– Our technology can reduce the need for maintenance by up to 80 percent, while keeping assets safer than today, resulting in major savings for the industry. At the same time, it reduces environmental impact and lowers the number of on-site working hours, reducing the risk to personnel, says Jon Magne Johansen, who has worked 18 years at SINTEF and is now becoming CEO of Previse Technologies.

For SINTEF, the establishment of Previse Technologies is a clear example of how research delivers direct value to industry.

– We are proud that Previse Technologies is now becoming a reality. It shows how our research and laboratories contribute to solutions with global potential. When a research idea grows into a company, it underlines the importance of our role in the innovation chain, says Inge Gran, CEO of SINTEF Energy Research.

A “weather forecast” for water in insulation

A medium size process plant contains so much piping that the total length equals a round trip from Paris to Berlin. Most of these pipes are insulated to save energy, reduce noise, or provide fire protection. But under the insulation, water can enter and create hidden corrosion – which in worst-case-scenarios leads to leaks and accidents. This is known as corrosion under insulation (CUI). Over the past 40 years, CUI has been responsible for 20% of major process plant incidents in the EU.

Today, CUI maintenance is carried out “blindly.” Large amounts of insulation are removed in search of damage, but well beyond half of this work turns out to be unnecessary. This results in billions of Euros in costs of unneccesary maintenance, large quantities of waste, and avoidable climate impact.

– Previse Technologies makes targeted CUI maintenance possible. This allows us to ensure safety at process plants while avoiding the disposal of perfectly usable insulation and cladding. It also reduces the need to send large crews into facilities, lowering the risk of personnel being injured, says Johansen.

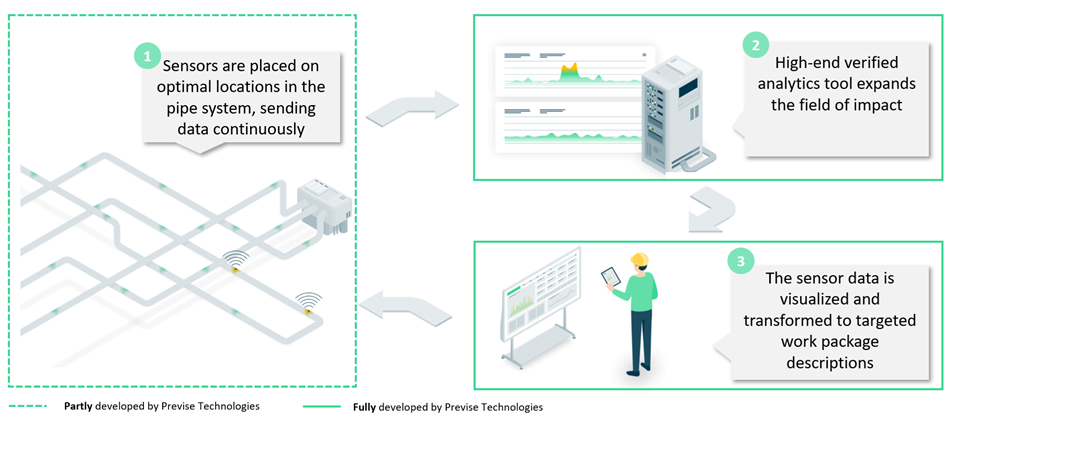

The technology resembles a kind of weather forecast, predicting the water conditions in the insulation. Smart sensors detect where water is present, while advanced physics models and statistical tools analyse how the water moves. This way, maintenance can be directed precisely to where corrosion is most likely to occur, without having to remove insulation for inspection.

From lab to reality through the Research Council of Norway

– The collaboration was born during a meeting on carbon capture, when Shell challenged SINTEF to develop a sensor-based method for detecting hidden corrosion. SINTEF Energy Research, with its expertise in flow dynamics and algorithm development, took on the challenge, explains Johansen.

Through the research project Predict CUI, which received support from the Research Council, and subsequent industry projects (IPNs), the solution was developed and tested in collaboration with Shell, Equinor, and Gassco.

– The support from The Research Council of Norway through Knowledge-building projects and Innovation projects has been crucial in maturing the technology. Thanks to these support schemes, we have been able to take the research idea all the way from the laboratory to a market-ready solution, says Johansen.

Global market for monitoring insulated pipes

SINTEF’s commercialisation company, SINTEF TTO, has led the work of establishing Previse Technologies.

– Our task is to build a bridge between research and industry. Previse Technologies is a good example of how we commercialise a strong technology from SINTEF by creating a solid company with the potential to succeed internationally. The work leading up to the establishment of such a company includes developing a sustainable business model, recruiting a strong team and board, and bringing in quality investors, says Asle Hovda, Investment Director at SINTEF TTO.

– This is why we are actively involved in the company’s foundation through our investment fund SINTEF Venture VI and are planning further investments, says Hovda.

The technology developed by Previse Technologies is relevant for all industries that use insulated piping systems – from oil and gas to the chemical process industry, CO₂ transport, hydrogen, and district heating.

– This is a technology I care deeply about as it reduces costs, increases plant safety, and delivers major environmental benefits at the same time. This combination is crucial for ensuring that industry remains both competitive and sustainable in the future, and it will have significant impact both nationally and internationally, says Inge Gran, CEO of SINTEF Energy Research.

- SINTEF TTO is SINTEF’s commercialisation company and manages SINTEF Venture VI.

- SINTEF Venture VI: Early-stage investment fund that invests in companies spun out from SINTEF. 517 million NOK in committet capital. Read more about SINTEF Venture VI (in Norwegian).

- SINTEF Energy Research

- Previse Technologies