The Norwegian Public Roads Administration has been toying with this idea for some time: if noise-barriers are mounted directly on roadside guardrails, they can use existing foundations and posts, thus eliminating the cost of installing such elements all over again.

Crashes simulated on computers

- As participants in the national research centre SFI SIMLab, NTNU and SINTEF have developed mathematical models that show how vehicles and guardrails behave in the event of a collision.

- SINTEF used these modelling tools in its project for the Norwegian Public Roads Administration. Click on the video to watch a visualisation of the results of a simulation. When a collision takes place, the noise barrier either moves backwards together with the guardrail or is knocked over, depending on whether or not it has been manufactured and installed correctly.

- Today, it is quite usual to employ computer simulations of this sort in the design and evaluation of how guardrails behave. This procedure is much less expensive in terms of time and money than physical testing, assuming that the model is already available.

Several types of guardrail are used on Norway’s highway network. Railings on road bridges, for example, are designed to keep cars actually on the road, so these are not subject to the same requirements regarding yielding to the force of a crash as other types of guardrail.

Many “stiff” guardrails already incorporate noise barriers, but the Public Roads Administration is now looking for a combined solution for yielding guardrails, which are the most common type of guardrail in use in Norway.

Aluminium panels

Yielding guardrails absorb forces from collisions in order to reduce injuries. How can noise-barriers be integrated into guardrails, and what materials should be used in them? The Public Roads Administration asked SINTEF to look into these questions, with the aim of ensuring that the design of these rails will satisfy guardrail requirements.

SINTEF has now presented its analysis of one chosen solution concept, where aluminium panels are incorporated in the rails to act as noise-barriers.

Ideal material properties

“Aluminium is corrosion-resistant, the material is widely used in energy-absorbing systems in many applications and it can easily be worked and recycled. It has a good ability to reflect sound, and transporting it is also energy-efficient because it is light in weight,” says SINTEF scientist Dirk Nolte.

In the hunt for good designs, Nolte’s colleague Nguyen Hieu Hoang used a computer model to simulate what happens when vehicles collide with a yielding guardrail with a built-in noise-barrier.

An example of how things are done today. Ordinary guardrails and noise-barriers are not usually incorporated in a single construction. Combining the two reduces costs because the noise-barriers use the existing guardrail posts. Photo: SINTEF/Thor Nielsen

“The combi-rail needs to have sufficient stiffness and at the same time sufficient ability to absorb energy that it satisfies current requirements for the protection of drivers and passengers in the event of a collision. Thanks to our tests on models, we can be sure that our proposals lie within these limits,” says Hoang.

Applications in sloping terrain

The results of the analysis employ panels that match the height of the guardrail, which means that the barriers are no more than around 75 cm high.

Responding to those who do believe that this solution will not provide adequate noise control, Magnhild Finnanger, a senior engineer with the Norwegian Public Roads Administration, Eastern Region, offers the following explanation:

“Yielding guardrails are often sited where the terrain falls away from the road. On such stretches of road, many houses therefore lie below the level of the source of noise. Such houses can obtain effective noise protection even from low noise-barriers that are located at road level. Guardrails can also provide a certain amount of noise reduction to house that lie just slightly below the road, and in such cases, they can act as one of several noise-reduction measures.”

SINTEF Building Research scientist Nathalie Labonnote, a participant in this project, says that the nearer to the source of noise a barrier is located, the lower it can be. She emphasises that the combined solution will not be suitable for all stretches of road with guardrails, and that detailed noise estimates will have to be produced in order to predict the efficacy of the solution.

Can protect overturned two-wheeled traffic

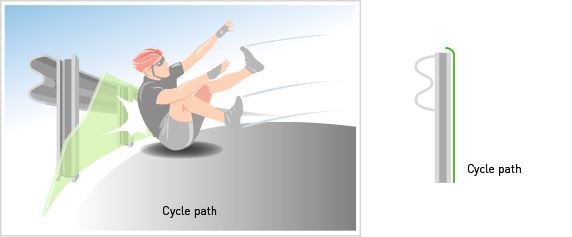

Help for overturned cyclists

- Aluminium panels (coloured green in the illustration) on the rear face of the guardrail posts, are the standard solution proposed by SINTEF for mounting noise barriers on guardrails.

- As well as damping noise, this solution will prevent cyclists from colliding with guardrail posts when they overturn on a cycle path behind the guardrail.

- Noise barriers need to weigh at least 20 kg per square metre to provide adequate noise damping. If aluminium is used, the requirement is met by using a single eight-millimetre-thick panel.

Illustration: SINTEF/ Knut Gangåssæter

Yielding guardrails are made of steel profiles. In addition to their impact-reduction abilities they are also intended to prevent vehicles hitting obstacles, rolling down steep slopes or ending up in rivers.

According to Nolte, if noise barriers are installed, they can also improve road safety for two-wheeled drivers (see fact-box).

“We have placed the noise-barriers in such a way that they are mounted behind the guardrail post for the sake of simplicity. As well as reducing noise, this configuration can prevent cyclists who fall on the cycle path behind the rail from hitting posts. However, we also envisage a solution in which barriers are installed on the front of the posts, that is, on the side facing the road. Such a design would prevent overturned motor-cyclists from colliding with pillars,which may result in a lethal type of impact.”

Ready for testing on road

According to senior engineer Finnanger, the Public Roads Administration intends to start with testing designs that have been validated through virtual testing by SINTEF’s computer model; that is, with noise-barriers mounted on the rear of the guardrail posts.

“How long will it be before we see the first combined guardrails and noise-barriers on Norwegian roads?”

“SINTEF is currently trying to bring in a Norwegian company to produce noise-barriers for trial installations on certain stretches of road. As the public authority concerned, we want to see that all the technical specifications laid down by the report are open, as this will make them equally accessible to any company that wishes to produce such barriers,” says Magnhild Finnanger.

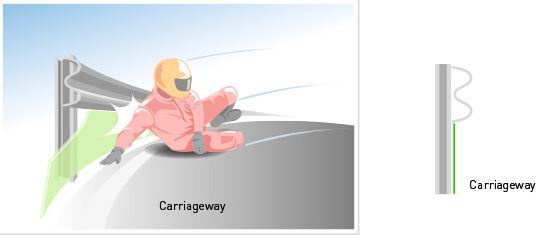

Collision protection for motorcyclists

- As an alternative to the standard solution, SINTEF proposes that the aluminium noise barrier could be installed on the side of the posts facing the road.

- As well as damping noise, this solution would prevent motorcyclists from colliding with the guardrail posts.

- SINTEF has also outlined a third alternative, comprising thinner panels mounted on both sides of the posts, and where the front-facing panel is perforated and the space between the panels is filled with ground-up tyres or other sound-damping material. As well as damping noise, this version would protect both cyclists and motorcyclists.

Illustration: SINTEF/ Knut Gangåssæter