Scandium technological applications are unique, as it is a key component in producing Solid Oxide Fuel Cells (Scandia-Stabilized-Zirconia solid electrolyte layer) or high strength Aluminum alloys used in aerospace and 3D printing applications (SCALMALLOY®). Yet Scandium supply is limited due to its scarcity and the high cost of its production, which currently takes place in Asia and Russia.

Europe has no production of Scandium, but is home to many Sc industrial end-users (Airbus, II-VI, KBM Affilips and others). In fact, end-users like Airbus, are not deploying their Sc applications due to the lack of a secure Sc supply.

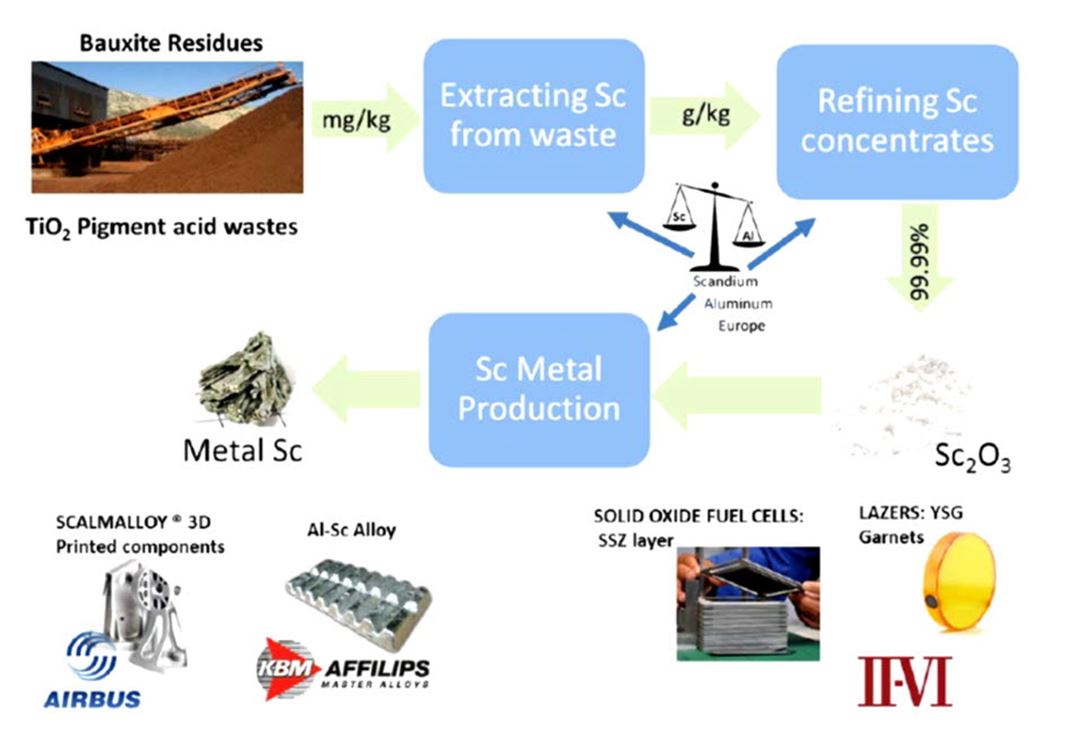

The main aim of the SCALE project is the efficient exploitation of EU high concentration Sc containing secondary resources including Bauxite Residues (BR) resulting from alumina production and acid wastes from TiO2 pigment production to develop a stable and secure EU scandium supply chain to serve the needs of EU aerospace and high tech industry.

Bauxite Residues (BR) from alumina production (5 Million tons on dry basis per year in Europe) and acid wastes from TiO2 pigment production (1.4 Million tons on dry basis per year in Europe) have Sc concentrations which are considered exploitable, given a viable extraction technology. SCALE develops and demonstrates the value chain starting from residue and finishing to high tech end-product. In more detail:

- SCALE develops innovative technologies that can extract economically and sustainably Sc from dilute mediums (<100 mg/L) and upgrade them to pure oxides, metals and alloys at lower energy or material cost.

- SCALE extracts along with Sc all other REEs found in the by-products (AoG's BR on an annual base contain 10% of the European REE raw material imports)

SINTEF will contribute in the development of innovative reduction technologies to produce Sc metal and Sc-Al alloys by high-temperature electrolytic processes using oxide raw materials obtained by the extraction processes developed in the project. The reduction technologies are based on state of art methods, i.e. electrochemical de-oxidation, or FFC-Cambridge process, and Hall-Heroult process for primary Al production, applied from an innovative perspective.

Partners:

The industrially driven SCALE consortium covers the entire Sc value chain with 7 major European industries and further features 8 academic and research institutes and 4 engineering companies with track records in RTD. In total, 18 partners from 10 different EU-countries, included Switzerland:

- ALOUMINION AE, Greece, Coordinator

- II-VI DEUTSCHLAND GMBH, Germany

- NATIONAL TECHNICAL UNIVERSITY OF ATHENS, Greece

- RHEINISCH-WESTFAELISCHE TECHNISCHE HOCHSCHULE AACHEN, Germany

- KUNGLIGA TEKNISKA HOEGSKOLAN, Sweden

- BUDAPESTI MUSZAKI ES GAZDASAGTUDOMANYI EGYETEM, Hungary

- BUNDESANSTALT FUER MATERIALFORSCHUNG UND -PRUEFUNG, Germany

- FACHHOCHSCHULE NORDWESTSCHWEIZ, Switzerland

- FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V., Germany

- MEAB CHEMIE TECHNIK GMBH, Germany

- STIFTELSEN SINTEF, Norway

- IOLITEC IONIC LIQUIDS TECHNOLOGIES GMBH, Germany

- KBM MASTER ALLOYS BV, Netherlands

- LESS COMMON METALS LIMITED, United Kingdom

- TRONOX PIGMENTS (HOLLAND) BV, Netherlands

- ALUMINIUM OXID STADE, GESELLSCHAFTMIT BESCHRANKTER HAFTUNG, Germany

- ITRB LTD, Cyprus

- WAVESTONE LUXEMBOURG S.A., Luxemburg

This project has received funding from the European Union's Horizon 2020 research and innovation programme under GA No. 730105.