Additive manufacturing (AM)

AM is the use of additive processes in "regular" industrial manufacturing, not just for prototypes or models. There are some applications for which AM offers special advantages and possibilities compared to traditional production methods such as subtractive manufacturing (e.g. machining) or forming methods (e.g. casting).

Here are some examples:

- Stiff and strong lightweight components, e.g. printed with internal lattice structures or designed using topology optimization

- Components with taylored geometry in order to fit into tight spaces

- Spare parts printed locally on demand

- Moulds for moulding/casting with plastics and metals, e.g. with special features such as conformal cooling channels

- Components for dental, medicine and health applications

Additive manufacturing also opens for process-induced microstructures in the material. Furthermore, the process can combine materials, and make gradients in material composition or material properties in a product.

Several different AM processes

Several different AM processes and materials are now commercially available, and new or improved processes and materials are introduced each year. Note that a given process has certain possibilities and limitations. Hence, a company wishing to manufacture a part by AM should first identify the best process(es) for their part.

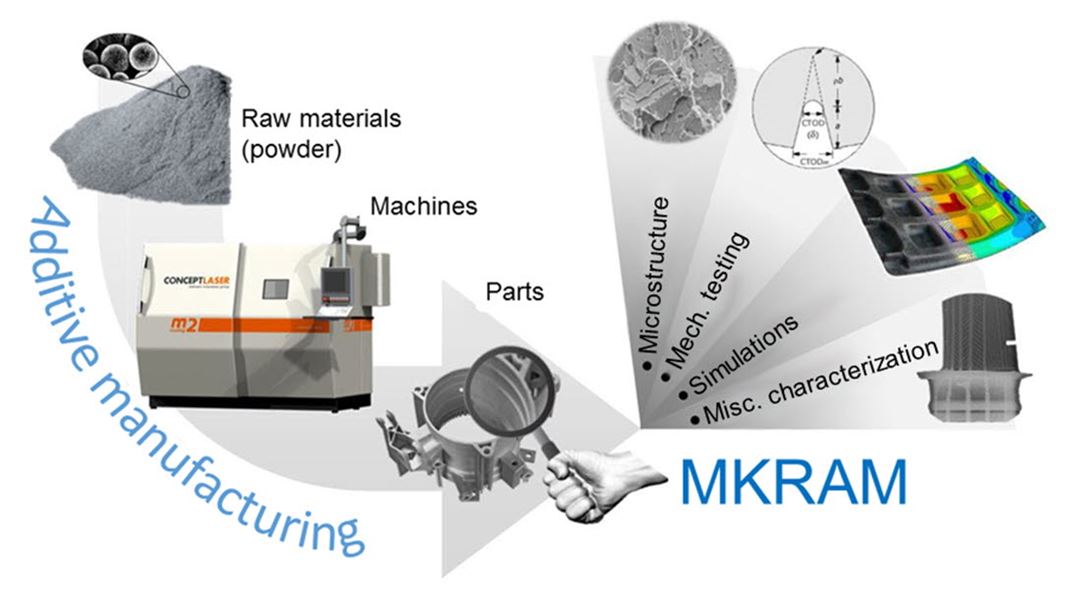

The MKRAM project

The MKRAM project has focused on so-called powder bed fusion processes, in which powder particles (with diameter typically < 0.1 mm) are fused together layerwise into a 3D part. The energy for this fusion is typically delivered by a laser beam, but some machines for metals use an electron beam. Such powder bed fusion processes are important industrially, and they are known by names such as selective laser sintering, selective laser melting etc (many of these terms are trade names).

When it comes to materials, the MKRAM project focused on certain metal alloys (mould steels and Ni-superalloys) and polymer materials (polyamides with and without reinforcement).

The aim of the MKRAM has been, in short, to understand the effective material properties of parts made by the AM processes mentioned above. This include mapping and understanding the repeatability, i.e. the variation in properties from part to part, from machine to machine, and with different materials and powders.

There are several challenges related to AM of structural parts, i.e. mechanically loaded parts. Regarding the performance of such parts, there are challenges related to the effective material properties (including factors such as anisotropy, often induced by the layerwise manufacturing, and process-induced residual stresses) and the variation in properties from component to component (which has several sources). In some cases the effective material properties achieved by AM can be quite different from those that are known from traditional manufacturing methods (with the same material).

The MKRAM project partners

R&D partners: SINTEF Industry, SINTEF Manufacturing, NTNU (Gjøvik and Trondheim campuses). These R&D partners have experience in additive manufacturing of metals and plastics from earlier projects. NTNU has three industrial powder bed fusion AM machines. The project has funded two PhD students.

Industrial partners: GKN Aerospace Norway, Kongsberg Automotive (Raufoss), Nammo Raufoss, OM BE Plast, Sandvik Teeness.

The MKRAM project has been financed by the industrial partners listed above and The Research Council of Norway (via the BIA programme).