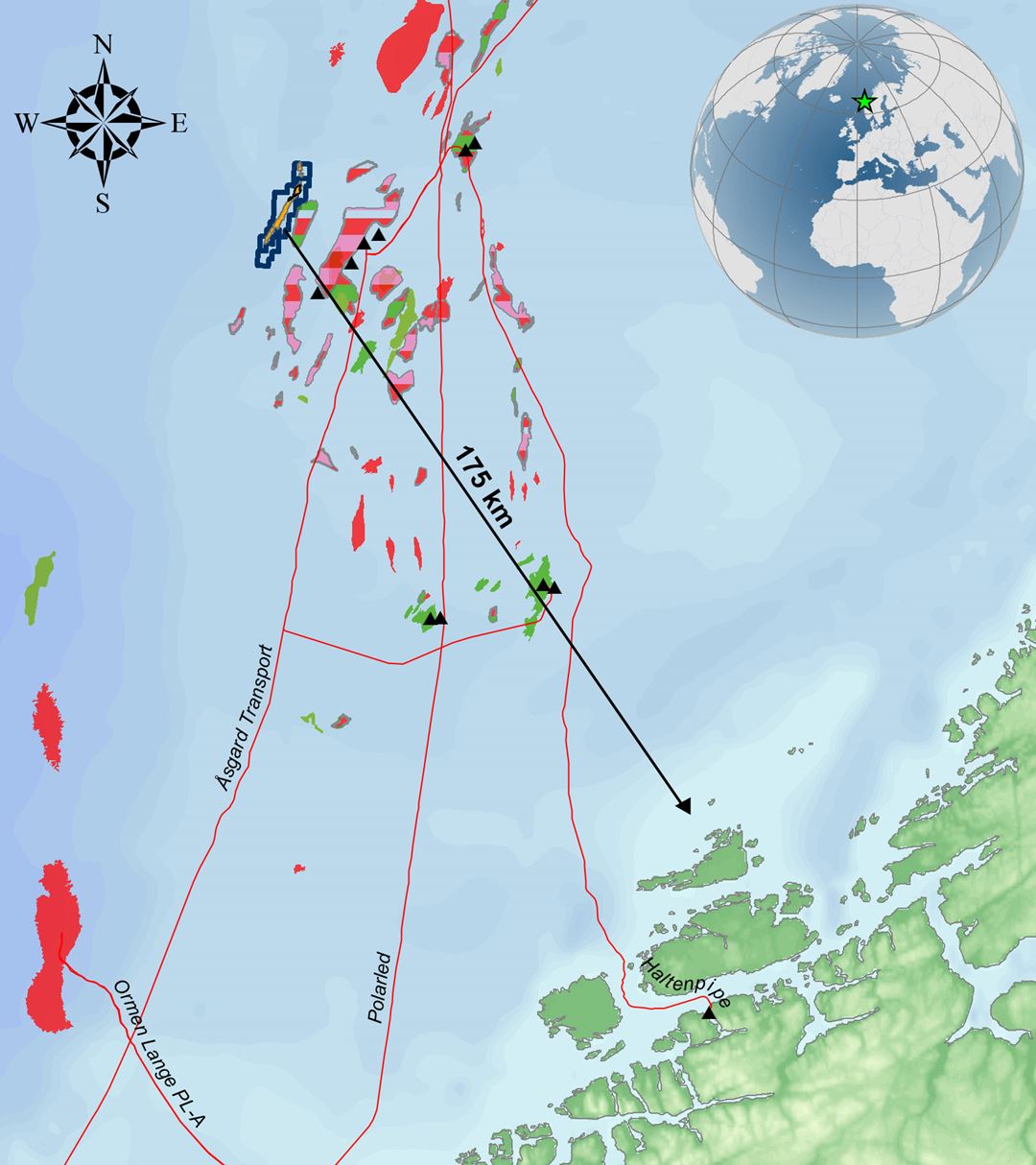

The Berling field (formerly known as Iris Hades) is a gas and condensate field in the Norwegian Sea. In the period 2023-2028, the field will be developed and tied to the existing infrastructure of the Åsgard B platform. The development has a total sum of more than 9 billion Norwegian kroner.

In the planning of the development, OMV have looked for various alternatives for savings and risks.

– The field has a planned lifetime of seven years. Since the operating time is short, it is necessary to make the development as profitable and climate-friendly as possible. The development of the Berling field is complex and extensive. Three wells will be drilled and a 24 km long pipeline will be laid on the hilly seabed. We wanted to see how we could do this in the best possible way, says Luca Garzonio, lead operations engineer at OMV.

OMV chose to engage SINTEF to confirm their theoretical models that heating cables could be excluded without the risk of the pipes being "plugged". A major challenge in the production of oil and gas on the seabed is that ice-like structures, called gas hydrates, can stop the flow in the pipes if the production stops. This happens if the temperature gets too low.

There are several ways to avoid gas hydrates, where the installation of heating cables in pipelines was identified as the safest. However, all options have a large financial cost.

– Omit heating cables will not only make the installation easier, it will also result in major cost savings for us. Roughly speaking, we will save 20 percent of the total investment costs for the subsea part. In addition, there are savings due to less complex offshore operations when the pipelines are to be laid, says Luca Garzonio.

«Movable» hydrates at the Berling field

Whether hydrates are formed or not depends on various factors and will vary from field to field. Temperatures on the seabed and pressure in the pipeline play a role. In addition, the properties of the oil and the water phase produced affect.

Martin Fossen, senior researcher at SINTEF, is part of the team at the Multiphase Flow Laboratory at Tiller, which has conducted research on hydrate formation for the Berling field. With a flow wheel, they have reproduced the actual conditions of the field: with the same oil and gas mixture, the same water chemistry, temperatures, pressure and flow conditions in the pipe.

The experiments showed that it will, most likely, be possible to start up after a production shutdown, without hydrates being formed.

– They also showed that even though the temperature in the Norwegian Sea is relatively low, the pressure in the pipeline is not very high, which means that the amount of hydrate formed is not so big. Hydrates formed at the Berling field are unlikely to «solidify» and plug the pipes. Instead, they become «movable», so that the oil mixture can still pass through the pipe without any problems," says Martin Fossen.

Less emissions, less materials and lower energy consumption

– SINTEF's research has shown that our theoretical models are too conservative and that it is not necessary to install heating cables out to the field, says Jan Kåre Risbakken, senior production engineer at OMV.

– When we start up the wells and pipeline after a longer production stop, the line will have a very low temperature. With SINTEF's studies, we confirmed that we could get out of the «hydrate zone» by lowering the pressure as far down as Åsgard B allows, while pumping methanol into the pipeline and carefully starting up the wells, he explains.

The decision will not only give OMV financial savings, it will also help reduce their CO2 footprint.

– This will result in lower emissions in conjunction with the installation, less amount of materials and lower energy consumption during the development of the field. Our calculations show that the field now will emit significantly less CO2 than a pipeline that needs heating cables, says Luca Garzonio.

Positive effects for the Norwegian continental shelf

SINTEF has done research on gas hydrates for oil companies all over the world for more than 30 years. The research has had a direct impact on decisions that have resulted in safer production, and major cost savings for companies – in addition to important contributions to the environment. Several of SINTEF's research projects have been funded by the Research Council of Norway. An ongoing project led by SINTEF at the Multiphase Flow Laboratory at Tiller is "New Hydrate Management".

The knowledge SINTEF now has obtained for OMV can have effects far beyond the Berling field. If other companies can make the same assessment, based on research from SINTEF, existing and new fields can be developed in a more efficient and cost-saving way, without compromising safety.

– Hydrate formation should be looked at for each field, in relation to the risk and costs of accepting hydrate formation, if the production is shut down for a period, says Martin Fossen.

Gasshydrater er dessuten en av teknologiene som kan brukes til å fange CO2, gi effektiv kjøling og til vannrensing. Dette viser at utfordringer og løsninger for oljeindustrien gir kunnskap som kan overføres til nye miljøvennlige teknologier.

Gas hydrates are also one of the technologies that can be used to capture CO2, provide efficient cooling and for water purification. This shows that challenges and solutions for the oil industry provide knowledge that can be transferred to new environmentally friendly technologies.