The smartphone, electric cars, hydrogen storage, wind turbines. The technology needed for our modern life and a greener society depends on a just a handful of raw materials. A few decades ago they were largely hidden and unknown – now suddenly they have become crucial.

You may have heard of rare earth elements that are almost exclusively mined in China? Or seen pictures of cobalt mines in the Congo? There are many reasons why more sources for these materials are needed. Concern for a safe working environment, security of supply, politics and shifting trade agreements are just some.

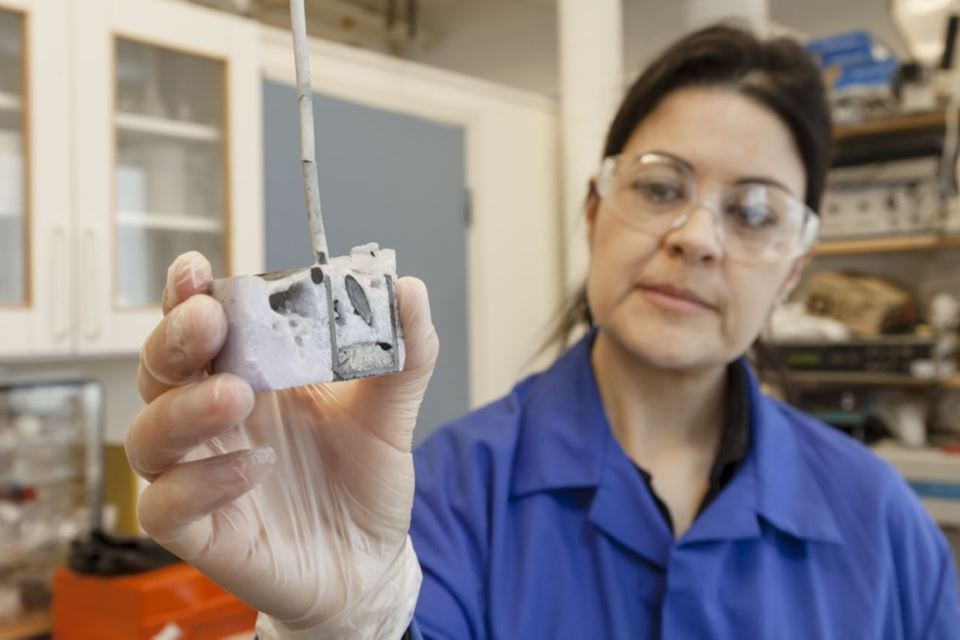

Ana Maria Martinez, senior researcher at SINTEF Industry, leads one of the projects attempting to find good European recycling solutions that can provide access to more of these critical raw materials. She works in the metal production and processing department and is an expert in high-temperature electrolysis. Here she answers questions about critical raw materials, rare earth elements and the ongoing research.

Why do we need more raw materials?

All types of industries need raw materials. For example, processing industries need carbon, metals and other relatively common substances. But we need more and more raw materials because the world’s population is growing and we are developing more and more technologies.

What are “critical raw materials”?

These are materials for which there is a risk that demand will outstrip supply, and that will have a significant impact on the economy. This could be because the materials are only found in one region, because they come from areas with political instability, or because they rely on agreements that make it difficult to obtain enough of them.

There are different lists of critical raw materials. Among others, the EU and the USA update their lists approximately every two years, after all stakeholders have

gathered to discuss them. They then highlight the materials that are important for developing special types of technologies now and that exist only in one part of the world.

Many of the materials are needed for green technologies that are important today, such as electric cars. But critical raw materials are also used in smartphones and other electronic devices that we use daily.

Raw materials that come mainly from just one country are vulnerable if the trade agreements change – such as with China, which dominates the production of many of them – or if conditions in the country are difficult or unclear. An example of this is DR Congo, which has the bulk of the world’s cobalt resources. Among other uses, cobalt is needed for electric car batteries.

Which materials are we talking about?

The EU’s third list of critical materials from 2017 is the most recent. The list of materials follows, along with the country that produces the most of each one.

- Antimony (China 87 percent)

- Baryte (China 44 percent)

- Beryllium (USA 90 percent)

- Bismuth (China 82 percent)

- Borates (Turkey 30 percent)

- Cobalt (DR Congo 64 percent)

- Coke (China 54 percent)

- Fluorospar (China 64 percent)

- Gallium (China 73 percent)

- Germanium (China 67 percent)

- Hafnium (France 43 percent)

- Helium (USA 73 percent)

- Indium (China 57 percent)

- Light, rare earth elements: lanthanum, cerium, praseodymium, neodymium, (China 95 percent)

- Magnesium (China 87 percent)

- Natural graphite (China 69 percent)

- Natural rubber (Thailand 32 percent)

- Niobium (Brazil 90 percent)

- Phosphorite (China 44 percent)

- Phosphorus (China 58 percent)

- Platinum metals: ruthenium (South Africa 93 percent), rhodium (South Africa 83 percent), palladium (Russia 46 percent), osmium and iridium (South Africa 85 percent) and platinum (South Africa 70 percent)

- Scandium (China 66 percent)

- Silicon (China 61 percent)

- Tantalum (Rwanda 31 percent)

- Heavy, rare earth elements: yttrium, europium, gadolinium, terbium, dysprosium, holmium, erbium, ytterbium and (China 95 percent)

- Tungsten (China 84 percent)

- Vanadium (China 53 percent)

Could there be new sources?

The primary source of critical raw materials is mining. Here, Norway has opportunities. For example, The Fen Complex in Telemark has what could be Europe’s largest deposits of rare earth elements. But it takes time to investigate and get started with such new projects, and new mining operations are rarely popular.

The materials can also come as by-products of production that exists today, but are(?) not used. For example, SINTEF works with Yara on a project to look at the many rare earth elements that are by-products of fertilizer production.

In the next phase, the project will look at how much more can be obtained from so-called “urban mining”, the reclaiming of raw materials from used electrical products, buildings and waste.

What is the role of researchers?

First and foremost, they are trying to find technologies that make it possible to recover these elements in the most cost-effective and environmentally efficient way.

They are also trying to create awareness and debate around the topic. Most people will agree that materials should be recycled so that critical raw materials can be reused, but few will want the collection and recycling facilities close to their home.

People are not so good at delivering the products, either. In Sweden, Nokia requested that people send their old mobile phones for recycling. Most people responded by asking why they should do it – they want to keep it in a drawer in case something happens to their new one.

Technology alone is not enough – systems are also needed to collect the products from which the materials can be extracted. To aid this, researchers also want to influence politicians.

Can Europe be self-sufficient?

It’s not impossible. We are talking about meeting a great demand for raw materials, and that demand is increasing rapidly as time passes. But there are many initiatives trying to find a solution to this.

The EU supports a lot of research in this area through today’s Horizon 2020 program. We expect that support to continue in the upcoming Horizon Europe program.

The EU’s support aims to find mines that can be exploited and to develop technology that can recover critical raw materials from different types of waste. SINTEF is involved in many such projects.

What research is happening now?

SINTEF coordinates two projects on rare earth elements: Rare Earth Recycling for Europe (REE4EU, www.ree4eu.eu) and Secure European Critical Rare Elements (SECREETS, www.secreets.eu).

- SINTEF is also a partner in several other projects:

- SCALE (www-scale-project.eu), on the recycling of scandium

- PLATIRUS (www.platirus.eu), on platinum metals (platinum, palladium, and rhodium,)

- TARANTULA (h2020-tarantula.eu), on tungsten, tantalum and niobium

- CROCODILE (h2020-crocodile.eu), on cobalt

What is REE4EU?

Ana Maria Martinez, Senior Researcher at SINTEF Industry, coordinates REE4EU. Together with Elkem and 12 other partners in Spain, the UK, Germany, France, Sweden and Belgium, SINTEF works to recover rare earth elements from magnets and used batteries, for use in the production of electric and hybrid cars.

Today the magnet industry is one of the industries that are suffering most from the Chinese control of rare earth elements.

In this project, a complete closed-loop permanent recycling process has been demonstrated at pilot scale for the first time. In addition to trying out the recycling process in practice, the partners have analysed the market to see how the process can be made both profitable and environmentally-friendly.

Although the amount of waste is large, the content of the coveted materials is relatively small. For example, the rare earth elements make up only 0.02 percent of the total weight of a smartphone. For a typical smartphone, that equates to somewhere between 25 and 40 milligrams.