The spare parts can then be produced on demand, and they can also be produced locally. You can then avoid having a large warehouse of spare parts, and instead establish a digital warehouse. Spare parts can be made quickly ny AM, without the need for e.g. tooling. For expensive materials, AM can provide cost savings compared to machining, if a large amount of material has to be removed in the machining process. Additive repair is another option. This can then be on-site or in a company with specialized equipment.

Repair and spare parts can be expensive when it comes to infrastructure availability, unplanned downtime, and long production lead times when spare parts are out of stock.

Therefore, "on-site" and "on-time" repair and maintenance solutions will be of great benefit. This will enable cost-effective maintenance and reduced production lead time.

In the longer term, it is possible to analyze the supply chain and the causes of error, and on this basis exploit the advantages of AM with regard to optimizing the (spare) parts and also merge multiple functions/parts into one part.

The challenges with AM of spare parts are partly the same as for AM in general, but there are also some more specific challenges, e.g. how to get the same material properties as in an old component that may not have a full specification available. To get the full effect of an "additive" spare part solution, it must be part of a digital supply chain.

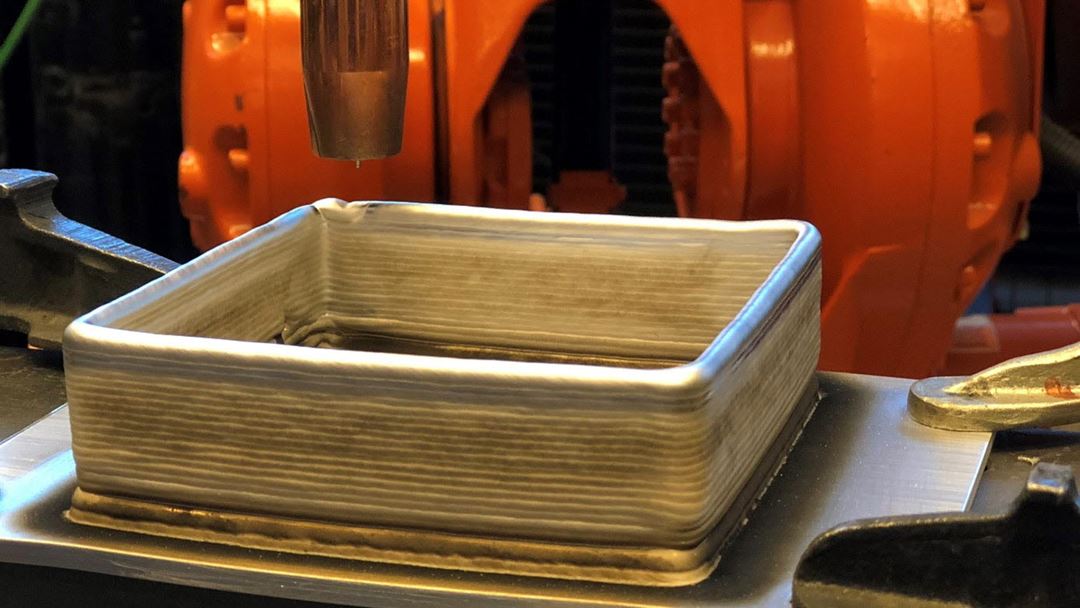

As an example, we can mention that SINTEF works with industrial partners to develop and implement AM for the repair and refurbishment of offshore components. The material requirements in the oil & gas industry must be met, and the new AM methods must provide a measurable cost reduction and reduced lead time. The project develops and optimizes AM techniques such as wire arc additive manufacturing (WAAM) and laser-based metal deposition (LMD), for repair and refurbishment of damaged components to extend their service life. Such solutions are relevant to many other industries, e.g. renewable energy, shipbuilding and the construction industry.

Contact persons:

Spare parts in general: Tor Dokken, Klas Boivie

Spare parts and repair (metals): Xiaobo Ren, Rune Østhus, Vegard Brøtan, Mohammed Mhamdi og Magnus Eriksson

Spare parts (plastics, rubber, composites): Erik Andreassen