Research group of Process Chemistry and Functional Materials

Combinatorial chemistry

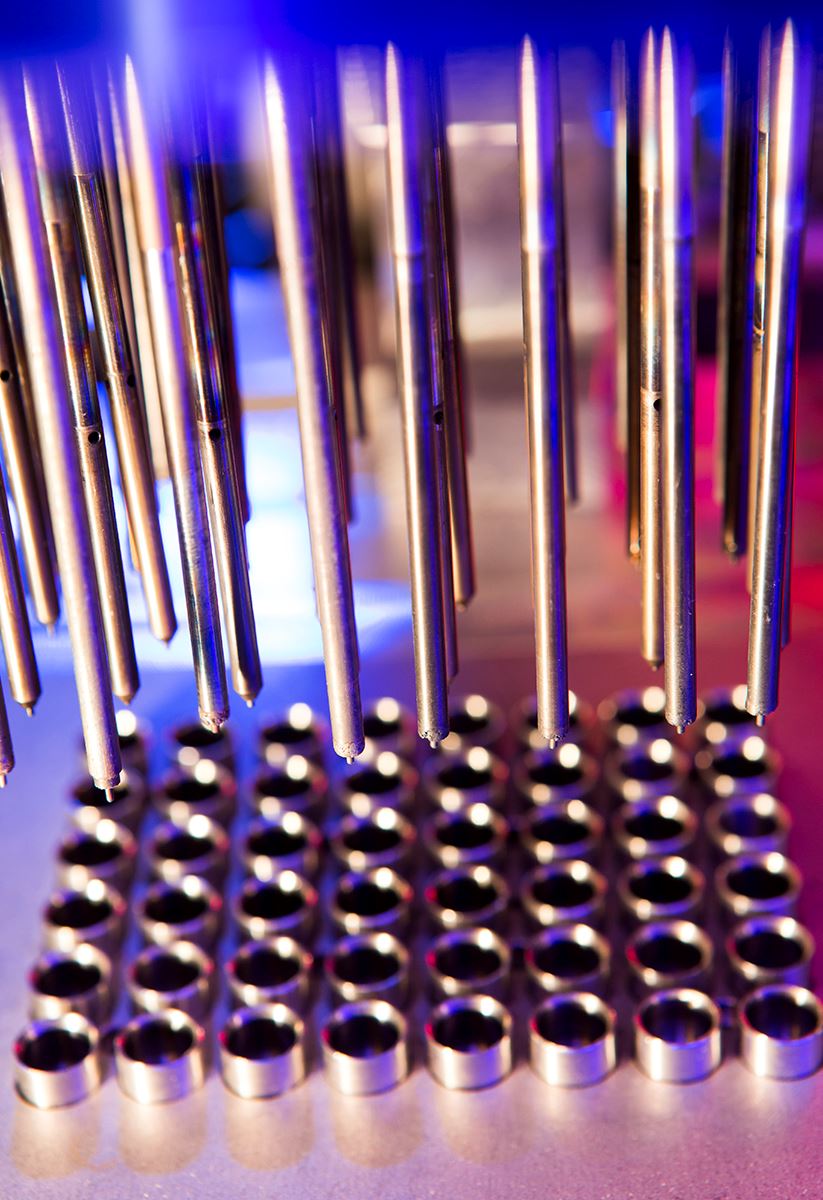

Our "COMBI" facilities have proven to be essential in understanding and optimizing various chemical processes, enabling users to develop and understand the intricate relationships between food, catalyst/sorbent, process conditions, and the resulting yield and selectivity of a given chemical process.

Fully automated means fully automated. The COMBI plants give the user full control over feeding, process conditions and analyses. Analysis and method development are implemented directly in the process control software, which greatly simplifies data processing, storage and processing.

Imagine what you could do with the pilot plant's quality data generated from a microscale plant running 10 – 100+ reactors in parallel, all equipped with independent control of food, process conditions and analyses.

The group also runs its own laboratory for combinatorial synthesis and functionalization of materials, as well as testing of materials for use in catalysis and separation and optimization of process conditions.

Commissioned research is a central part of what we do. In addition to delivering valuable services to the industry, contract research allows us to build expertise, operate and further develop our systems. We currently have several long-term research projects and are constantly looking for new opportunities.