Today, the industry's factory acceptance stress tests for high voltage electrical equipment used in converter-fed networks are still largely based on conventional, slow 50 Hz sinusoidal voltages because there is a lack of reliable international test standards for insulation coordination under power electronic stresses.

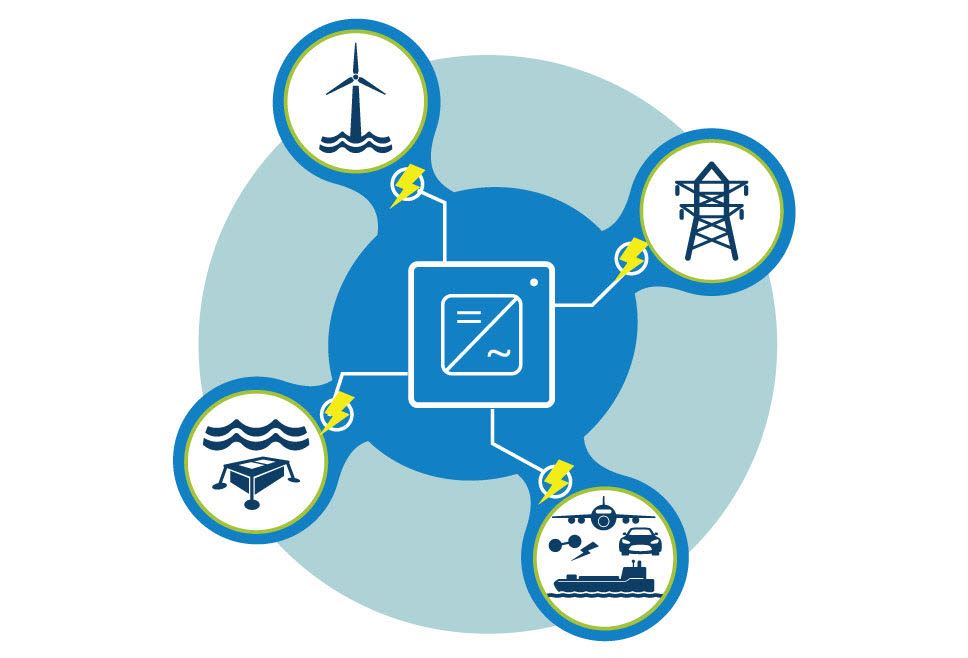

FastTrans aims to address these issues by developing knowledge, equipment, models and techniques for testing and insulation coordination of high voltage electric power apparatus in networks stressed with fast rise time repetitive voltage pulses from power electronics.

The project focuses on three specific R&D challenges that are particularly important for the development of generic test standards:

- Partial discharge occurrence and detection

- Pulse propagation in networks into components

- Ageing diagnostics

The project accommodates the full diversity of high voltage insulation systems, which range from the µm-sized and sharp-edged internal insulation in an integrated gate bipolar transistor (IGBT), to more uniform geometries in polymer cables, epoxy-insulated machines, and oil/cellulose-insulated transformers.

The research documentation emanating from the project is expected to be sufficiently comprehensive to approach international organisations such as IEC and CIGRE for the development of generic and reliable test standards for high voltage equipment under the influence of fast transient stresses from power electronics.

Project partners:

- NTNU

- University of Bologna

- Infineon

- Statnett SF

- Equinor Energy AS

- ABB AS

- Statkraft Energi AS

- Elvia

- Aker BP AS

- Total E&P NORGE AS

This is a KPN-project (Knowledge-building Project for Industry) financed by the Research Council of Norway.