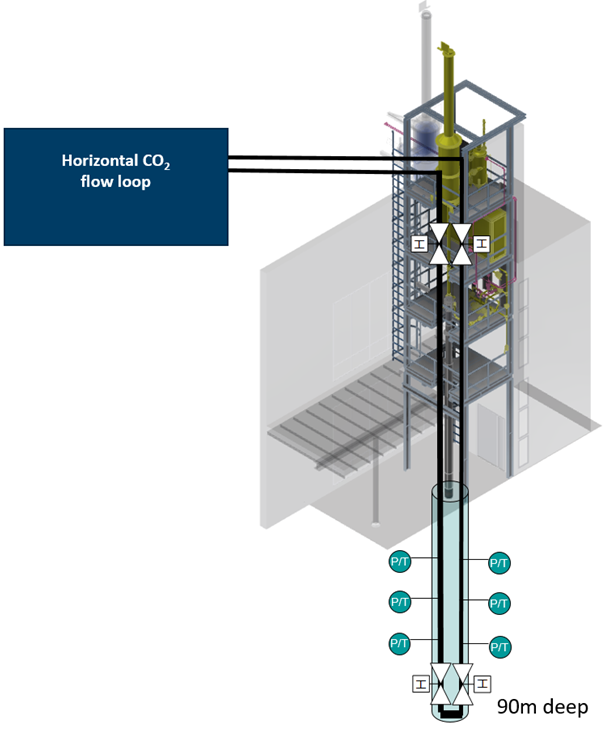

DeFACTO is a vertical flow facility that enables the circulation of CO2 through a 90 meters deep U-tube loop (depicted in the figure). The loop is instrumented with over 100 high precision-fast response pressure and temperature sensors, allowing to measure pressure waves with a high degree of accuracy.

The vertical flow loop is connected to a 139 meters long horizontal flow loop, located on top of the facility. The horizontal flow loop enables circulation of CO2 with precisely controlled parameters (contaminants, temperature, pressure, gas to liquid ratio).

The CO2 is then circulated through the vertical loop where its behaviour can be analysed at different depths. Each tube in the U-loop can be isolated and pressurised or depressurised individually.

The data collected help understanding when and how the CO2 freezes under depressurisation, cavitation phenomena, two-phase and transient flow behaviour, and ultimately assist engineers in the design of safer and more efficient CO2 transport and storage systems.

Experiments that can be performed through DeFACTO both with pure CO2 and with impurities (N2, up to 20% CH4)

- Both single and two phase flow.

- Steady state flow at different T/P conditions and gas to liquid ratios.

-

Transient:

-

Shut in and first fill

-

Depressurisations

-

Blowouts

-

Fluid hammers

-

-

Estimation of heat transfer coefficient under controlled conditions.

-

Reservoir backflow.

Datasheet, DeFACTO flow loop (EX-proof).

- U tube largest ID, 32 mm smallest ID, 16 mm

- Pressure, FV to 160 bar

- CO2 process temperature, -60 to +60 C

- Controlled temperature in hole, 5 to 35 C

- Design flow, 10 kg/min (0.2 kg/s)

- Ready for water injection (well control and hydrates formation investigations) to increase understanding of interaction between CO2 rich well flows with reservoir water.

Questions we can answer:

How much will a depressurisation cool the pipe?

- Current pipelines are designed to -78C, which requires at least a 3.5 Ni steel. Up to -60 C fine grain steel can be used, reducing the cost of the pipeline.

Will dry ice / hydrates form during depressurisation?

- The formation of hydrates during depressurisation helps defining how dry the transported CO2 must be, which can reduce the cost of CO2 dehydration.

- Pressure profile and Joule Thomson effect during leakages and emergency depressurisations determine the temperature design of the transport system.

Will water hammer effects be significant when closing valves?

- Pressure surges inside the lines determine the design pressure of the pipeline, driving the CAPEX.

The project builds on earlier BIP project CO2 IT IS competence and infrastructure.

SINTEF is responsible for constructing the facility at Gløshaugen in Trondheim and executing the experimental campaign. SINTEF contributes with expert knowledge on infrastructure design of CO2 transport systems and modelling and simulations of pipe dynamics, as well as fluid properties. In-house codes for fluid dynamics and thermodynamics are used for planning, design verification and comparison of results.

DeFACTO is a CLIMIT Demo project which is partially funded by Gassnova, SINTEF Energi AS, Equinor ASA and Total E&P Norge AS are partners.