Important activities are:

- optimization of the filament winding production process

- developing a framework for a numerical "design toolbox" specialized for filament wound composite pressure vessels

- investigate new approaches for design and layup of glass and carbon fibres in hybrid composite pressure vessels

- build understanding of failure mechanism in suchlike vessels

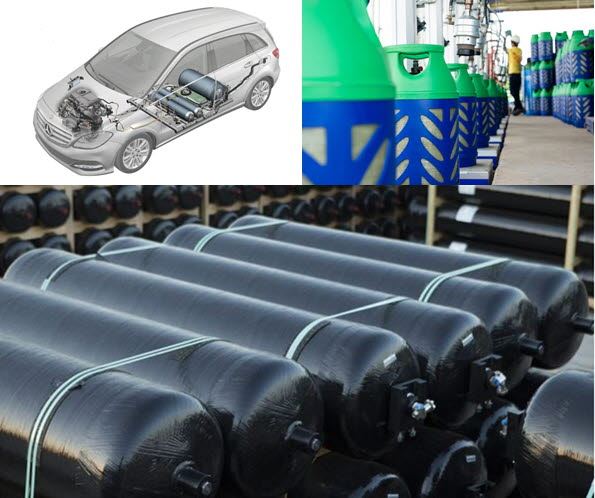

Composite pressure vessels are today increasingly used in a number of applications due to a favorable combination of reduced weight, low maintenance and improved mechanical properties compared to the classical metal vessels. This project focusses on CNG (Compressed Natural Gas) and LPG (Liquid Petroleum Gas) composite pressure vessels for automotive and private applications, where HEXAGON Raufoss and Ragasco respectively are leading manufacturers.

The overall aim of this project is to develop new and optimized design methods, production processes and supporting tools specialized for composite gas pressure vessels. The research will be focused on reduction of component costs, improving product performance and increasing production rates. The ambition is to increase market shares in current markets and to grow into new market areas.

The current design and production process of these components, and in particular the composite shell, can be optimized to achieve improved product performance and manufacturing/cost efficiency. The design of the composite layup, selection of fibre types and winding process parameters is a very complex task involving a large number of parameters. Thus, the implementation of state-of-the-art numerical models and methods for use in the development phase are critical to ensure a competitive line of products for the future. Current filament wound composite design suffers from large structural safety factors leading to reduced margins of profit and increased environmental impact.

Through a combination of experimental evaluation of product and material performance and detailed analysis of failure mechanisms combined with advanced finite element analysis (FEA) and specialized tools for filament winding design, a framework for a "design toolbox" for composite pressure vessels will be developed, thus providing the proper bases for the design of the next generation of pressure vessels.

The project is partially financed by the Norwegian Research Council through the BIA IPN program. The consortium consist of the industrial partners HEXAGON Raufoss (project owner) and HEXAGON Ragasco, and the research institutions SINTEF Material and Chemistry (projectleader Einar Louis Hinrichsen) and SINTEF Raufoss Manufacturing (contact person Steinar Sørbø).