The evolution of nuclear science and increased awareness in the effect of radiation exposure on humans, have led to the need of new methods and instrumentation in radiation detection. The use of advanced radiation detectors is of vital importance for our society and their application expands from the medical field, radiation protection, environmental monitoring, renewable energy to security and counter terrorism.

Out of the many sources of radiation, Neutrons are proving to be the most challenging to detect. Neutron detection still heavily relies on early sensor technologies based on gas detectors. These devices present many shortcomings that need to be addressed. The miniaturization of gas detectors to achieve the higher spatial resolution required in modern applications is only possible to a limited extent. These devices are bulky and typically operate at high voltages with high power consumption. Additional issues arise with some of the gases used for neutron conversion, like He3 and BF3. The former is a by-product of the purification of tritium to produce nuclear weapons and is today extremely scarce and expensive. The latter is extremely toxic and dangerous. It is therefore crucial to find new ways of neutron detection with a positive environmental impact as well as the preservation of natural resources.

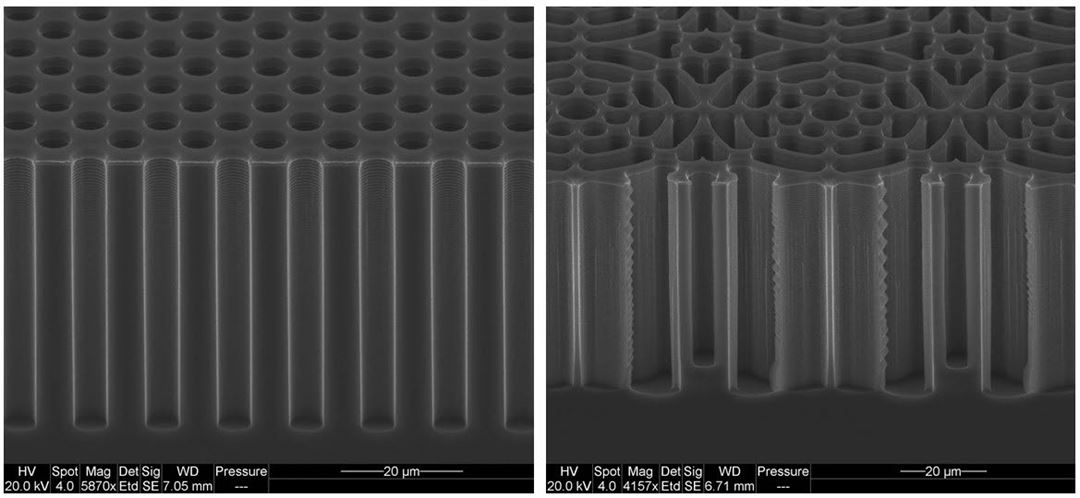

This project will also make use of the advancements in silicon micro-machining and modern material deposition to produce novel solid-state neutron detectors featuring 3-dimensional micro-structures filled with neutron converting materials. This approach will deliver increased neutron detection efficiency with reduced power consumption and state-of-the-art spatial resolution. This technology has the potential to revolutionize neutron detection and will allow the development of new scientific instruments and techniques for neutron imaging, neutron scattering, neutron tomography, radiation monitoring and medical application.