Research group Batteries and Hydrogen technologies

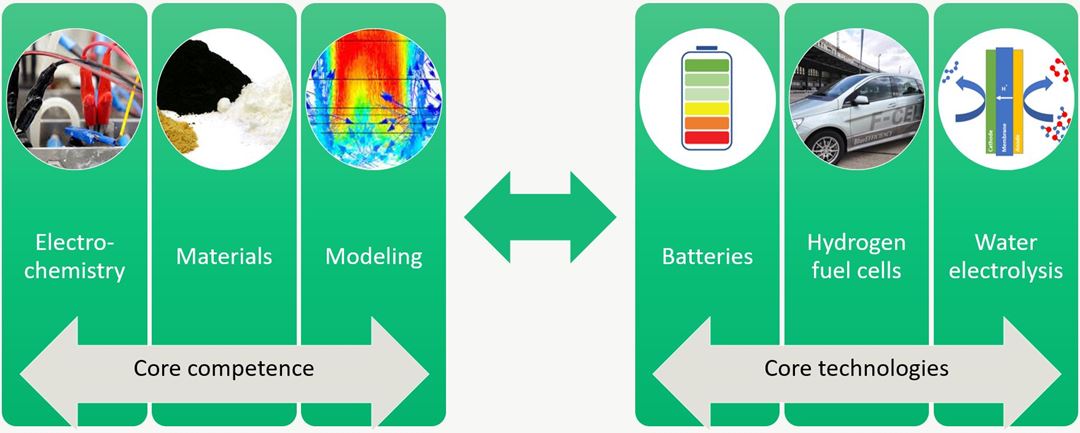

Our goal is to develop new technology for green energy solutions based on a high level of competence within materials and electrochemistry, using both modeling and experimental methods.

Contact person

Research areas

Hydrogen

- We work with low temperature electrolyzers and fuel cells. We develop new materials including catalysts, electrodes, porous transport layers (PTLs), microporous layers (MPLs), membranes and bipolar plates, and test their performance and lifetime under relevant real-world operating conditions.

- Advanced infrastructure such as test stations and supplementary electrochemical analysis equipment allows us a full understanding of the processes and degradation mechanisms occurring in-situ at a single cell and stack level.

- We are able to conduct short- and long-term tests for PEM fuel cell and electrolyzer single cells and stacks, as well as classical alkaline and AEM electrolyzer single cells.

- Post-mortem analysis of fuel cells and electrolyser components.

Batteries

- We develop materials, electrode structures and electrolytes for next generation batteries including advanced Li-ion, metal air and solid state technologies.

- Our new battery laboratory and existing premises includes over 300 tests channels, special test set-ups for solid state battery research allowing us to gain better understanding of performance parameters and degradation occurring inside the battery cells.

- Paired with excellent physicochemical characterization we become a lead player in the European battery R&D landscape.

Modeling

- We develop computational models of fuel cells, electrolyzers, and batteries to gain greater insight into the physical processes that drive performance gains in cells, packs/stacks, and systems. We use these models both to pursue research questions and to help industrial partners design products, and we are involved in developing open-source software for the scientific community as well.

Research approach

World class, unique infrastructure financed by both INFRA and SINTEF

- Hydrogen lab

This low temperature hydrogen laboratory is one of the most complete and advanced laboratories for electrolyser and fuel cell testing in Scandinavia. It offers testing capabilities for both electrolysis and fuel cells from R&D-scale single cell testing up to kW-scale short stack testing. The laboratory is shared with NTNU, and is one of the nodes of the Norwegian Fuel cell and Hydrogen Centre. - SINTEF Battery lab (Siemens Energy)

380 m2 lab area including a 150m2 dry room with a dew point of -42.5 °C. The lab houses a complete pilot line for battery cell manufacturing; slurry mixing/rheology, slot die/knife coating, calendaring, vacuum ovens, pouch cell assembly and formation. The lab also includes 3 gloveboxes, climate chambers and over 300 channels (0-6V, 5Ah-60Ah) for testing small and large battery cells.

A project portfolio ranging from large competence building projects in the EU to industry projects with customers from all over the world enables us to build crucial competence and develop innovative solutions.

Employees in the research group for Batteries and Hydrogen technologies