The core technology is a novel dry-low emission combustion technology (DLE H2) capable of handling mixtures of natural gas and hydrogen with concentrations up to 100% H2.

New combustion technology

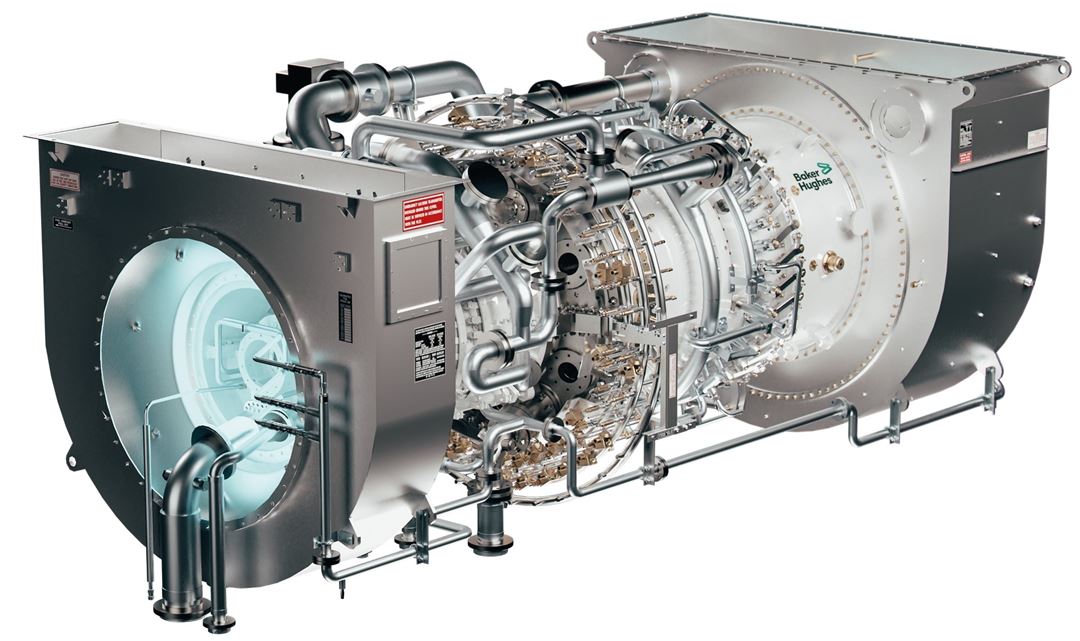

The combustion technology has been successfully validated at TRL5 (early 2021) retrofitted on the combustion system of a 13 MWe industrial gas turbine (NovaLT12). Besides ensuring low emissions and high efficiency, the DLE H2 combustion technology offers fuel flexibility and response capability on a par with modern gas-turbine engines fired with natural gas.

The new technology will be fully retrofittable to existing gas turbines, thereby providing opportunities for refurbishing existing assets in industry (CHP) and offering new capacities in the power sector for load levelling the grid system (unregulated power) and for mechanical drives. The DLE H2 technology adheres to the strictest specifications for fuel flexibility, NOx emissions, ramp-up rate, and safety, stated in the Strategic Research and Innovation Agenda 2021-2027.

The new DLE H2 combustion technology will be further refined and matured and, towards the end of the project, demonstrated at TRL7 on a 16.9 MWe gas-turbine engine (NovaLT16) fired with fuel blends mixed with hydrogen from 0-100% H2.

Within this wide range, emphasis is placed on meeting pre-set targets for:

- Fuel flexibility and handling capabilities,

- Concentration of hydrogen fuel during the start-up phase,

- Ability to operate at varying hydrogen contents,

- Minimum ramp speed, and

- Safety aspects pertaining to any level with regard to related systems and applications targeting industrial gas-turbine engines in the 10-20 MWe class.

A digital twin will be developed to simulate performance and durability characteristics, emulating cyclic operations of a real cogeneration plant in the Italian paper industry.

SINTEFs role in the project

- Project coordinator and manager, leading Work Package 1 (Project management)

- WP2 leader (Modelling assessment of DLE H2 combustion system) and performs a detailed analysis to improve present semi-empirical correlations of the turbulent burning rate for hydrogen-air flames at high-pressure and intense-turbulence conditions, which are specifically relevant for the DLE H2 combustion system in the NovaLT16 gas turbine. The outcome of this work will be used to characterize the combustion system in terms of thermoacoustics and assess the combustion system stability and the composition of exhaust gases.

- Task leader 4.3 SINTEF (Risk analysis and risk management) which will identify and analyze all known failure modes and failure effects, as well as accident scenarios for the retrofitted gas turbines and their immediate operational environments.