Rare earth elements are considered "key-enablers" of green technologies, as they are used in hybrid electric vehicles, wind mills, and highly efficient electric motors. The dependence on Chinese exports, makes Europe and western countries, in general, extremely dependent and vulnerable to Chinese market control. Therefore rare earth elements are considered to be materials with the highest supply-risk.

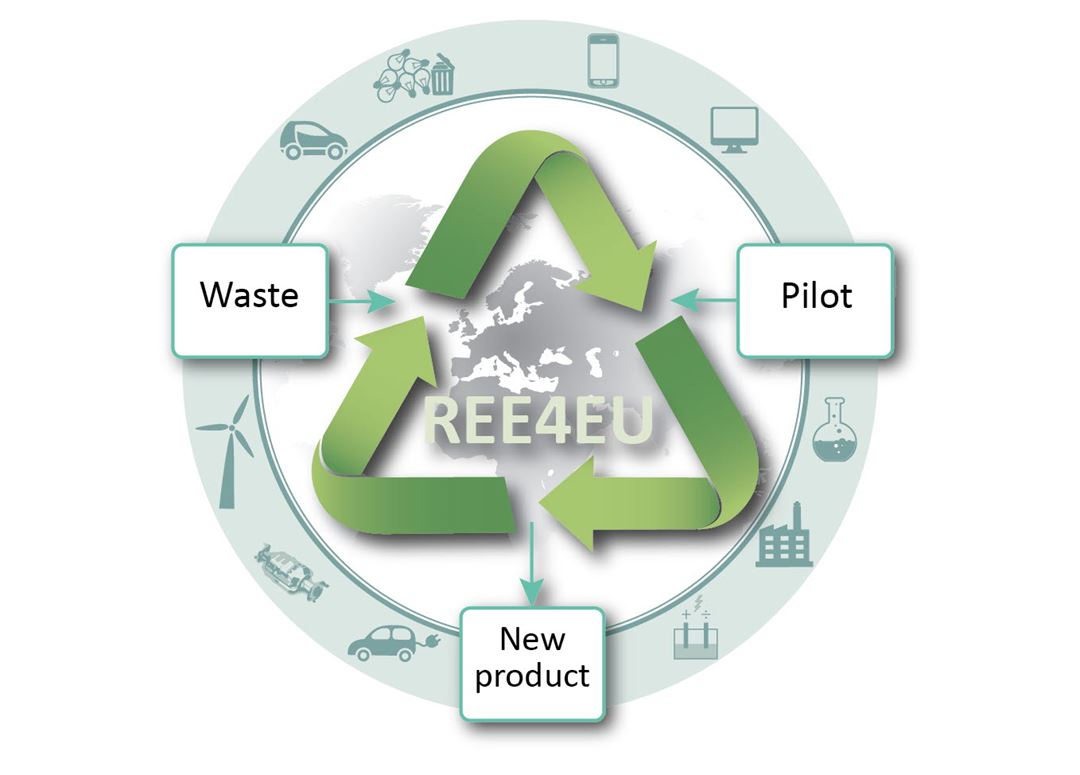

The REE4EU project will develop, validate and demonstrate in 2 industrially relevant Pilots an innovative rare earth alloys production route from permanent magnets and NiMH battery waste. REE4EU will open-up a fully new route bringing recovery of 90% of in-process wastes from permanent magnet manufacturing within reach. The targeted integrated solution will demonstrate dramatic improvements in cost and environmental performance compared to state of the art technologies. This includes avoidance of process steps, 50% energy savings, and 100% recycling of reagents as opposed to disposal of strong acid leaching agents in state of the art pre-treatment steps.

The project will prove technical and economic viability on in-process permanent magnet waste (swarf), as well as end-of-life permanent magnets and NiMH battery waste. REE4EU will also develop urgently required market data on end-of-life rare earth availability and a triple value-chain business case for a new European secondary rare earth alloys production sector. This will create new jobs, increase Europe's independence from imports and last but not least, provide valuable raw materials for fast growing European green-technology industries such as electrical/hybrid vehicles and wind turbines.

Partners

The REE4EU consortium consists of 14 partners from 7 European countries:

Norway: SINTEF, project coordinator; Elkem, world leading company for environmental-friendly production of materials.

Sweden: STENA Metall Group, focused on recycling, with operations in around 220 locations in 11 countries.

Germany: Vaccumschmelze, leading global and largest European manufacturer of advanced magnetic materials

UK: LCM, SME world leader in the manufacture and supply of rare earth based alloys and high purity metals

France: CEA, A3i-Inovertis, SME dealing with process design, engineering and LCA expert; SNAM, European leader in battery recycling; Paul Sabatier University

Spain: Tecnalia; Idener, SME dealing with engineering, ionic liquid extraction and advanced design and optimization tools.

Belgium. PNO Innovation, SME leading European expert on innovation management and funding; CEFIC, European Council for the Chemical Industry and process industry leader of the SPIRE initiative; AVERE, European association for battery, hybrid and fuel cell electric vehicles.

The project is part of the Horizon 2020-SPIRE-07-2015 Recovery Technologies for Metals and other Minerals, and has received funding from the European Union's Horizon 2020 research and innovation programme under GA No. 680507.