Photovoltaics (PV) are decidedly the poster-child for the energy revolution with dominating mainstream exposure. While PV has existed for over 70 years, its adoption as a potentially significant contributor to energy needs has only started to ramp up in the last 10 – 15 years. With such a recent market boom, most attention has been focused on production and deployment, which has grown exponentially in the last decade. Therefore, since inception of the PV technologies (1980), the total PV products disseminated throughout Europe represent now roughly 8 million tons of future PV waste!

In terms of waste flow management roadmap, the below shows the expected annual tonnage of end of life modules until 2020 i.e. at the time where the CABRISS project's outcomes will be available.

These forecasts considered that, even if PV modules are guaranteed up to 25 years, many users replace their PV installations before this theoretical end of life in order to take advantage of higher yields due to new technological improvements found in more recent modules. Such a behavior ends up with an average life span of 17 years for PV modules.

In addition to these products lifecycle considerations, a shorter term challenge for a PV waste recycling value chain targeted by CABRISS is to deal with the waste coming from installation breakage and production scrap which create a very large percentage of decommissioned panels and this will continue over the upcoming years as the quantity of installed capacities will continue to increase.

As an example, in 2012, the 17.7 GW installed capacity in Europe has generated around 27000 tonnes of waste from installation breakage (estimated rate 2%) and production scrap (estimated rate 1-2%).

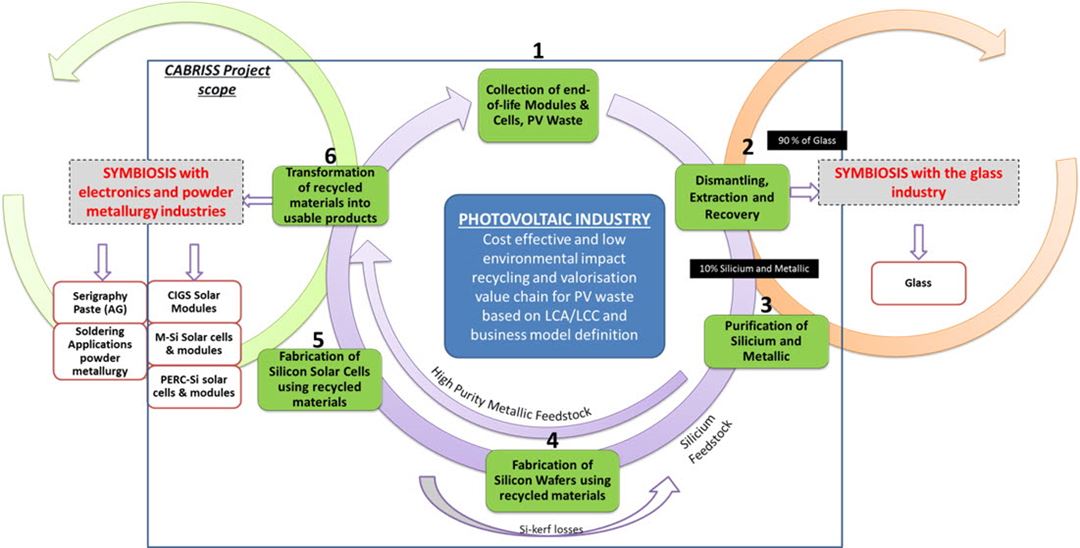

Hence, the PV waste coming from both the production scraps and the end-of-life products will ideally have to be dismantled and inserted into a recycling industrial process in order to let all the raw materials be retrieved and input back onto the market.

According to the above mentioned studies, a well-established PV waste recycling loop would have both an economic and an environmental incentive: a double green effect for production scraps as an immediate need and for used PV modules as an increasing necessity for the upcoming 10 to 15 years.

The circular production value chain is displayed on Figure below. It illustrates how the project will consider all types of Si scraps and where they will be re-introduced in the value chain in order to make a zero-waste ecosystem.