We take a cautious approach when selecting analytical methods for interpreting sensor data. This is because there are fundamental limits to the information that can be extracted, given the inherent noise and constraints of sensor systems. Our role is to understand where those limits lie.

While it's increasingly common for developers to apply algorithms in search of patterns that may not truly exist, our strategy is different: we prioritize improving data quality and information content through deliberate, well-informed sensor system design. A deep understanding of measurement physics is central to this process—both theoretically, through knowledge of fundamental principles and limitations, and practically, through expertise in instrumentation, optics, embedded electronics, and field testing.

We also employ numerical physics simulations to model the properties and behavior of the systems we design. In many cases, traditional data analysis techniques, such as multivariate statistics, are sufficient for interpreting sensor outputs. However, when appropriate—particularly in cases involving multimodal data (e.g., spectral, thermal, spatial, textual)—we collaborate closely with AI experts to apply deep learning methods effectively.

We avoid “squeezing” weak insights out of weak signals

Today, the ubiquitous data coming from a large number of low-cost imaging sensors and other measurement devices is fuelling numerous deep learning projects. While often resulting in apparently impressive and powerful predictions and estimates, many of these give black-box (or unexplainable) predictions, and there are many cases where the results are limited by the relevance or the signal-to-noise ratio in your source data.

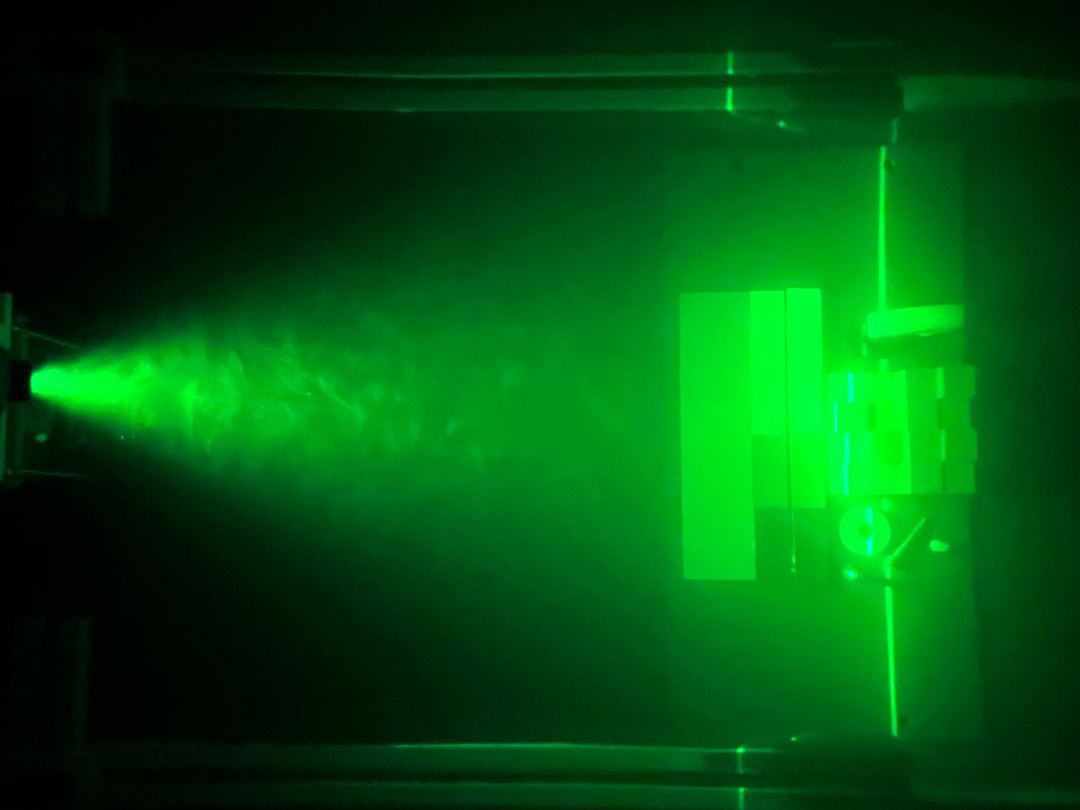

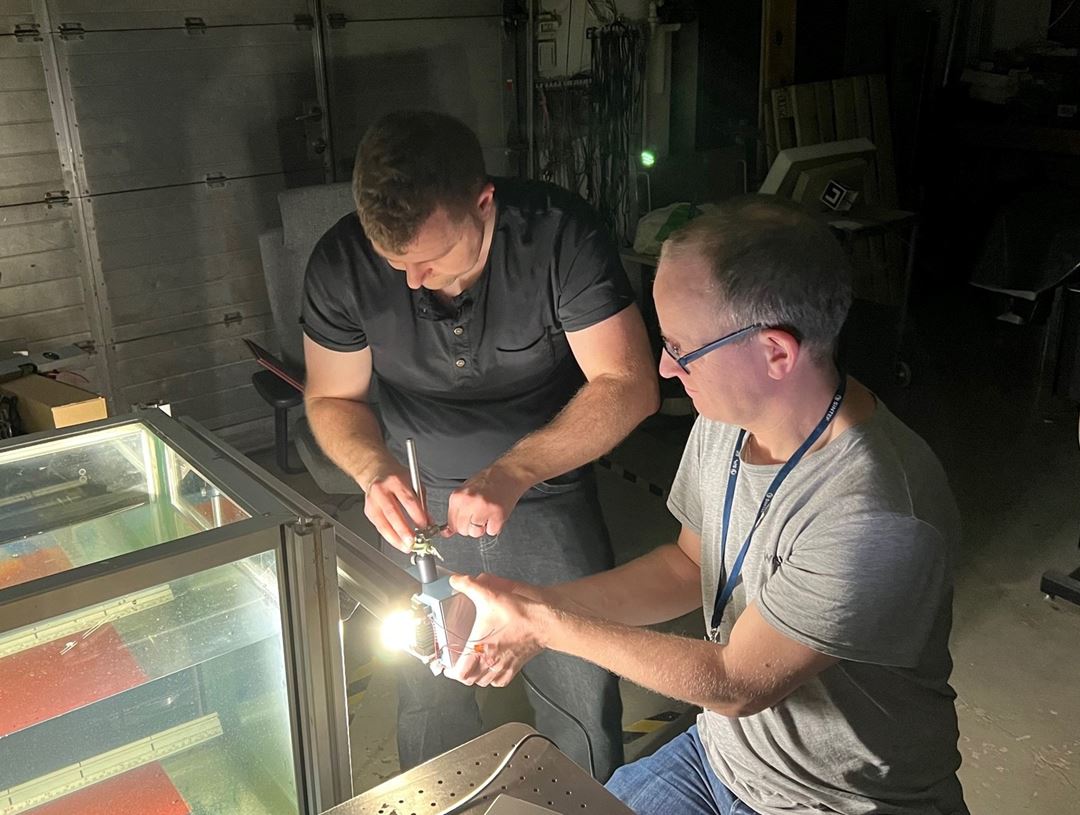

Fortunately, just like LegoTM bricks, there are many elegant solutions and possibilities for building customized, new measurement systems based on off-the-shelf optical components. In the Applied Optics group, we take methods and principles normally found only in academia and expensive laboratories, and implement them in novel, practical measurement systems for commercial, industrial, or agricultural use. Often, a smart modification or addition to a standard off-the-shelf sensor is sufficient to increase the relevance or signal-to-noise ratio by orders of magnitude. Increasingly, we are also exploring AI-driven design and optimization of sensor systems, using machine learning not only to interpret data, but to guide the configuration of sensing modalities, feature selection, and system architecture.

In general, we take an application-driven, top-down approach—starting with the user’s need and identifying the best available technology. However, when no existing commercial components can meet the requirements, we can work bottom-up by drawing on our in-house microfabrication expertise at MiNaLab, where our colleagues have over 20 years of experience developing and manufacturing solid-state and MEMS sensor components.

There are many examples, from subsea all the way to Space, where our physics-based approach has led to better quality data:

- A deep understanding of molecular spectroscopy and Fourier transform infrared spectrometry enables cutting-edge sensing systems, such as ANITA on the International Space Station for air quality monitoring.

- Underwater 2D and 3D imaging is significantly improved by accounting for turbidity in both illumination design and image processing, as demonstrated in UTOFIA and OceanTech.

- Fluorescence techniques can classify organic materials using smart and simple setups—like a laser diode, spectral filter, and standard camera—as shown in salmon lice detection.

- Interactance-based spectrometer design can probe food composition content and taste in foods from berries to live crabs, revealing information that standard reflectance imaging or spectroscopy cannot provide.