Multiphase Flow Laboratory

SINTEF Multiphase Flow Laboratory is one of the world’s largest multiphase test facilities and a research Infrastructure of national importance.

SINTEF Process Innovation Park (PIP) is a leading independent test and development facility at near industrial scale. For more than 40 years, we have been a key partner for industry, offering a unique combination of deep scientific expertise and advanced infrastructure that enables research based piloting and scale up.

With access to state of the art pilot plants, custom built rigs and precise instrumentation, SINTEF PIP is specifically designed to support technology development towards higher levels of technological maturity (TRL 6 to 7).

We develop and test a wide range of technologies including process equipment, sensor technology, chemicals, process and design simulators, material integrity, drones and robotics.

At PIP, you will find research based knowledge and hands on experience that contribute to optimising sustainable processes under realistic industry relevant conditions. Whether you are working on recycling, new materials or low emission processes, we are ready to support you throughout the entire development journey.

Today, our facilities include much more than low emission oil and gas production. They also offer test areas and laboratories for CO₂ capture, hydrogen technology, energy storage and bioprocesses. We are ready to support your innovation from idea to demonstration.

SINTEF Multiphase Flow Laboratory is one of the world’s largest multiphase test facilities and a research Infrastructure of national importance.

The CO2 laboratory at Tiller is a highly equipped test facility for development of post-combustion CO2 capture technologies, as well as a research lab for flue gas pre-treatment analysis and emission research.

The catalysis pilot lab is a laboratory designed to conduct experimental campaigns that simulate industrial conditions for a range of catalytic processes.

The Smart-H hydrogen macromechanical lab is designed for research aimed at increasing the understanding of the hydrogen influence on materials mechanical properties.

Laboratoriet er unikt i sitt slag, da det muliggjør testing av materialer og komponenter med kombinert høyt trykk, høy temperatur og høy spenning, med grenser på 1000 bar, 200 °C og 100 kV.

SINTEF performs experimental research on thermochemical biomass conversion using laboratory units in the range from bench- to semi-pilot scale.

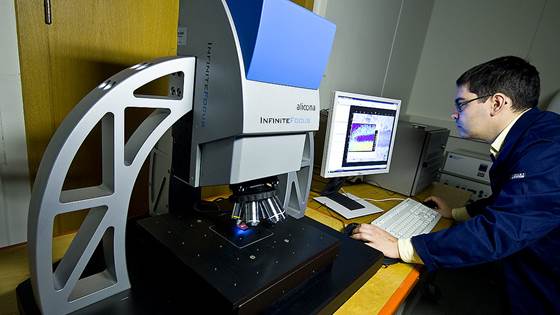

Tribology is the multidisciplinary science on wear, friction and lubrication of interacting surfaces in relative motion. Research in tribology is often highly dependent on the final application. The mission of the Tribology Lab at SINTEF/NTNU is to...

AURORA will further develop and demonstrate advanced CO2 capture technologies to the point of commercial deployment.

The main objective of the HyLINE II project is to enable safe pipeline transport of hydrogen gas by building a knowledge base covering the hydrogen effect on pipeline steel welds and its influence on the overall integrity of the pipeline.

The PYROCO2 project will demonstrate the scalability and economic viability of carbon capture and utilization (CCU) to make climate-positive acetone out of industrial CO2 and renewable electricity derived hydrogen.

Visiting address:

Tillerbruvegen 200, 7092 Tiller, Norway

Postal address:

SINTEF AS, P.O. Box 4760 Torgarden, NO-7465 Trondheim, Norway