A First-Principles Approach

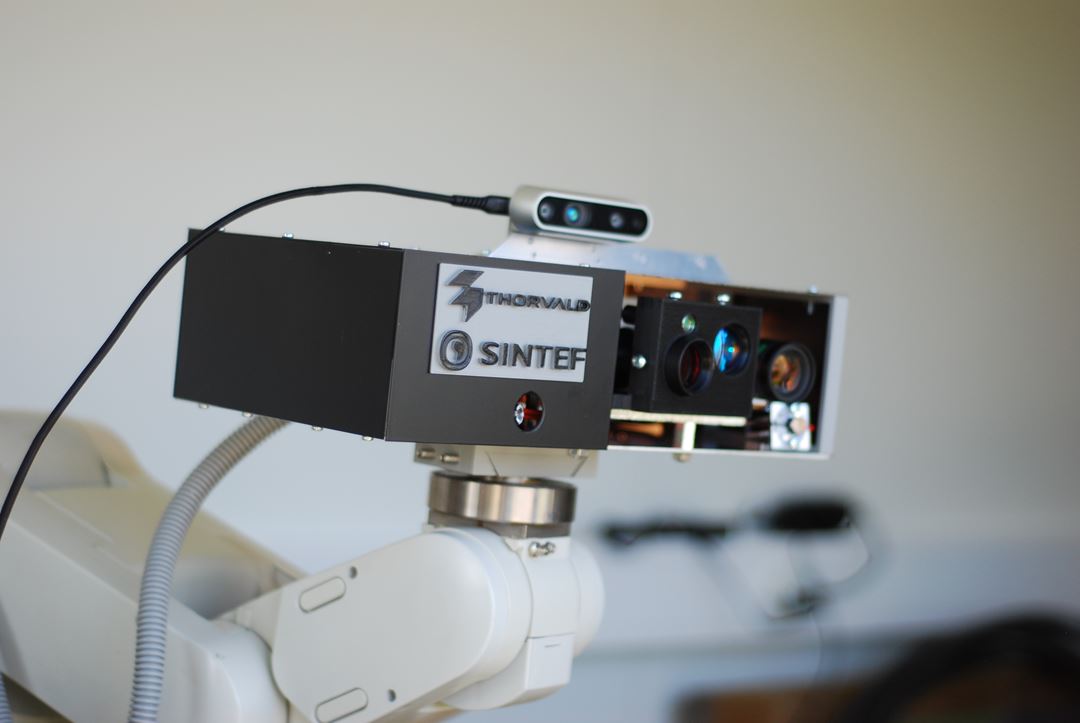

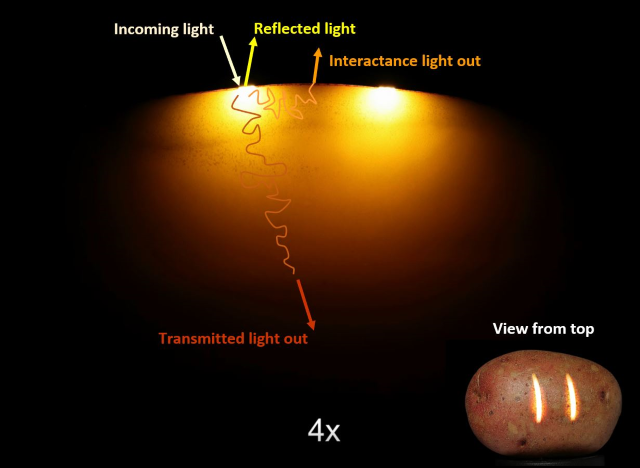

We base our design process with the fundamentals of physics and light, whiich allows us to select the right measurement geometry, wavelength range, and data modeling method for each application. For example, we have shown that interactance- based systems, using a measurement technique where light travels inside the sample before being detected, can predict strawberry sugar content, even in outdoor conditions with sharp sunlight. This contrasts with common reflection-based systems that only sample the surface and often fail in variable environments and between seasons.

Solving What Others Struggle With

Our solutions routinely succeed in demanding cases:

- Potatoes: Inline prediction of dry matter content in whole potatoes for high-speed French fry lines, with geometry-tuned NIR systems that measure beneath the surface of each potato.

- Tomatoes and strawberries: Non-contact sugar measurement while the fruit is in motion, enabled by smart geometries and robust modeling.

- Protein hydrolysates: Real-time monitoring of enzymatic processes using dry film FTIR spectroscopy using a new prototype that was customised for use in industry. This was the first step towards process optimization and quality control directly in industrial settings

In each case, SINTEF’s approach proved reliable under real-world constraints, where signal quality, ambient noise, and biological variation must be overcome.

Sensor Development That Bridges the Valley of Death

At SINTEF, our food sensor innovation doesn’t end with a prototype. We have also a record of building toward commercialization:

- We co-develop our food sensors with close industrial end-user involvement

- We can implement Minimum Viable Product (MVP) strategies, for fully testing advanced prototypes in industrial settings over time

- We have a strategy of patent protection

- We aim for cross-sector testing for commercial scalability

- We use our expertise to strengthen the competitive edge of existing commercial products

Our work is supported by close collaborations, e.g. with the food researchers at Nofima and NMBU, farmers and industrial food producers, ensuring our work stays grounded in market and process realities. This is the way to make sensors that truly work in demanding conditions — from clipfish to crab to strawberry.

We are part of a Centre for Research and Innovation called Digifoods, with Nofima and NMBU, with long-term strategy for digitalisation in the food industry, focussing on a combination of novel optical sensors, robotics, and advanced data analytics. The centre has many partners covering different stages of the food and technology value chains. Our consortium is paving the way for an exciting research and innovation journey for the food industry.

Side view of a potato being illumination with two defined light strips (insert on bottom right is the top view). The random path of a photon is illustrated as it bounces around the inside of the food.