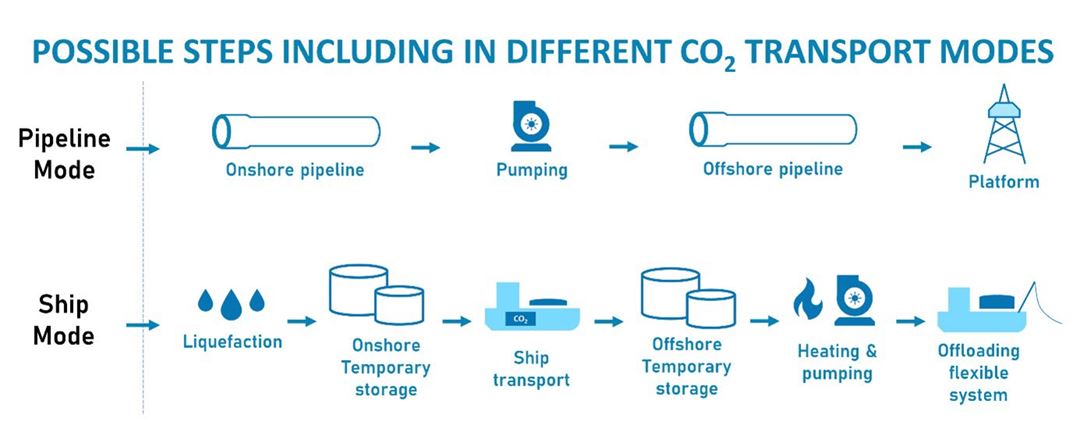

Sustainable and efficient deployment of carbon capture and storage (CCS) requires suitable and reliable solutions at all levels of the value chain. Demonstrations of capture and storage technologies developed in the last decades have already realised a TRL able to support a quick CCS deployment, but knowledge gaps still exist regarding which polymer materials may be safely and effectively used in the CO2 transport infrastructure (e.g., elastomeric seals, gaskets, pipe liners etc as leakage seals and protective barriers). Transport of supercritical CO2 by pipeline or transport of cryo-compressed CO2 by ship create very different, but both highly demanding environments. These environments have different effects on polymeric materials and can lead to transient and permanent changes in the materials (such as stiffening, cracking, seal leakage and premature part failure), resulting in re-emission of the CO2 during transport.

The CO2 EPOC project aims to close these knowledge gaps by investigating the compatibility between polymeric materials and CO2 streams. A multilevel approach will be used, from experimental characterization of how representative polymers react to CO2 (including contaminants), to fundamental modelling to predict this behavior in other application scenarios. This knowledge will be disseminated to close these knowledge gaps and enable more informed polymeric material selection within the CO2 transport chain.