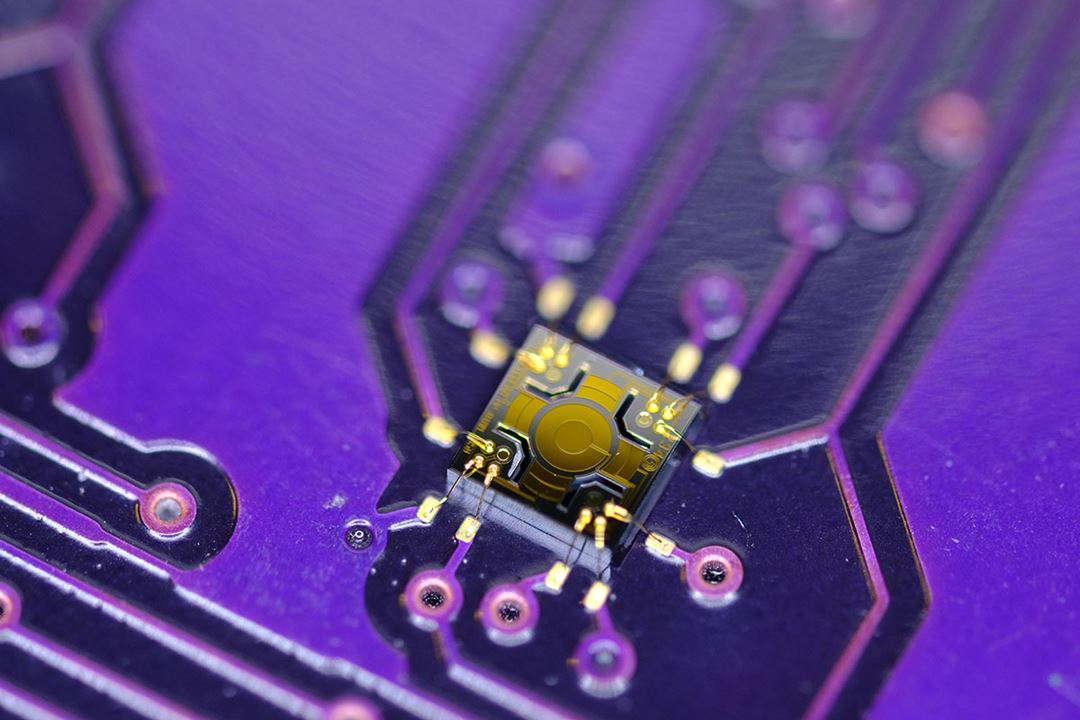

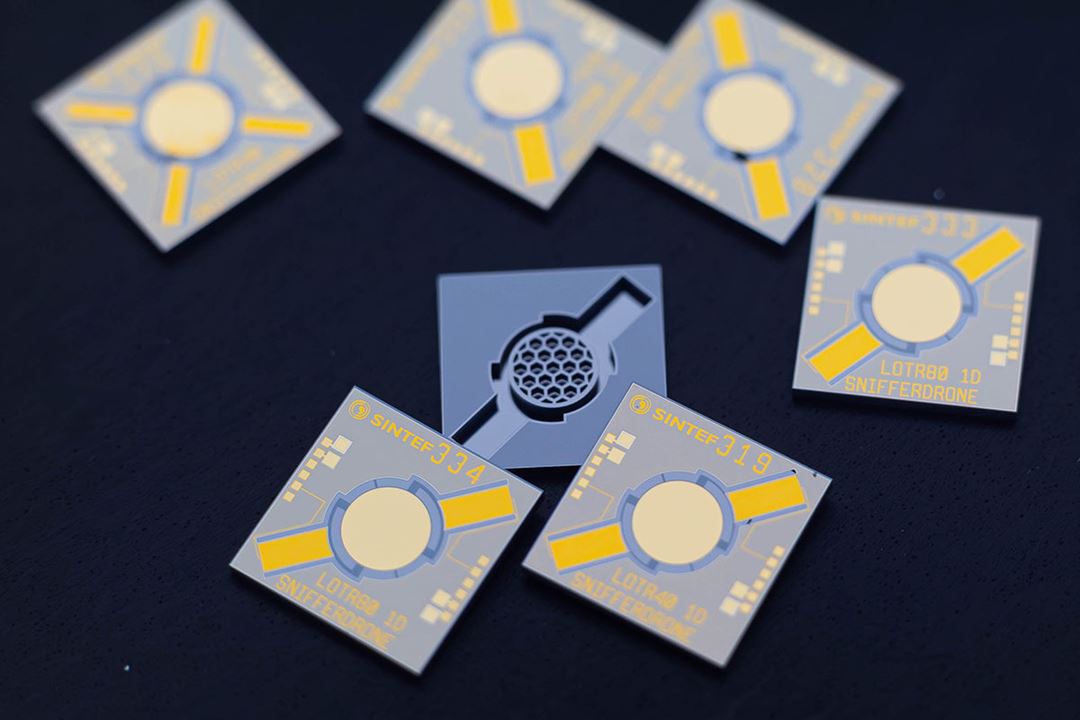

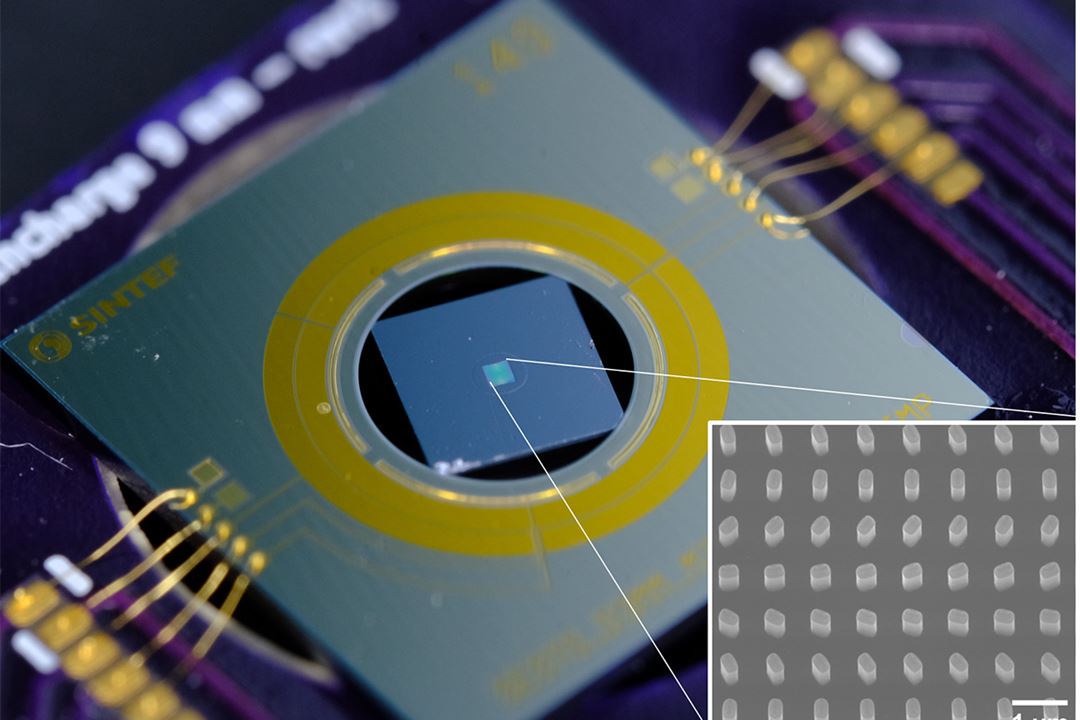

SINTEF is currently exploring the radical light shaping possibilities recently enabled by Optical MetaSurfaces (OMSs): Revolutionary ultrathin arrays of subwavelength resonant dielectric or plasmonic nanostructures that are intentionally designed to provide pointwise control of all the degrees of freedom of transmitted/reflected light - phase, polarization, amplitude, and dispersion (see insert in the figure below).

SINTEF integrates OMS with advanced piezoelectric thin-film PZT, thereby offering strong and rapid (>kHz) modulations of the optical properties in ultra-compact form factors (< 1cm3) while using ultra-low power (∼100 nW). This allows e.g. for the creation of varifocal tunable lenses (i.e. zoom-lenses) by displacing two metalenses relative to one another. One of our lenses has been written about in Laser Focus World. In collaboration with the University of Southern Denmark (SDU) we have used the platform to explore many more advanced paradigms for light control:

- Meng, Chao, et al. "Dynamic piezoelectric MEMS-based optical metasurfaces." Science Advances 7.26 (2021): eabg5639.

- Meng, Chao, et al. "Full-range birefringence control with piezoelectric MEMS-based metasurfaces." Nature communications 13.1 (2022): 2071.

- Ding, Fei, et al. "Electrically tunable topological phase transition in non-Hermitian optical MEMS metasurfaces." Science Advances 10.5 (2024): eadl4661.

- Thrane, Paul CV, et al. "MEMS tunable metasurfaces based on gap plasmon or Fabry–Pérot resonances." Nano letters 22.17 (2022): 6951-6957.

- Dirdal, Christopher A., et al. "MEMS-tunable dielectric metasurface lens using thin-film PZT for large displacements at low voltages." Optics Letters 47.5 (2022): 1049-1052.

- Dullo, Firehun, et al. "Metasurface lens that is converging or diverging depending on transmission direction enables ultra-compact MEMS tunable reflective lens." arXiv preprint arXiv:2402.02755 (2024).