3D bioprinting employs soft biocompatible materials together with cells, drugs or growth factors to create 3D structures for medical use and biological research.

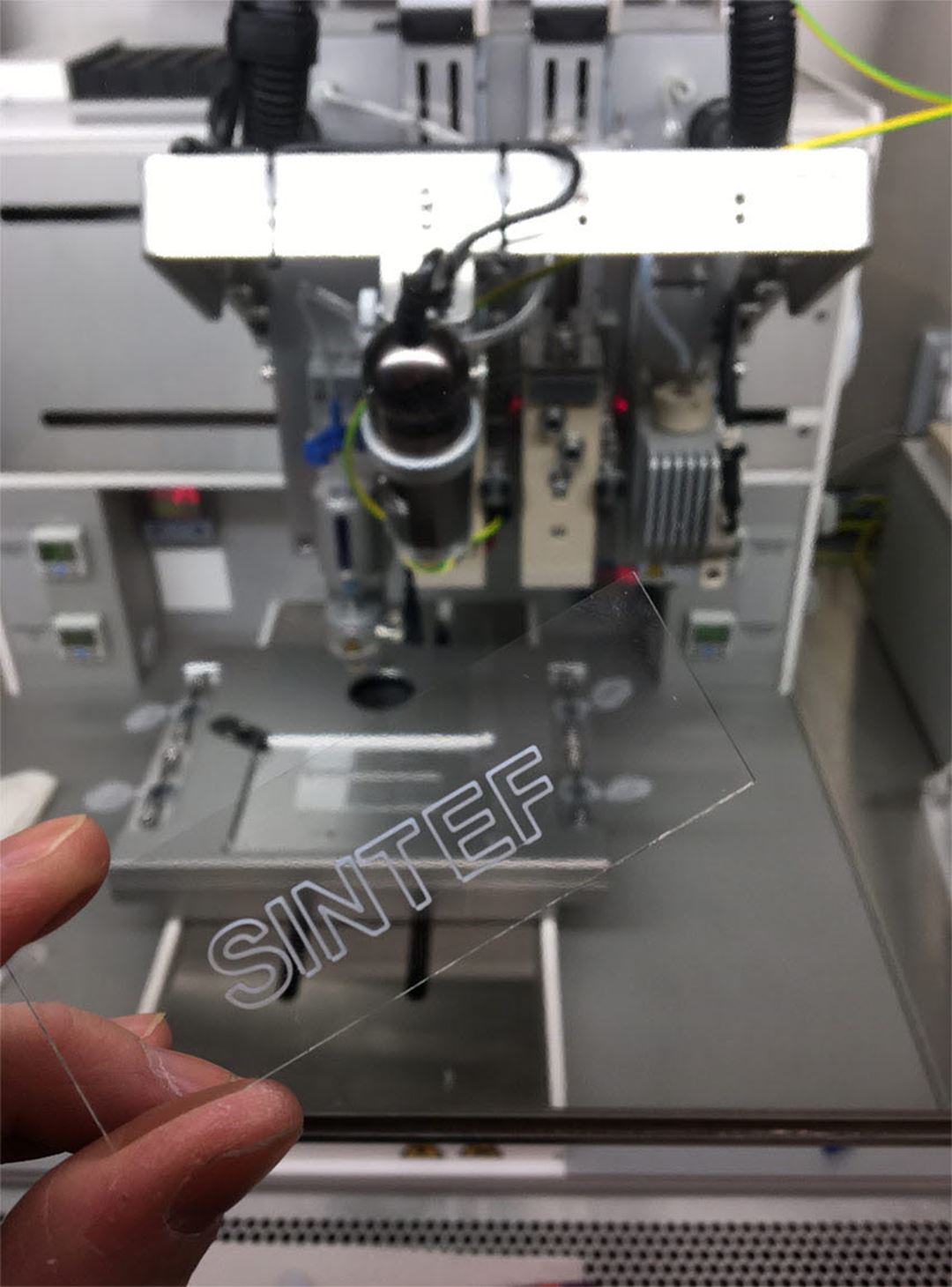

At SINTEF we work with all stages of production: 1) development of materials (feedstock) for printing; 2) culturing of cells; 3) printing of structures with materials and cells with our bioprinter; and 4) evaluation of the resulting structures and cells, using chemical, physical, and biological analysis methods.

The printing of 3D structures with living cells is closely linked to our biological screening platforms, with effective analysis of biological activity and effect, chemical analysis of e.g. metabolites and nutrients, and imaging with optical and confocal microscopy.

Other medical applications and additive manufacturing in general: Our screening platforms can also be used for products and materials produced via AM with other materials, for antibacterial properties and biocompatibility.