The Food and Agriculture Organization of the UN estimates that a third of all food produced on the planet is wasted. This isn’t simply just an economic or ethical problem, but also causes major environmental damage due to greenhouse gas emissions.

In industrial countries, most waste is generated in retail outlets and households. One reason for this is that food is stamped with inaccurate “best before” dates, which mean that both retailers and consumers throw away perfectly edible food.

FACTS:

The EU project called NanoBarrier (2012-2016).

9.9 million euros. 15 research partners from ten countries. SINTEF Materials and Chemistry is acting as Project Coordinator.

However, four years ago an EU project was launched with the aim of developing plant-based bioplastic packaging that not only extends the shelf life of foods, but also contains a sensor that notifies retailers and consumers of when the food inside is really no longer fit to eat. Today, Åge Larsen at SINTEF is ready to present the first demonstration packaging – made of PLA (polyactic acid) and bio-PET (polyethylene terephthalate).

‘Green’ plastic

“The packaging is made of biopolymers to which we have added nanoparticle components”, says Larsen. “This provides the packaging with new and improved food preservation properties. It is designed mainly to protect the contents from their surroundings and thus extend shelf life. We achieve this by means of improved oxygen barriers. Standard plastic packaging allows the entry of air which places restrictions on shelf life. Moreover, the new approach considerably reduces the carbon footprint”, he says.

Larsen says that the use of plant-based polymers is an expanding field. For example, biodegradable PLA is manufactured by cultivating carbohydrates via bacteria, while bio-PET are macromolecules derived from plant residues.

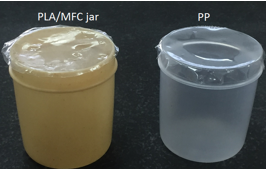

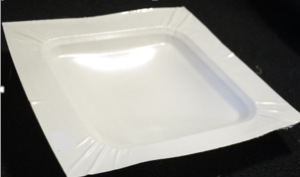

A blow-moulded bottle, pots designed to hold seafoods and a cellulose-based film used as food bowl, are three of the prototypes in the project. Photoes: SINTEF

Click to open

Four prototypes

The Portuguese-based company Logoplaste, in collaboration with SINTEF and other research partners, has developed a blow-moulded bottle, while the Greek project partner Argo has developed a pot designed to hold seafood such as crabs and prawns. Both types of container are covered with an oxygen-proof exterior coating developed by SINTEF.

In addition, a three-layer coating has been developed consisting of a cellulose-based film sandwiched by two biodegradable biopolymer layers that serve as oxygen barriers. This can be utilised in the same way as the rigid plastic currently used as food bowls.

The fourth prototype produced as part of this project is a blow-moulded film. This is essentially plastic foil similar to that used to make plastic bags and as oxygen-protective coverings for plates containing food.

Sensors

The researchers have also developed sensors that can detect, for example, whether the temperature of the food has become too high or if a product has soured. One type of sensor consists of nanocapsules containing signal substances. If the temperature becomes too high or the pH value anomalous, the capsule shells decompose and release the signal substances.

“The sensors are sensitive to small changes and the packaging will change colour when the substances are released”, says Larsen. “It might be embarrassing for a food retailer to be faced with rows of red flashing lights, so we envisage developing substances that are not necessarily visible to customers when they are released. Manufacturers, on the other hand, will be able to use direct-reading instruments”, he says.

Larsen tells us that there will always be an issue regarding how the sensors are incorporated into the product. This must be a decision of the manufacturer. Sensors installed on the inside of the packaging and in contact with the food, such as in bottle caps or corks, will have to be approved by the food hygiene authorities.