Project Manager TwinYards

Erlend Alfnes

Urgent need for increased knowledge

A high number of offshore wind turbines is expected to be built, installed, operated, and decommissioned over the next decades, constituting a critical element in the green shift. This offers numerous opportunities for the Norwegian yard industry. Norway leads globally in maritime equipment design and production, with unique expertise and infrastructure, providing a solid foundation for success in offshore wind. However, the success relies on more efficient yard operations. The Norwegian yard industry's lack of cost competitiveness and productivity has been stressed previously, and even though there are signs of improvement, their effectiveness should have been much higher. They need to reduce costs by 10-15 per cent to win newbuild orders in the long run and be able to contribute to the cost efficiency improvements required for a profitable offshore wind industry. There is, therefore, an urgent need for increased knowledge on efficient operations of the yards.

Digital twins and artificial intelligence have been successfully used in manufacturing to reduce costs and improve efficiency. In the yard industry, the use of digital models has primarily been from a product perspective. There is a lack of knowledge on how they can support efficient planning of the people, equipment, and infrastructure at yards. With digital twins and artificial intelligence, yards gain access to robust data and analytical capabilities that provide more detailed and accurate plans and schedules that minimize non-value adding activities, promising a significant reduction in non-value adding time.

The overall objective of TWinYards is to develop knowledge on how to achieve resource efficiency and flow in the Norwegian yard industry by exploiting digital twins and artificial intelligence. The yards will thereby be able to reduce costs and contribute to green yard operations and a sustainable shift towards offshore wind.

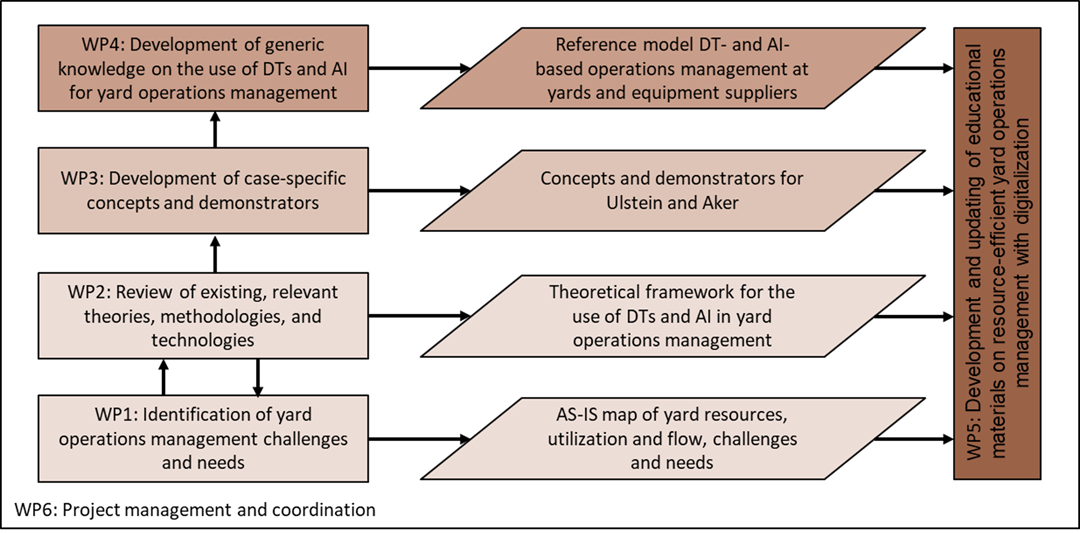

The specific objectives in TWinYards

- Map the AS-IS situation, needs, and challenges at Norwegian yards with respect to resources, resource planning, resource efficiency, and flow.

- Develop a theoretical framework for the use of digital twins and artificial intelligence to support yard operations management.

- Develop case-specific concepts and demonstrators for digital twin- and artificial intelligence-based yard operations management.

- Develop a reference model for digital twin- and artificial intelligence-based yard operations mangement to achieve resource efficiency and flow

- Develop and update educational materials on digitalized yard operations management.

The secondary objective of TWinYards is to develop knowledge on how to achieve resource efficiency and flow in the Norwegian yard industry by exploiting digital twins and artificial intelligence to support yard operations management.