BIGCCS - International CCS Research Centre

CO2 Storage

Contact person

CO2 monitoring technologies

Overall objective:

The main objective of the monitoring task is to improve CO2 storage safety by accurately localizing the CO2 plume, quantifying CO2 volumes, and enabling early detection of potential leakage.

Contribution to one or more of the overall goals/objectives of BIGCCS

CO2 storage is the final link in the whole CCS chain, as defined in the overall BigCCS centre objective of enabling sustainable power generation from fossil fuels based on cost-effective CO2 capture, and safe transport and underground storage of CO2. Monitoring to avoid, and remediation measures in cases of leakage are the indispensable knowledge to ensure permanent removal of GHG from the atmosphere.

Achievements thus far:

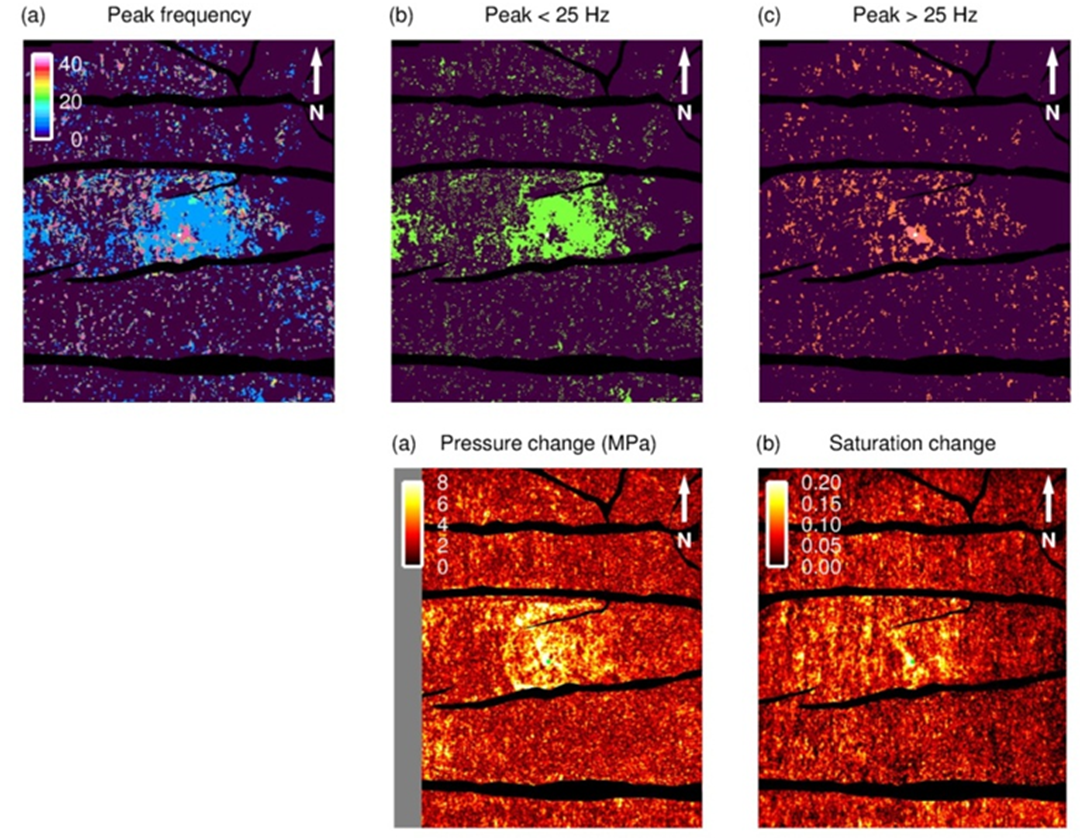

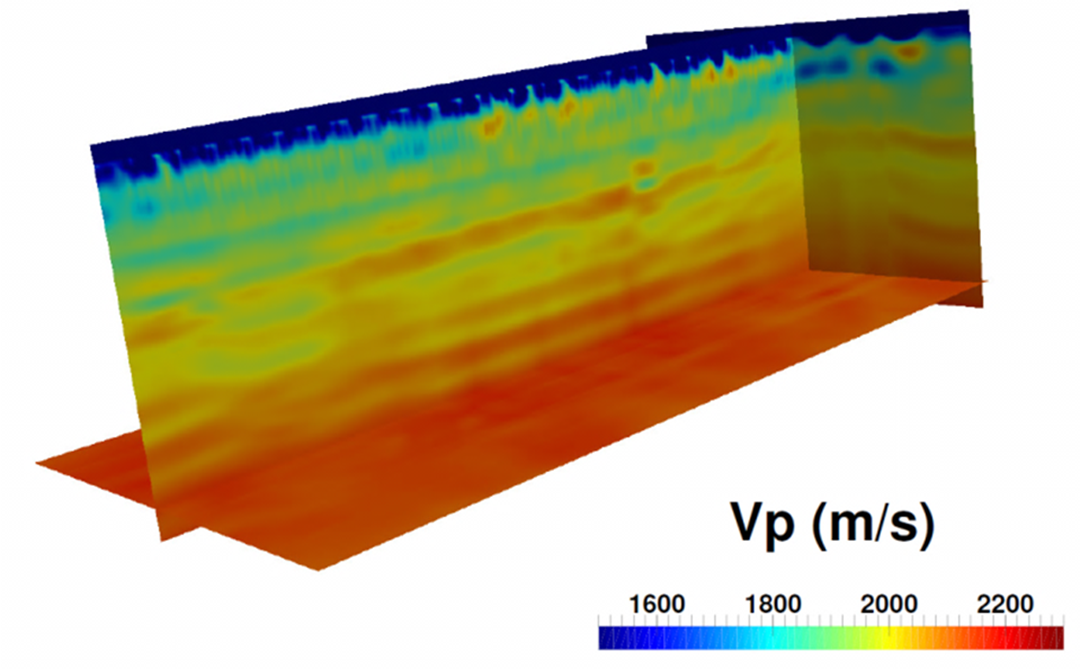

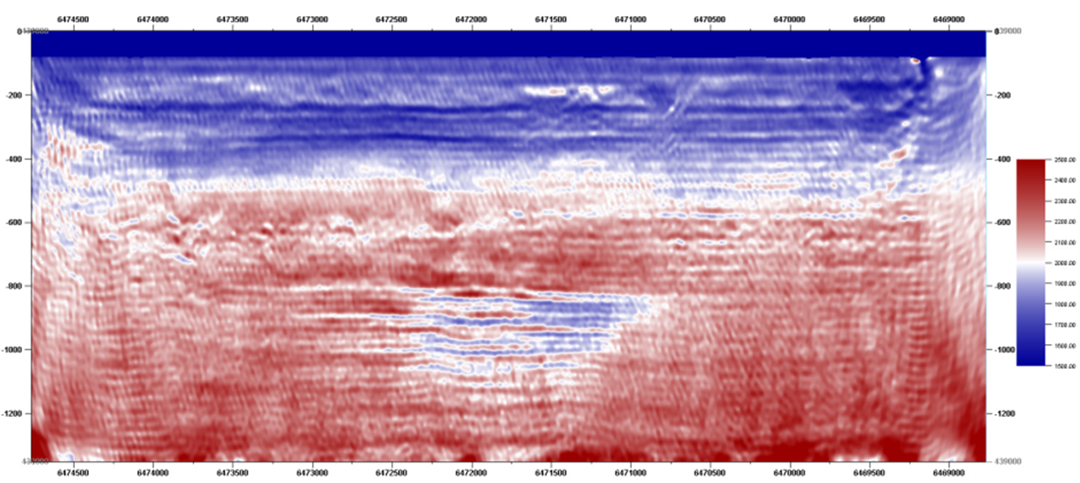

- Several geophysical methods succeed in visualizing the CO2 plume in the Sleipner reservoir, despite its structure in thin layers. We now can zoom in on the topmost plume layer and see it appear from the repeat seismic surveys on site; this is good news for our ability to detect leakages early on. Moreover, good progress is made on separating useful signal from background noise, indispensable for detection of very thin CO2 layers, while the seismic velocity changes can be separated in terms of pressure increase and saturation changes.

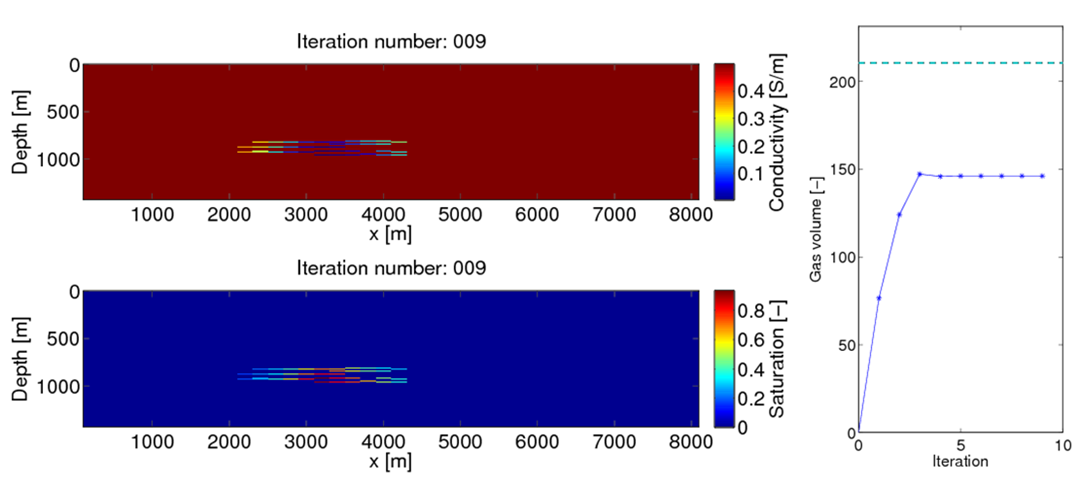

- Detection of CO2 in the underground using electro-magnetic sources has been demonstrated. This will be a promising addition to the traditional seismic methods.

- Laboratory ultra-sonic velocity measurements on rock plugs subjected to stress changes simulating injection into a reservoir have given vital information for interpreting integrity compromising stress developments, opening the door for sonic well-to-well monitoring. In addition, the data will help calibrate the velocity interpretation of seismic monitoring schemes.

Major achievements in 2014

- Performed Snøhvit pressure/saturation discrimination study (collaboration BGS/NTNU, see Fig. 1).

- Developed a novel methodology for quantitative leakage detection

- Developed and tested framework for 2D/3D elastic time-lapse FWI on real data (see Fig. 2).

- Initiated new KPN project on quantification/reduction of uncertainties in monitoring. First version of work bench for uncertainty estimation and reduction in high-resolution monitoring methods to be delivered during November.

- Completed study of 2D high-resolution plume imaging at Sleipner (see Fig. 3).

- First 3D high-resolution image of Sleipner plume (using 2008 data set).

- Completed synthetic study of CO2 volume estimation using constrained CSEM inversion and noisy data (see Fig. 4).

- 12 publications!

Related publications

- Utilizing spectral decomposition to determine the distribution of injected CO2 at the Snøhvit Field

James C. White, Gareth A. Williams, Sissel Grude and R. Andrew Chadwick | Geophysical Prospecting | 2015 - A numerical study of 3D elastic time-lapse full-waveform inversion using multicomponent seismic data

Espen Birger Raknes and Børge Arntsen | Geophysics | 2015 - Three-dimensional elastic full waveform inversion using seismic data from the Sleipner area

Espen Birger Raknes, Børge Arntsen and Wiktor Weibull | Geophysical Journal International | 2015 - Permeability variation with porosity, pore space geometry, and cement type: A case history from the Snøhvit field, the Barents Sea

Sissel Grude, Jack Dvorkin and Martin Landrø | Geophysics | 2015 - Synthetic seismic time-lapse analysis of saturation and pressure response to CO2 injection into layered reservoir

Rasmus Rasmussen and Peter Frykman | International Journal of Greenhouse Gas Control | 2015 - Seismic imaging of the carbon dioxide gas cloud at Sleipner using 3D elastic time-lapse full waveform inversion

Espen Birger Raknes, Wiktor Weibull and Børge Arntsen | International Journal of Greenhouse Gas Control | 2015 - Pressure effects caused by CO2 injection in the Tubåen Fm., the Snøhvit field

Sissel Grude, Martin Landrø and Jack Dvorkin | International Journal of Greenhouse Gas Control | 2014 - CO2 saturation and thickness predictions in the Tubåen Fm., Snøhvit field, from analytical solution and time-lapse seismic data

Sissel Grude, Martin Landrø, James C. White and Ole Torsæter | International Journal of Greenhouse Gas Control | 2014 - Elastic velocity analysis and time-lapse full-waveform inversion

Espen Birger Raknes, Wiktor Weibull and Børge Arntsen | The Leading Edge | 2014 - A synthetic Sleipner study of CO2 quantification using controlled source electromagnetics and full waveform inversion

Peder Eliasson, Anouar Romdhane, Michael Jordan, Etor Querendez | Energy Procedia | 2014 - CO2 characterization at the Sleipner field with full waveform inversion – Application to synthetic and real data

Anouar Romdhane and Etor Querendez | Energy Procedia | 2014 - CO2 Thin-layer Detection at the Sleipner Field with Full Waveform Inversion: Application to Synthetic and Real Data

Anouar Romdhane, Etor Querendez and Celine Ravaut | Energy Procedia | 2014 - Time-lapse full waveform inversion of limited-offset seismic data using a local migration regularization

Espen Birger Raknes and Børge Arntsen | Geophysics | 2014

CO2 reservoir containment

Overall objective:

To provide improved understanding of the fundamental effects of CO2 injection on geomechanical and sealing properties of a storage reservoir and the cap rock.

Contribution to one or more of the overall goals/objectives of BIGCCS

The storage part of BIGCCS is focused on developing CO2 storage-related issues to a level that enables long-term and safe storage. One of the stated goals in this part of BIGCCS is to improve the current knowledge on the interactions of CO2 with the storage volumes. This also includes interactions with the necessary sealing formations for the storage volumes.

Achievements thus far

This task is a KPN associated with BIGCCS, and has funding running from January 2012 to December 2014.

The activity on near-well integrity has in the first part of the funding period focused on the possible development of near-well radial fractures as a result of the cooling effect of the injection CO2 well-stream. First modeling results indicate that fractures compromising the integrity of a sealing shale layer could develop if the well-stream is more than 50 °C colder than the formation. This situation could occur if cold CO2 from a transport ship is injected without pre-heating into a deep reservoir. The research results thus highlights the importance of proper temperature control and modeling of the effect the cooling can have on the formation.

The modeling work is followed by laboratory tests, where discs of shale rock are subjected to strong temperature variation while being constrained by a metal frame in a fixed position in such a way as to create a dilation stress strong enough to create fractures. Some development of laboratory techniques has been necessary for this work.

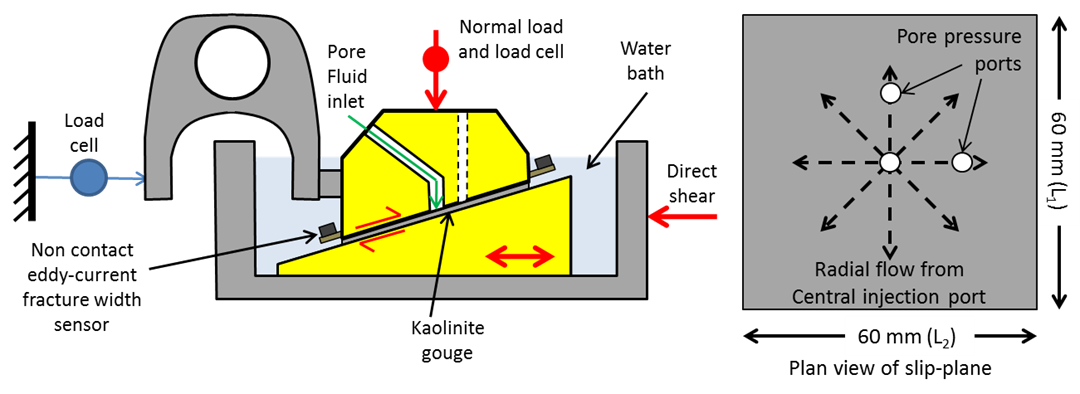

The focus of the activity on flow properties of faults has in the first part of the Task 3.4 funding period been to prepare a custom-made laboratory rig. The apparatus allows investigation of flow properties of a fault gouge material under very small fault shear rates and under varying normal loads.

The activity on flow properties of partially sealing rock has in the first part of the funding period concentrated on testing experimental methods for measurement of the capillary entrance pressure of low permeable rock. The method chosen is to expose one end of a water-saturated core plug to CO2 of gradually increasing pressure, while keeping the other end at a fixed pressure. The interfacial tension between CO2 and water acts together with the contact angle between CO2, water and mineral surfaces to block the CO2 from entering the pores of the rock sample until a given pressure difference (the capillary entrance pressure) is exceeded. The changed water chemistry resulting from the presence of CO2 may for some minerals lead to a change in the contact angle and thereby to a reduced entry pressure. This is the topic of the next phase of work in this activity.

Related publications

- Laboratory testing of shale rock specimens to assess thermal fracturing risk in caprock surrounding injection wells

Cerasi, P., Stroisz, A.M., Walle, L.E., and Lavrov, A. ARMA 14-7077. This paper was prepared for presentation at the 48th US Rock Mechanics / Geomechanics Symposium held in Minneapolis, MN, USA, 1-4 June 2014. | | 2014 - CO2 capillary entry pressure into flow barrier and caprock

Raheleh Farokhpoor, Idar Akervol, Ole Torsæter, Bård J. A. Bjørkvik. SCA2013-A054. This paper was prepared for presentation at the International Symposium of the Society of Core Analysts held in Napa Valley, California,, USA, 16-19 September, 2013. | International Symposium of the Society of Core Analysts, Napa Valley, California, 16-19 September 2013 | 2013 - Numerical modeling of tensile thermal stresses in rock around a cased well caused by injection of a cold fluid.

Cerasi, P., Stroisz, A.M., Walle, L.E., and Lavrov, A. ARMA 13-306, This paper was prepared for presentation at the 47th US Rock Mechanics / Geomechanics Symposium held in San Francisco, CA, USA, 23-26 June 2013. | | 2013

Well integrity

Overall objective:

The main objective of the task is to improve CO2 storage safety and cost-efficiency through developing a more detailed understanding of how, why, where and when leaks develop in/along wells penetrating CO2 storage reservoirs. A special focus will be on CO2 injection wells and abandoned exploration wells.

Well integrity and its importance for CCS

Wells have in numerous scientific studies been denoted the «weak link» of safe and cost-efficient CO2 storage. Whether they are active or abandoned, these wells are all man-made intrusions into the storage reservoir – and their sealing abilities depend on engineering materials like steel and cement. Maintaining well integrity means to prevent leakage in/along wells. This is important throughout the well’s life cycle, from drilling to plugging and abandonment.

Read more about the importance of Well Integrity for safe CCS in the BIGCCS blog.

Contribution to the overall objectives of BIGCCS

The research results generated in the present task can potentially lead to innovations important for various players in the CCS market, especially operators and service companies. It can lead to development of tailored materials, fluids and strategies for safer and more cost-efficient CO2 well construction, operation, remediation and abandonment. Other potential developments are new ways to secure the integrity of an already plugged exploration well, or methods to transform existing petroleum wells into CO2 injection wells.

Research activities

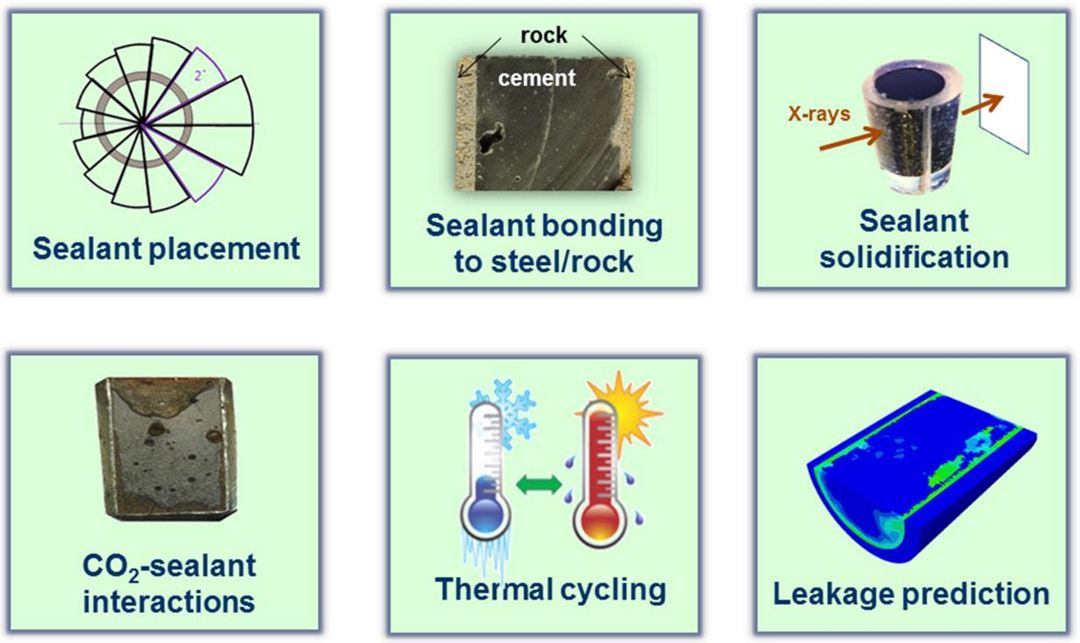

Task 3.5 aims to investigate well integrity issues occuring during the whole life-cycle of a well, from the early well construction phase to the time when the well will be permanently plugged and abandoned (P&A’ed). A schematic overview of the research topics we are focusing on is given in the figure below, and the word «sealant» is here a more generic replacement for cement (which is the most common annular sealant and plugging material).

In summary, Task 3.5 aims to investigate:

- Sealant placement: How can a given sealant best be placed in wells to ensure an even annular seal and to avoid mud channels or pockets?

- Sealant bonding: How can we optimize the bonding of a given sealant to its surroundings in a well (rock/steel)?

- Sealant solidification: How can we ensure that leakage paths do not form during sealant solidifcation (e.g. as a result of shrinkage or the development of weak zones near solid walls)?

- CO2 -sealant interactions: How are various selant materials (both annular sealants and plugging materials) affected by exposure to CO2? Can we optimize sealants (structurally or chemically) for use in CO2 wells? Could research-based advice be given on which materials to construct and plug wells with in a large-scale CCS scenario?

- Thermal cycling: How is CO2 well integrity affected by the temperature variations that must be expected in the well during CO2 injection? Do leakage paths appear (e.g. as a result of sealant de-bonding or cracking), and if they do – how can we best predict, prevent and remediate them? Can we determine «safe temperature windows» for a given well type?

- Leakage prediction: Can we estimate leakage rates and consequences of the well integrity failure modes that are observed in the activities above? Can these results be upscaled from laboratory to well scale?

Task 3.5 achievements thus far:

Sealant placement simulations

A numerical code has been developed to study sealant placement in wells. This has been used to investigate how cement flows and displaces mud in a well. The effect of throughgoing break-outs and casing eccentricity on cementing quality was studied. All this was presented at the 8th Trondheim CCS conference (TCCS-8) in June 2015.

Sealant bonding

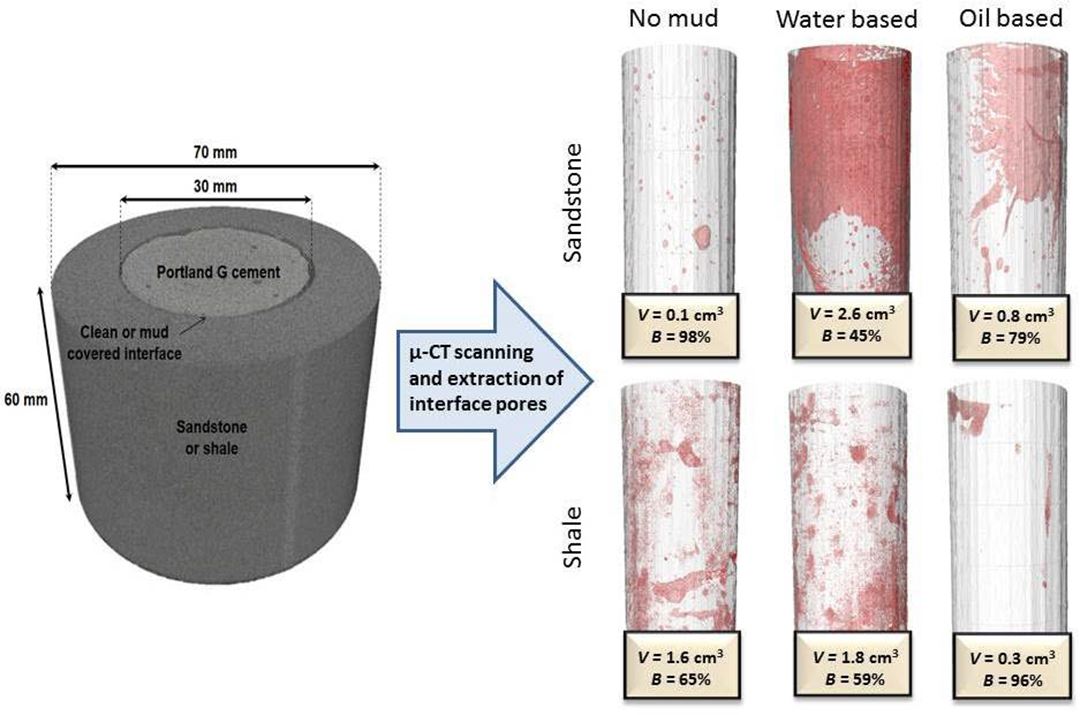

Using micro-CT, we have visualized and quantified how tightly well cement bonds to various rock formations. The impact of different drilling muds has also been investigated. The work indicates that fluid choices made already during drilling of a well will affect its long-term well integrity. New information has also been provided on the size, three dimensional (3D) geometry and density of interface leakage paths (or «microannuli»). This is important for remediating them efficiently. The experimental methodology is illustrated in the figure below, and ongoing experiments focus on flowing CO2 through the samples.

Sealant solidifcation

The interface transition zone (ITZ) is a weak zone forming in cement when it solidifies near solid walls. The defect has long been known to exist in construction engineering. Despite its importance for leakage along active and abandoned wells, this topic has not been studied in detail with respect to well cementing. Using detailed characterization methods, like scanning electron microscopy, in combination with physics-based calculations, we have given an overview of the importance of ITZ for CO2 wells in the journal Construction and Building Materials. We have also been granted funding for a project entited «Closing the gaps in CO2 well plugging», which will study sealant solidifcation in greater detail. This will focus not only on cement, but also on other materials that are candidates of replacing cement as a well plugging material. Some of the first work performed in this new researcher project was presented at TCCS-8. The plans in the new researcher project are also outlined in this poster prepared for CLIMIT Summit 2015.

CO2-sealant interactions

American researchers have recently observed that CO2 exposure can lead to self-healing of cracks in/along cement. This is because the volume of cement increases upon carbonation, and it indicates that CO2 is an efficient well remediation fluid. We have performed some experiments building on this important observation, and this work was presented at TCCS-8.

We are also using high-resolution micro-CT combined with the Avizo software to determine how CO2 reacts with cement and rock when drilling mud is present on/in these materials. This is important in order to optimize mud choices for prolonging CO2 well integrity. A poster was prepared on this topic and presented at the TCCS-8 conference in Trondheim in June 2015.

Thermal cycling

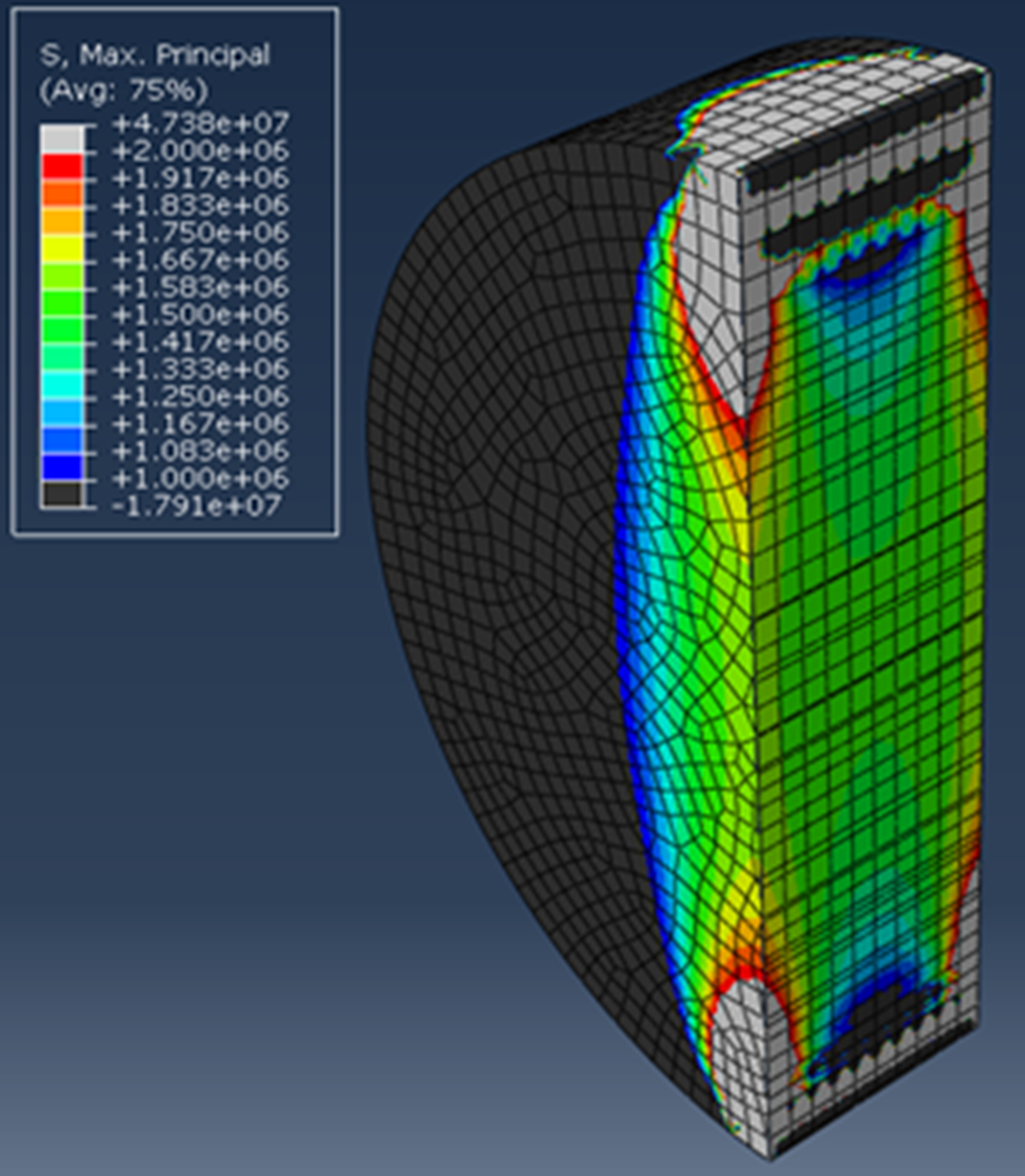

This work involves using medical CT data from real downscaled well sections (rock, cement and casing) in ABAQUS. We have found that defects in the annular cement sheath dictate the robustness of a well. The more defects – the lower the resistance towards thermal cycling. This work was presented during the ARMA conference in June 2015, and published in a paper after the conference. A numerical model has also been developed for heat transfer in wells, and this was presented at the SPE Bergen One Day Seminar on April 22nd 2015, with a publication being released directly after the conference. This work explores how different annular sealant materials affect the temperature transfer in the well during CO2 injection. More information on the work performed on thermal cycling can be found in this poster prepared for CLIMIT Summit 2015.

Leakage prediction

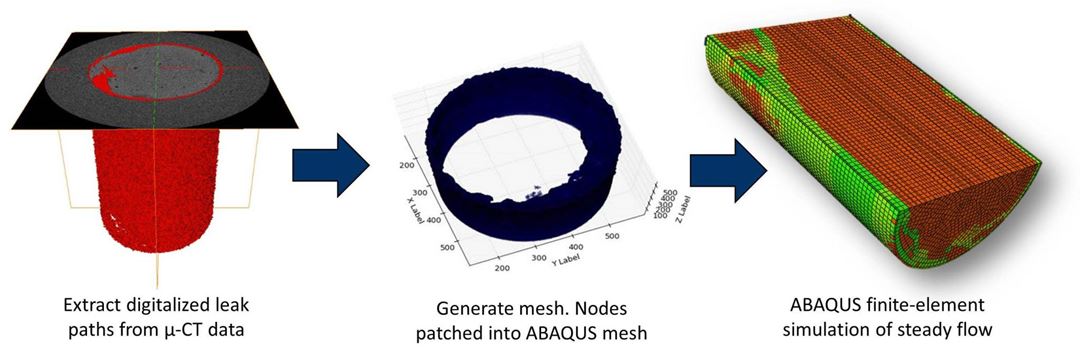

We have established a computational roadmap for how to calculate flow through digitalized micro-CT data using the ABAQUS software. The methodology is illustrated in the figure below. The work has revealed that leakage rates through microannuli can be reduced by reducing the leak path area normal to flow and/or the permeability of the leak path. Simulations have been made to calculate the flow through microannuli along the shale-cement interface, and these calculations have been experimentally verified in the GEUS laboratory. A peer-reviewed publication has been submitted on this work in January 2015. Some of our work on CO2 leakage along interface microannuli will also be presented at the ARMA conference in June 2015, and published in a paper after the conference.

Other information

The work performed in this task is a continuation of work performed in BIGCCS SP3 in 2013 (in task 3.3), and it involves experimental cooperation between SINTEF Petroleum Research and GEUS. A KPN project entitled «Ensuring well integrity during CO2 injection» is administrated as a part of the task, and SINTEF Energy Research and Lawrence Livermore National Laboratories are contributing to this work. In January 2015 we will also start up a new researcher project entitled «Closing the gaps in CO2 well plugging». As for the KPN, this project is also administrated as a part of Task 3.5. The partners contributing to the researcher project (in addition to SINTEF Petroleum) are: SINTEF Materials and Chemistry, NTNU, Universite du Maine and Curistec.

- CO2 reactivity with mud-affected cement and rock

- Effect of eccentric annulus, washouts and breakouts on well cementing quality

- X-ray Tomography Studies of Cements for Safe Plugging of CO2 Wells

- Structure and debonding at cement–steel and cement–rock interfaces: Effect of geometry and materials

- Plugging and abandonment (P&A) research at SINTEF

- Numerical study of tensile thermal stresses in a casing-cement-rock system with heterogeneities

- Implications of Stress State Uncertainty on Caprock and Well Integrity (FEW0191).

- Impact of voids on mechanical stability of well cement

- How do you pump cold CO2 into the warm continental shelf without damaging the well?

- From PhD student to researcher – opportunities and challenges

- Filter Cake Behavior during Leakage at the Cement-Rock Interface in Wellbores

- Effect of Thermal Cycling on Well-bore Integrity during CO2 Injection

- Cements for Safe Plugging of CO2 Wells Studied by X-ray Tomography

- Cement self-healing as a result of CO2 leakage

- Study of Thermal Variations in Wells During CO2 Injection

- Ensuring well integrity during CO2 injection

- Closing the gaps in CO2 well plugging

- Enabling long-term storage of CO2 at large scale

- Avoiding leakage from wells – the key to safe CO2 storage

- Potential Leakage Paths along Cement-formation Interfaces in Wellbores; Implications for CO2 storage

- Near-well integrity and thermal effects: a computational road from laboratory to field scale

- Leakage through microannuli in wells

- Integritet i CO2 brønner

- Leak Path Development in CO2 Wells

- Leakage of CO2 along cement-formation interfaces in wellbores

Enabling large scale CO2 storage and EOR

Overall objective:

The main objective of Task 3.6 is to conduct research on case studies on CO2 storage sites with injection rates in the Mt/year range.

Detailed objectives include:

- Direct and align the research in SP3 towards this objective, including collaboration with other projects on the implementation of large-scale CO2 storage in the North Sea.

- Increase the understanding of possible issues with formation pressure increase as a result of CO2 injection on a large scale and suggest ways to manage pressure in such a way that both storage safety and storage capacity is maximised.

- Develop and provide calculation models for aquifer storage and CO2 EOR for the value chain work in BIGCCS SP4.

Contribution to one or more of the overall goals/objectives of BIGCCS

- Common to the research topics is the focus on developing knowledge important for enabling large scale CO2 storage and EOR.

- In order to make a measurable contribution to climate change mitigation, CCS must be implemented on a large scale, with annual injection rates for storage sites in the Mt CO2/year range. It is an ambition for SP3 of BIGCCS to make a valuable contribution to research that enables storage on this scale.

Goals for 2015

- Investigate possibilities for establishing an industry funded main project based on the work in the Gassnova-funded phase of the Sentrallager project.

- Improve estimates for maximum safe injection pressure in an aquifer based on analysis of existing borehole breakout data.

- Develop methodology for optimal use of large aquifers for multiple independent injection operations

- Establish the framework for improvement of modules for CO2 storage and CO2 EOR in the BIGCCS CO2 chain model.

Related publications

Qualification and management of storage resources (2009-2013)

Overall objective:

The main objective was to develop procedures and tools to integrate data for qualification of prospective CO2 storage sites including development of modeling tools for pressure prediction during CO2 injection.

Contribution to one or more of the overall goals/objectives of BIGCCS

Following industry advice, BGS intend to attempt to better understand and quantify the stress field within the Southern North Sea (SNS). Making use of the extensive well data available to BGS for this region, we plan to compare the break-out data from the Bunter Sandstone down through the Zechstein salt and into the Carboniferous bedrock. It is postulated that the salt serves to decouple the overburden from the bedrock and the regional stress field may not apply in the Bunter Sandstone.

Major achievements

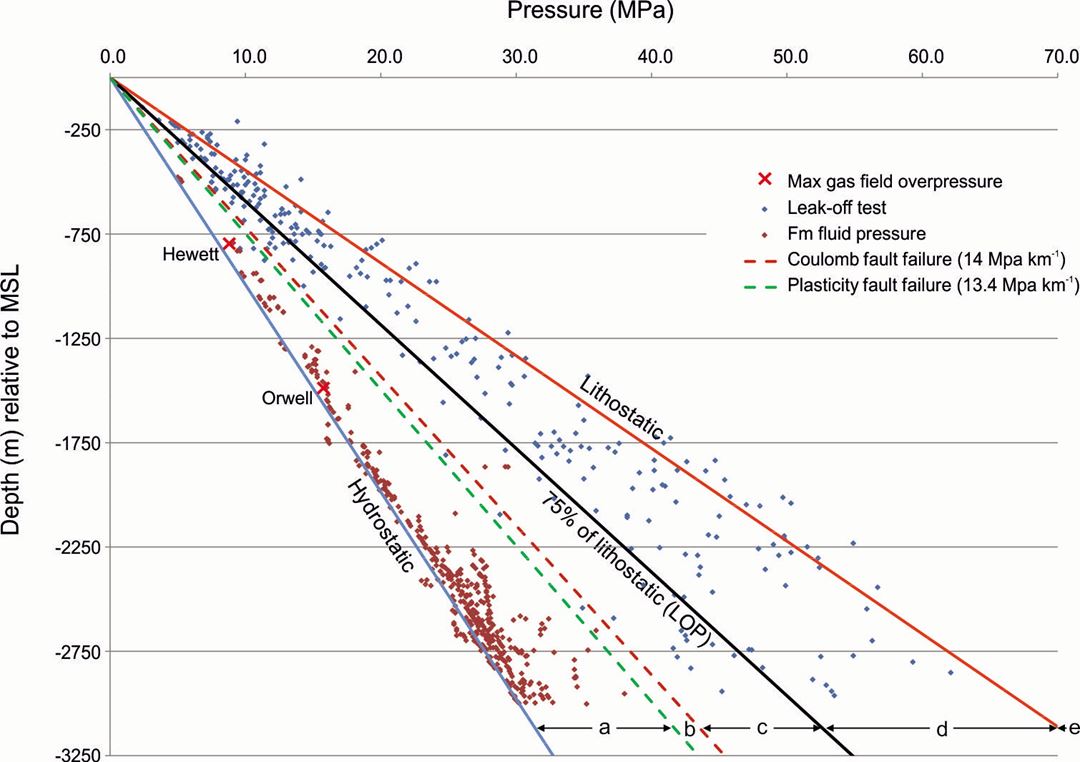

One of the activities – Large scale CO2 modeling with BGS in lead – contributed to the objectives of BIGCCS by research related to large scale modeling of pressure development in potential CO2 storage sites by analyzing field data from the Southern North Sea, showing the relationship between the hydrostatic, lithostatic, leak off pressures (LOP) and modeled fault failure (reactivation) gradients. It is possible that LOP values falling between the various pressure gradients are influenced by the following factors: Tests not being fully taken to leak-off (a), reactivation of optimally oriented faults (b), reactivation of non-optimally oriented faults (c), failure of intact rock (d), or local variations of the lithostatic pressure gradient and spurious LOP measurements (e).

All the flow modelling studies have followed the same injection strategy:

- 12 Injection wells and 2 Mt year per well injection rate

- 50 year injection period

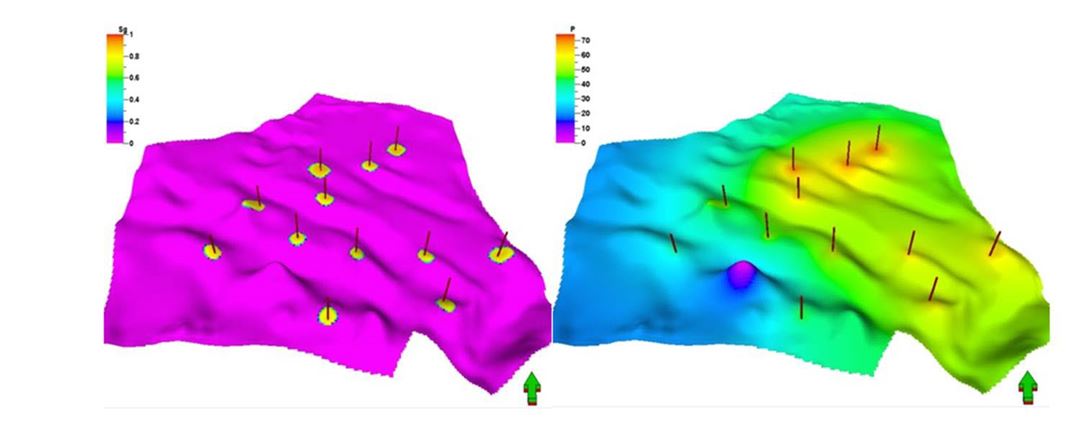

The Bunter is assumed to have 100mD reservoir permeability in the following examples. Initially, the injection is limited by the fracture pressure at the wells and 1196 Mt of CO2 can be injected. It is assumed that the full amount of 1200 Mt of CO2 could be injected if the initial injection rate was ramped-up rather than suddenly commencing at 2 Mt year per well as in these simulations (injection rate is controlled by bottom hole pressure at the injection wells, which is affected by a relative permeability-related pressure increase at the onset of injection). Figure 5 shows the CO2 saturation and pressure change following injection.

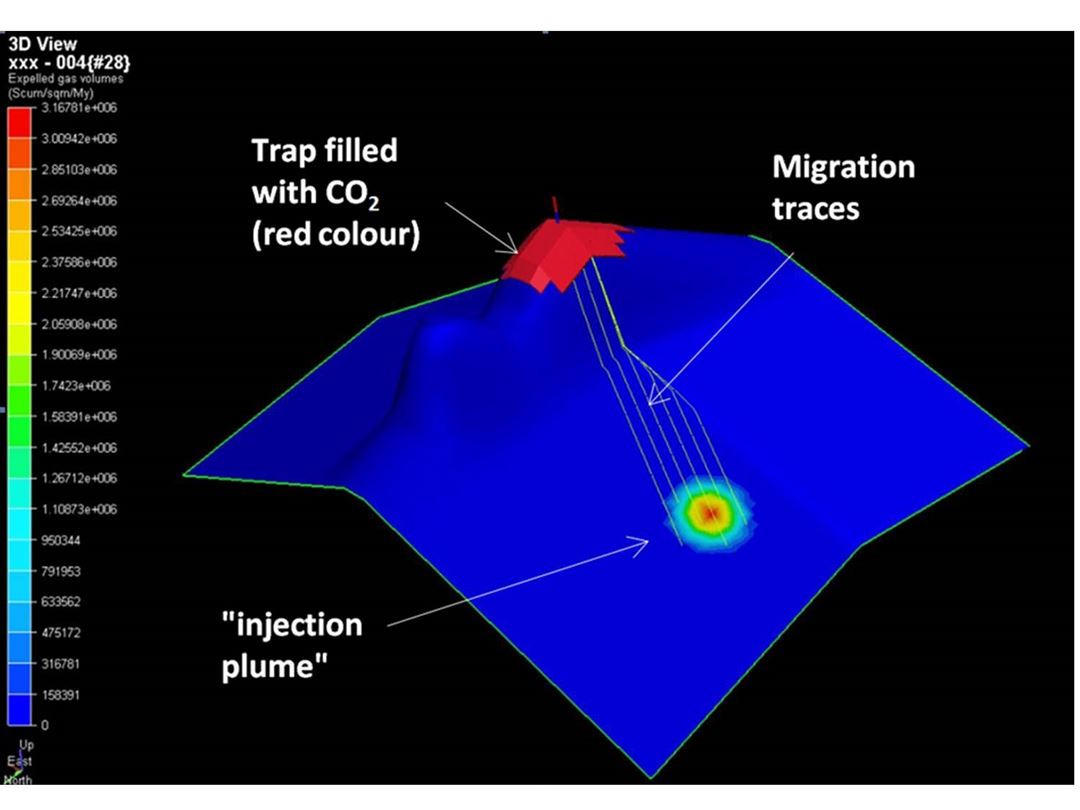

In the updated basin modeling tool SEMI CO2 Demo version, cap rock leakage routines for CO2 within trap structures have now been included. This is illustrated in Figure below showing the migration traces from the plume to the trap filled with CO2.

Related publications

- Effects from boundary conditions and input functions on dynamic capacity estimation

- Synergy Benefits in Combining CCS and Geothermal Energy Production

- Faulting in prospective CO2 storage sites in the UK southern North Sea

- Trapping Effects of Small Scale Sedimentary Heterogeneities

- The capability of faults and top seals in the Bunter sandstone of the UK Southern North Sea to seal carbon dioxide

- Regional model development and study of pressure propagation

- Simultaneous CO2 injection and water production to optimise aquifer storage capacity

- The impact of boundary conditions on CO2 storage capacity estimation in aquifers

- The Impact of Boundary Conditions on CO2 Capacity Estimation in Aquifers

Storage Behaviour (2009-2013)

Overall objective:

The main objective was to provide an improved physical and practical basis for determining best practice for CO2 storage.

Contribution to one or more of the overall goals/objectives of BIGCCS

The various trapping mechanisms for CO2 in the underground are structural trapping (i.e. existence of a cap rock), capillary trapping, dissolution into brine, and so-called chemical trapping. Dissolution is a generally an important medium to long time scale mechanism, potentially removing all possibilities of long term leakage from a storage site. The work in BIGCCS improved the basic understanding and especially the timing of this trapping mechanism, which is important for qualification and storage safety.

Major achievements

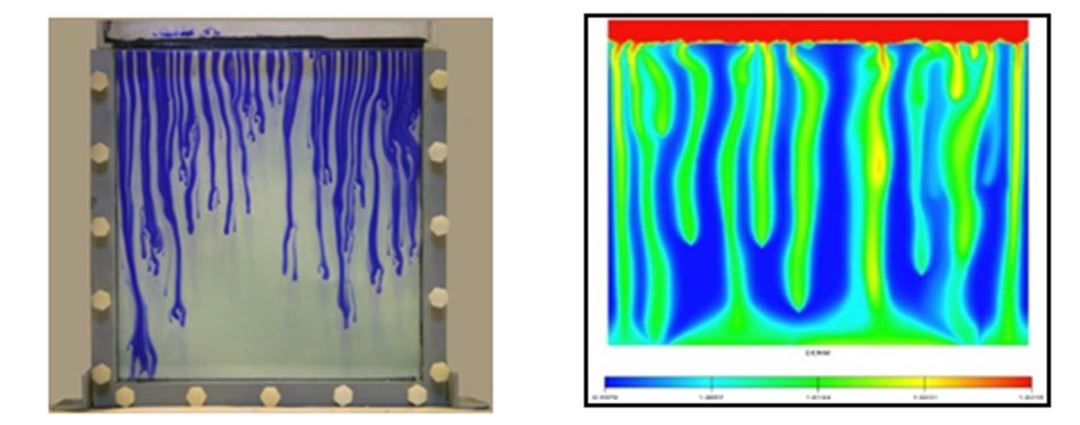

New mathematical results on gravitational driven instabilities of CO2 – brine solutions. In particular, the instability operator was explicitly derived, and novel properties on the spectrum of this operator highlight properties of the onset of convective mixing. Upscaling of dissolution mechanisms, as well as experimental and numerical studies of convective mixing in homogenous and heterogeneous porous media were also studied in this Task.

Related publications

- Simulation and Experimental Investigation of Different Phenomena in CO2 Storage in the Saline Aquifers

- Miscible and Immiscible Gas Injection for Enhancing of Condensate Recovery in Fractured Gas Condensate Reservoirs

- Simulation Study of Density-Driven Natural Convection Mechanism in Isotropic and Anisotropic Brine Aquifers Using a Black Oil Reservoir Simulator

- The effects of anisotropy and heterogeneity on CO2 dissolution in deep saline aquifers

- The gravitational instability of a diffusive boundary layer; towards a theoretical minimum for time of onset of convection

- Experimental and simulation studies of density-driven-convection mixing in hale-shaw geometry with application for CO2 sequestration in brine aquifers

- Upscaling studies of diffusion induced convection in homogeneous and heterogeneous aquifers