SFI Manufacturing builds on existing national capabilities and aims to strengthen the Norwegian manufacturing companies' ability to innovate. The centre seeks to mirror the inherent cross-disciplinary innovation systems in the industry and combine research on multi-material product solutions, flexible automated manufacturing and organizational processes.

The innovation process itself is a core research topic and SFI Manufacturing strives to be a basis for unleashing innovation potentials and research challenges embedded in the crossdisciplinary interfaces, and to develop new research methods. The research activities in SFI Manufacturing are organised in three research areas:

1 Multi-material products and processes

To develop the ability to optimize material choice, multi materials geometry and processes simultaneously. The work is lead by Einar Hinrichsen in SINTEF Industry.

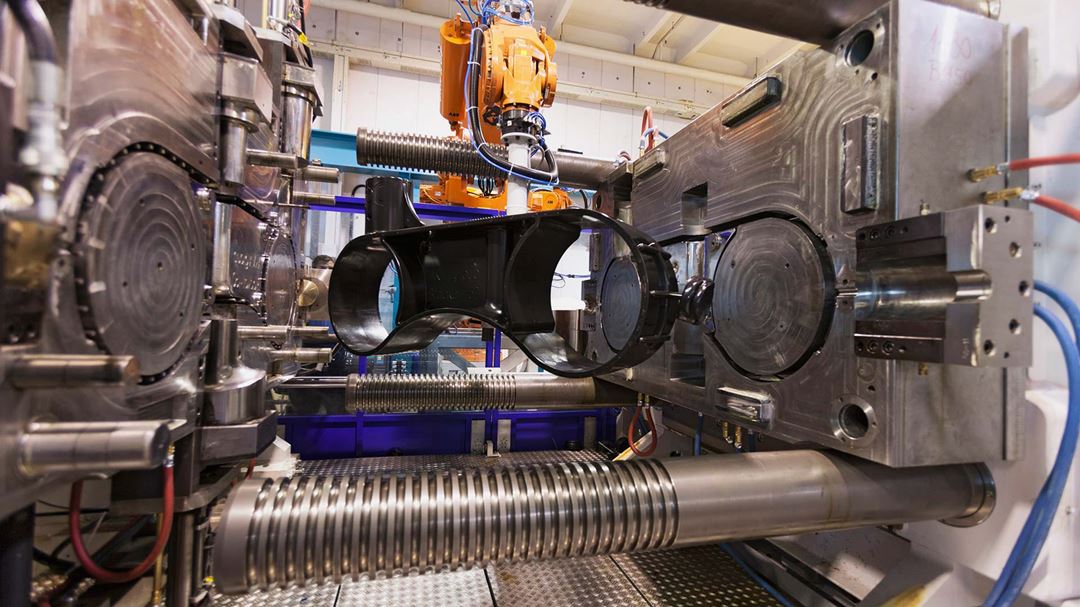

2 Robust and flexible automation

To further develop and link novel technologies and methodologies within automation to support innovation processes and advanced work systems in the manufacturing industries. The work is lead by Gabor Sziebig in SINTEF Manufacturing.

3 Innovative and sustainable organizations

To develop advanced work systems that are enabled to utilize new technology and flexible and automated processes to manufacture sustainable multi-material product solutions. The work is lead by Heidi Carin Dreyer at NTNU.

Consortium

- Benteler Automotive

- Brødrene Aa

- Ekornes ASA

- GKN Aerospace Norway AS

- Hexagon Raufoss

- Hydro

- Kongsberg Automotive

- Nammo AS

- Neumann Aluminium

- Plasto AS

- Rolls-Royce

- Sandvik Teeness AS

- HyBond AS

- Mjøs Metallvarefabrikk AS

- NTNU (3 faculties involved)

- SINTEF (3 institutes involved)

- SINTEF Manufacturing AS (host institution)